You use manganese dioxide welding rods because they help your welding electrodes make a steady arc and build a tough, safe slag. These rods make welding better. They also protect welding electrodes from rust, water, and damage. This keeps your welds neat and strong.

Manganese dioxide welding rods help keep the arc steady. They also lower harmful fumes. This makes your welds stronger. It also makes your workspace safer.

These rods make a strong slag that is easy to remove. The slag keeps dirt and air away from the weld. This gives you cleaner and neater welds.

Using manganese dioxide rods makes welds better. They help make fine and even grains. The welds are tough and do not crack easily. They also last longer.

Role in Welding

Arc Stability

A stable arc is important when you weld. Manganese dioxide welding rods help keep the arc steady. The coating on these rods controls electricity flow. This gives you a smooth arc that does not jump or stop. Your welds become stronger and more dependable. Using manganese dioxide welding rods also makes less welding fume. Less fume means your workspace is safer.

Tip: Keeping the arc steady helps you make fewer mistakes and keeps your welds neat.

Slag Formation

Slag covers your weld and makes cleaning easier. Manganese dioxide in welding electrodes reacts when it gets very hot. It forms manganese oxides like MnO and MnO2. These oxides mix with silicon dioxide and make manganese silicates. The silicates become part of the slag on your weld.

Manganese oxides form when welding gets hotter than 1500°C.

These oxides mix with silicon dioxide to make manganese silicates.

Slag catches dirt and keeps air away from the weld.

Manganese dioxide welding rods help make strong, easy-to-remove slag.

You see less welding fume when slag forms the right way.

If you use welding electrodes with less manganese, you might see more gray spots and problems. Manganese helps stop these issues by making slag that keeps your weld clean.

Protection and Deoxidation

You want your welds to last a long time. Manganese dioxide welding rods protect welding electrodes from rust, water, and damage. The coating works like a shield. When you weld, manganese acts as a deoxidizer. It takes away oxygen and sulfur from the weld pool.

Manganese grabs oxygen and forms MnO when it is hot.

MnO mixes with other oxides and makes your weld stronger.

Manganese also grabs sulfur and forms MnS, which helps stop cracks.

These things make your weld tougher and better.

You get fewer bad spots and a cleaner weld.

When you use manganese dioxide welding rods, you see less welding fume. The coating keeps air away from the hot metal. Your welding electrodes stay safe, and your welds stay strong.

Benefits of Manganese Dioxide Welding Rods

Weld Quality

You want your welds to look good and stay strong. Manganese dioxide welding rods help you get better weld quality than many other options. When you use these rods, you see smoother weld shapes and more even metal flow. The manganese in the coating helps form fine grains in the weld. This makes the weld look uniform and reduces the chance of weak spots.

Using welding electrodes with more manganese gives you:

Finer and more even grain structure in the weld.

Fewer defects and cleaner weld seams.

Higher yield strength and tensile strength.

More uniform hardness across the weld.

You also get more reliable results when you use the right welding current. If you use too little current, the weld may look rough. When you use enough current with manganese dioxide welding rods, your welds become cleaner and stronger. The manganese-rich phases in the weld help dissolve impurities and make the grains even finer. This means you get a weld that is both tough and neat.

Mechanical Properties

You need your welds to be tough and last a long time. Manganese in welding electrodes helps form a special structure called acicular ferrite. This structure has needle-shaped grains that lock together. It makes your welds stronger and helps stop cracks from spreading. You get higher tensile strength and better toughness in your welded joints.

Mechanical tests show that welds made with manganese dioxide welding rods can reach a tensile strength of up to 483 MPa. The uniform grain structure helps your weld resist breaking under stress. However, more manganese can make the weld a little less flexible. It can also make welding a bit harder because it increases carbon in the weld. Still, the benefits for strength and toughness are clear.

