Manganese carbonate (MnCO₃) is used as a manganese source in steel manufacturing. In steel production, manganese is essential for properties such as strength, toughness, and deoxidation. This blog explains how manganese carbonate works in steelmaking, its chemical properties, specific applications, standards, and comparative advantages relative to other manganese sources.

II. Role of Manganese in Steel Manufacturing

Steel manufacturing uses manganese for several functions. Below are key roles, with data and standards.

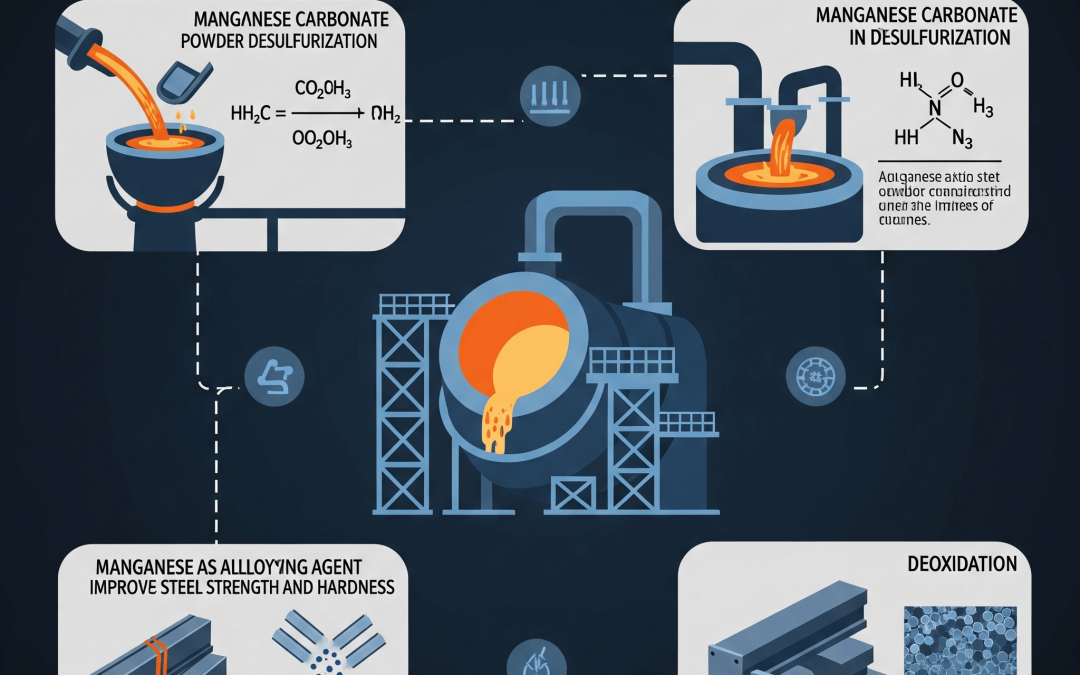

1. Deoxidation, Desulfurization, and Impurity Control

Manganese binds with sulfur. It forms manganese sulfide (MnS), which has a high melting point, reducing cracking in hot rolling.

It acts as a deoxidizer: reaction with oxygen removes it from molten steel, avoiding oxide defects.

2. Alloying Element: Strength, Hardness, Toughness

Adding manganese improves tensile strength and hardness. For example, in carbon-manganese steels (“C–Mn steels”), manganese content typically ranges 1.00% to 1.65% by weight. Standards like ISO 4948-1 and ASTM A941 limit manganese in unalloyed (carbon) steels to maximum ~1.65% Mn.

Carbon-manganese steels (with up to ~1.8% Mn) are used in structural steels, where more Mn gives more strength but there is trade-off with ductility.

3. Types of Steel and Manganese Amounts

Some examples:

| Steel Type | Typical Mn Content (%) | Typical Carbon Content (%) | Use Case |

|---|---|---|---|

| Carbon-Manganese Structural Steel | ~1.0-1.65% | up to ~0.25% | Buildings, structural sections |

| Mild Steel / Low Carbon Steel | ~0.3-1.0% | 0.05-0.25% | General structures, welding friendly |

| High Manganese Steel (Hadfield Steel) | ~12-14% | higher C (e.g. ~1.0-1.4%) | High impact / wear applications: railway, rock crushers |

4. Global Demand Numbers

Steelmaking consumes about 80%-90% of global manganese production.

In 2020, global crude steel production was ~1.88 billion metric tons. Most manganese use is tied to that scale.

III. Chemical Properties of Manganese Carbonate Relevant to Steelmaking

Understanding what MnCO₃ does chemically and physically is important to see its utility in the steel‐industry feedstock.

| Property | Value / Description |

|---|---|

| Chemical formula | MnCO₃ (Manganese(II) carbonate) |

| Molecular weight | ~ 114.95 g/mol |

| Appearance / Purity | Light pink to white powder. Industrial grades often ≥ 99% pure; high-purity grades higher. |

| Manganese (Mn) content | ~ 43-44% Mn by weight (theoretical) in good quality manganese carbonate. |

| Density | ~ 3.12 g/cm³ at 25 °C |

| Decomposition (thermal) | Begins at ~200-350 °C, decomposes to MnO + CO₂ under heating. |

| Solubility | Very low in water (negligible or slight), soluble in dilute acids. |

Thermal Decomposition

Studies (e.g. Thermal Decomposition Kinetics of Manganese Carbonate) show decomposition activation energy ~ 65-68 kJ/mol.

The exact temperature at which decomposition completes (terminative temperature) depends on heating rate; higher heating rate tends to increase that temperature.

Reaction Mechanism in Steelmaking Context

When MnCO₃ is added into high-temperature environments (e.g. in furnace or during fluxing), it decomposes:

The MnO (manganous oxide) then participates in melting slag, deoxidation, or alloy addition, depending on steelmaking process.

IV. Applications of Manganese Carbonate in Steel Manufacturing

These are concrete ways MnCO₃ is used, with data / standards / comparisons to other manganese sources (e.g. MnO₂, manganese ore).

1. As a Source of Manganese Oxide (MnO) in Smelting / Blast Furnace / EAF

MnCO₃, when calcined/decomposed, gives MnO. That oxide is used in the slag and molten steel to add manganese element.

It is useful when the steelmaker wants a relatively clean manganese input, with fewer impurities (e.g. lower sulfur, phosphorus) than raw ores.

2. Alloy Steel Production

For steels where Mn content is substantial (e.g. Hadfield steel ~ 12-14% Mn, or medium/high manganese steels for special applications), the source used must be high purity. MnCO₃, if purified, can meet that requirement.

Also, it gives control over manganese content since its Mn is predictable.

3. Deoxidizing and Fluxing Agent

In secondary steelmaking, adding compounds that deoxidize steel is critical. MnO (derived from MnCO₃) helps combine with oxygen.

Fluxing: Mn compounds help adjust slag chemistry, lowering melting point of unwanted compounds, improving slag fluidity.

4. Impurity Control: Sulfur and Phosphorus

Mn combines with sulfur, forming MnS which is less harmful than free sulfur. Helps prevent hot shortness.

Phosphorus control is aided indirectly (through slag behaviour) but main benefits are from sulfur and oxygen control.

V. Advantages of Manganese Carbonate vs Other Manganese Sources

To see when MnCO₃ is preferable, here’s a comparative table: MnCO₃ vs MnO₂ vs Manganese Ore (including low-grade mineral ores).

| Feature | MnCO₃ | MnO₂ | Manganese Ore (e.g. low-grade ore) |

|---|---|---|---|

| Purity / Impurity Load | Relatively low impurities if purified; less sulfur, phosphorus than many ores. | MnO₂ can be very pure but often requires more processing / oxidation states. | Often higher impurities: P, S, silica, etc. |

| Predictability of Composition | High – well characterized; composition stable. | Moderate – requires oxidation / reduction, variances in oxide states. | Variable – ore quality fluctuates by source. |

| Ease of Handling / Processing | Decomposes at moderate heat; manageable in furnaces; predictable MnO yield. | Requires more handling; maybe additional energy to reduce / convert. | Ore may need crushing, washing, beneficiation; more variable input. |

| Cost (Raw Material + Processing) | Depending on local availability, can be cost-competitive; processing cost may be lower for high-purity grades. | Often higher oxidation state; more energy for processing to usable form. | Raw ore may be cheaper per ton but quality and transport and beneficiation raise cost. |

| Reaction / Thermal Behaviour | Decomposes at ~200-350 °C; good control; less risk of unwanted oxide phases if controlled. | Might require higher temps / controlled conditions to get desired phase. | Mineral ores may contain mixed manganese oxides; unpredictable behaviour in slag or furnace. |

| Use in Special Steel (high Mn content) | Better suited if high-purity specification is required. | Could be used but may need more refining. | Less suited unless upgraded. |

The precise numbers will depend on supplier, location, local energy, and purity specs.