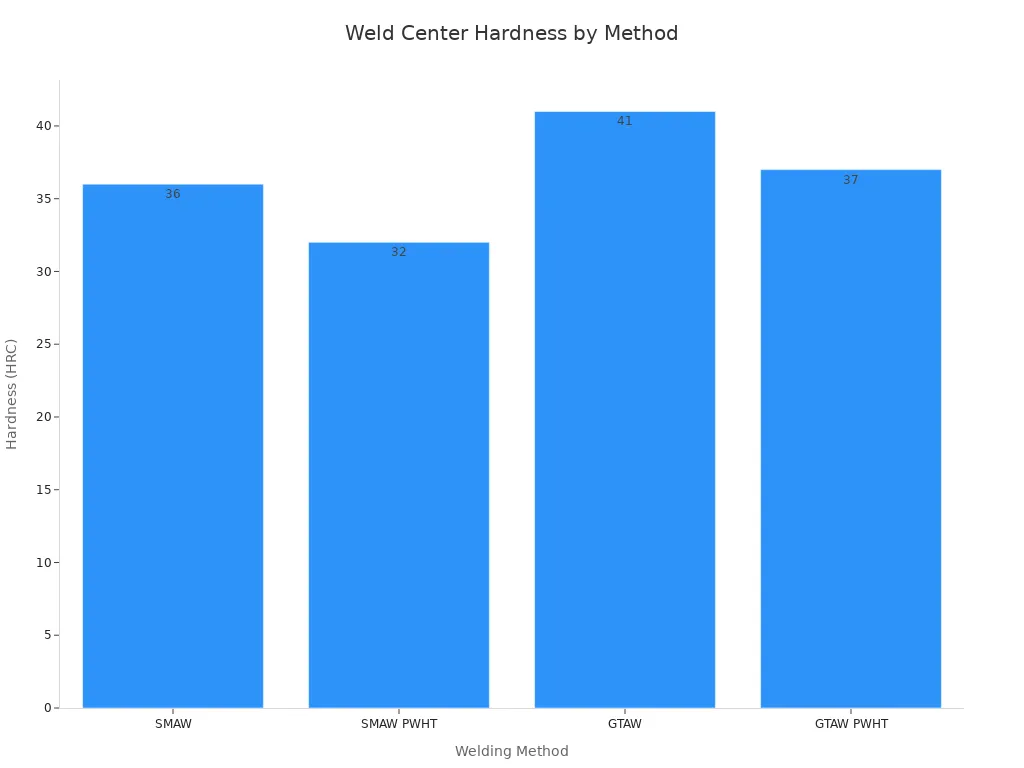

You can see the difference in hardness values between different welding methods and coatings. The table below shows how weld center hardness compares:

Welding Method | Weld Center Hardness (HRC) |

|---|---|

SMAW | 36 |

SMAW PWHT | 32 |

GTAW | 41 |

GTAW PWHT | 37 |

Note: SMAW rods usually have manganese dioxide coatings. GTAW uses different filler rods. Post weld heat treatment (PWHT) lowers hardness in both cases.

Slag Removal

You want to spend less time cleaning your welds. Manganese dioxide in welding electrodes helps form a slag that is easy to remove. The slag covers the weld and protects it from air while it cools. When you finish welding, you can chip or brush off the slag without much effort.

Easy slag removal means you get a cleaner weld surface. You see fewer trapped impurities and less need for extra cleaning. This helps you work faster and keeps your welds looking professional. The right slag also protects the weld from moisture and air, so your welds stay strong and free from rust.

Tip: Always let the slag cool before removing it. This keeps your weld safe and makes cleaning easier.

You get these benefits every time you use manganese dioxide welding rods with your welding electrodes or filler rods. Your welds become stronger, cleaner, and easier to finish.

Comparison with Alternatives

Other Coating Materials

There are many choices for welding rod coatings. Each one helps welding in its own way. Here are some common types:

Titanium dioxide makes a slag that is very runny and cools fast. It also helps start the arc.

Cellulose breaks down when hot and makes gases. These gases protect the weld from air.

Metal carbonates change the slag’s pH and help make a safe area for welding.

Calcium fluoride makes gases that shield the weld and also changes the slag’s pH.

Each material does something different in welding. Some help keep air away, and others change how the slag acts. But none can control how runny the slag is or keep the arc steady like manganese dioxide.

Unique Advantages

Manganese dioxide is special in welding rod coatings. It gives you some benefits that other materials do not.

It makes the slag easy to take off after welding.

It keeps the arc steady, so your welds are cleaner and stronger.

It helps the slag form right and protects the weld pool.

Coating Material | Main Function in Welding | Unique Benefit |

|---|---|---|

Manganese dioxide | Controls slag, stabilizes arc | Manages slag fluidity |

Titanium dioxide | Fluid slag, arc ionization | Quick-freezing slag |

Cellulose | Gas shielding | Gaseous protection |

Metal carbonates | Adjusts slag pH, reducing effect | Slag chemistry control |

Calcium fluoride | Shielding gases, pH adjustment | Extra protection |

Note: You pick manganese dioxide when you want the best control of slag and arc steadiness. This is why it is important for many welding jobs.

You can tell that manganese dioxide welding rods help make welding safer. These rods help you get a steady arc. They also give strong slag protection. Your welds look cleaner and have fewer problems. When you pick the right coating, your welds get better.

Welding rod coatings keep the weld zone safe and make it stronger.

If you match the rod coating to your metal, you stop cracks and holes.

Storing rods the right way keeps the coating working well.

Picking the best welding rod coating helps you get welds that last longer and stay clean.

FAQ

What does manganese dioxide do in welding rod coatings?

You get a stable arc and strong slag when you use manganese dioxide. It helps your weld stay clean and tough.

Tip: Manganese dioxide also protects your weld from rust and moisture.

Can you use manganese dioxide welding rods for all metals?

You can use these rods for many metals. They work best with steel and iron. You should check your metal type before welding.

Is slag removal easier with manganese dioxide welding rods?

Yes, you can remove slag more easily. The slag forms a smooth layer. You spend less time cleaning your welds.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.