VI. Standards, Grades, and Quality Requirements

For steelmaking, manganese source materials must meet standards. Though specific standards seldom mention “manganese carbonate” explicitly, the steel chemical composition standards reference maximum/minimum Mn in steel; raw materials (Mn compounds) must allow steel to meet those standards.

Some relevant standards / references:

ISO 4948-1: Defines categories of steels; unalloyed steels (carbon steels) are limited to Mn ≤ 1.65% for being non-alloy (basic carbon-manganese steels) in many cases.

ASTM A941: Similar constraints in US steel specification for carbon / alloy steel definitions.

Common Steel Grades: For example, ASTM A36 structural steel has ~1.03% Mn (maximum) in many versions.

Quality parameters for manganese carbonate when used in steelmaking might include:

Purity of MnCO₃ (e.g. ≥ 99% MnCO₃ or higher)

Mn content (ideally predictable, e.g., ~43-44% in MnCO₃)

Moisture content (low, e.g. ≤ 0.5%)

Impurities (P, S, heavy metals) below certain ppm (depends on steel grade)

Particle size distribution (powder vs granules), for better mixing and reaction kinetics

VII. Comparative Table: MnCO₃ vs Mn Sources in Steelmaking Context

Here is a simple direct comparison focusing on steelmaking relevant aspects:

| Source | Mn Content in Source | Impurity Risk* | Thermal Decomposition / Usable Form | Typical Use Case |

|---|---|---|---|---|

| MnCO₃ | ~ 43-44% Mn by weight (if pure) | Low, if purified; heavy metals, moisture, insoluble matter could be contaminants | Decomposes at ~200-350 °C → MnO + CO₂; usable in slag and molten steel | When steelmaker wants clean, predictable Mn input; for alloy steels or high-quality structural steels |

| MnO₂ | Higher oxidation state; Mn % somewhat lower due to oxygen; purity depends on processing | Possible residual moisture, partial oxides, leftover impurities | Requires reduction (often by carbon or other reducing agents) to usable MnO or metal; higher temp needed | For speciality applications; or as precursor in other Mn chemicals |

| Manganese Ore (low/medium grade) | Variable; could be lower than MnCO₃ per unit weight because of gangue, mixed oxides | Higher impurity risk: silica, phosphorus, sulfur, other minerals | Needs beneficiation, sometimes roasting/reduction; not as predictable in thermal behaviour | Bulk supply; when cost constraints dominate and purity less critical |

* Impurity risk includes contaminants that can degrade steel quality (e.g. P, S, heavy metals).

VIII. Challenges / Requirements for Using MnCO₃ in Steel Manufacture

While MnCO₃ has advantages, there are also practical considerations and requirements for its use.

Purity and Consistency

Steelmakers require very consistent Mn content and low contamination. Variations in moisture, impurity content (sulfur, phosphorus), particle size can affect melting, slag chemistry, final steel properties.

Supplier’s quality assurance and certificates (COA) are often required.

Thermal Behavior / Decomposition Control

The supply of heat and residence time must be enough to fully decompose the MnCO₃ to MnO (or other usable form) before or during alloy addition. Partial decomposition leads to unreacted carbonate which could produce CO₂/CO gases or lead to inefficiencies.

As noted, decomposition begins ~200-350 °C; but heating rates and furnace environment (oxidizing vs inert vs reductive) affect when and how completely decomposition occurs.

Compatibility with Existing Furnace / Process Conditions

The furnace temperature, slag chemistry, atmosphere (oxidizing or reducing), and whether electric arc furnace (EAF), basic oxygen furnace (BOF), or induction furnace all matter.

MnCO₃ (or its derived MnO) must integrate without causing undesired slag foaming, excessive CO₂ release at wrong time, or unwanted side reactions.

Cost of Transportation, Storage, Handling

MnCO₃ is often a powder; moisture control, packaging, shipping costs matter.

Storage must avoid humidity; the carbonate reacts with acids, moisture moderately.

Environmental / Regulatory Requirements

Emissions of CO₂ during decomposition. Must comply with local environmental laws. Potential for CO / CO₂ control.

Impurity levels, especially heavy metals, must satisfy environmental / health safety regulations if they may end up in steel or slag by-products.

IX. Case / Data Examples

Here are some specific data / examples that illustrate how MnCO₃ is or can be used in steel manufacture, or what properties of steels are achieved when using manganese.

Carbon-Manganese Steel Properties: Typical carbon-manganese steels have up to ~1.8% Mn; steel standards permit up to ~1.65% Mn in non-alloyed steels. manganesesupply+1

High Manganese Steel (Hadfield Steel): Contains ~12-14% Mn, often used for wear-resistance. If using MnCO₃, you need raw material that after conversion gives that high Mn content. Metal Zenith

Global Steel and Manganese Demand: In 2020, world crude steel production ~1.88 B metric tons; manganese ore production and manganese materials are tightly related: steel industry consumes majority of manganese supplies.

IX. Case / Data Examples

Here are some specific data / examples that illustrate how MnCO₃ is or can be used in steel manufacture, or what properties of steels are achieved when using manganese.

Carbon-Manganese Steel Properties: Typical carbon-manganese steels have up to ~1.8% Mn; steel standards permit up to ~1.65% Mn in non-alloyed steels.

High Manganese Steel (Hadfield Steel): Contains ~12-14% Mn, often used for wear-resistance. If using MnCO₃, you need raw material that after conversion gives that high Mn content.

Global Steel and Manganese Demand: In 2020, world crude steel production ~1.88 B metric tons; manganese ore production and manganese materials are tightly related: steel industry consumes majority of manganese supplies.

X. Conclusion

Manganese carbonate is a viable and often advantageous source of manganese for steel manufacturing, especially when steelmakers demand high purity, predictable composition, and control over impurity load. Its chemical properties (decomposition to MnO + CO₂ at moderate temperatures, high Mn content) make it suitable for alloy steels, deoxidation, desulfurization, and fluxing. When compared with other sources like MnO₂ or unrefined ores, MnCO₃ often offers better consistency and lower impurity risk, though cost, handling, and furnace compatibility are factors.

If you are a steel manufacturer or raw material supplier considering manganese carbonate, ensure your supply meets high standards (purity, moisture, heavy metal limits) and that your process can handle its thermal behavior.

FAQs

Q1: Why is manganese important in steel manufacturing?

Manganese improves strength, hardness, and toughness. It also removes impurities like oxygen and sulfur by forming stable compounds such as manganese sulfide (MnS).

Q2: How does manganese carbonate work in steelmaking?

At high temperatures, manganese carbonate (MnCO₃) decomposes into manganese oxide (MnO) and carbon dioxide (CO₂). The MnO then contributes manganese to the molten steel and slag, improving steel quality.

Q3: What are the advantages of using manganese carbonate over manganese ore?

Manganese carbonate is more predictable in composition, has lower impurity levels, and decomposes at moderate temperatures. In contrast, ores often have higher impurities like sulfur and phosphorus.

Q4: What is the manganese content of manganese carbonate?

Pure manganese carbonate contains about 43–44% manganese by weight.

Q5: Which steel types commonly use manganese?

Carbon-manganese steels (1.0–1.65% Mn)

Mild steels (~0.3–1.0% Mn)

High manganese steels (Hadfield steel, ~12–14% Mn)

Q6: Are there standards that regulate manganese in steel?

Yes. For example, ISO 4948-1 and ASTM A941 define limits for manganese in non-alloyed steels, usually up to 1.65% Mn.

Q7: What challenges exist when using manganese carbonate in steelmaking?

Key challenges include ensuring high purity, consistent Mn content, managing CO₂ emissions from decomposition, and matching furnace conditions for proper conversion to MnO.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.