Manganese dioxide recycling is very important for battery waste management. By 2060, the world could have 46 million tons of battery waste. But recycling only meets a small part of what is needed. Good recycling helps stop pollution. It saves resources. It also helps make battery production more sustainable.

| Metric | Value / Description |

|---|---|

| Total global waste batteries by 2060 | 46 million tons |

| Share recycled by 2060 | 43% |

| Supply from recycled manganese (2020) | 1.3% of demand |

- Recycling manganese dioxide from batteries helps cut down pollution. It saves natural resources. It supports cleaner energy by using old materials again. This means we do not need to mine new ones.

- Using recycled manganese dioxide makes batteries cheaper to produce. It helps battery makers follow environmental rules. It also adds economic value. This supports a circular economy.

- Better recycling technology will make battery waste management safer. Building more recycling centers around the world will help. This will make recycling faster and better for the planet.

Sustainability of Manganese Dioxide Recycling

Manganese dioxide recycling is a good way to manage battery waste. This process helps protect the environment. It saves resources and is good for the economy. Recycling gets useful materials from old batteries. This means less mining is needed. It helps make a system where battery materials are reused. Recycling old batteries also cuts down on pollution. It supports goals for a cleaner and safer world.

Environmental Impact

Manganese dioxide recycling helps the environment in many ways. It lowers the harm caused by battery waste. This happens because it stops toxic metals from getting into air, water, and soil. Recycling keeps dangerous stuff out of landfills and nature. It also reduces greenhouse gases compared to throwing batteries away.

Scientists found that manganese dioxide from old batteries can be used in microbial fuel cells to make electricity. These cells made up to 757 mW/m³ of power. That is three times more than platinum cathodes. This shows recycled manganese dioxide can help with clean energy and battery recycling.

Recycling can also cause some pollution. Some methods use chemicals like selenium dioxide. This can mean more water is used and more solid waste is made. Using high-grade manganese ores makes less solid waste. Places that recycle selenium-contaminated manganese alloys have problems with dangerous waste. Dust from rotary furnaces is hard to manage. The metals industry, including manganese processing, still puts metal toxins in the air. Some countries have less pollution now because they use energy better. But checking and reporting pollution still needs work. Tests and monitoring are needed to make sure pollution goes down and controls work.

Manganese dioxide recycling also helps lower greenhouse gases and toxic waste. When mixed with biochar in composting, manganese dioxide can cut ammonia gases by 58.9%. This means less nitrogen gas and better compost. These changes make battery recycling better at stopping pollution than old ways of disposal.

Economic Benefits

Manganese dioxide recycling is good for battery makers and recyclers. Getting manganese and other important minerals from old batteries saves money. It also helps with clean development. Recycling old batteries in NMC types adds social and environmental value. This value can be between $11.3 billion and $40.3 billion in different markets.

- Recycling gives more profit than mining, especially when thinking about people and the planet.

- The Inflation Reduction Act gives tax credits up to $3,750 for each battery. This makes recycled materials worth more for companies.

- Recycling lowers costs for following environmental rules. It also helps meet rules for using local materials.

| Economic Benefit Aspect | Description |

|---|---|

| Cost savings from recycled cathode materials | Using recycled cathode materials, like manganese in NMC batteries, can save up to 40% compared to new materials. |

| Cost reduction per kg | Recycling can lower production costs by about $1.87 per kg compared to new materials. |

| Green resource supply | Recycling gives a cheaper and cleaner option for metals like cobalt and nickel. This helps manganese use too. |

| Collection rate limitation | Even with savings, only a small number of used batteries are recycled now. This limits how much money can be saved. |

Recycling old batteries helps keep useful materials in use. It means less need for new mining. This helps manage resources in a smart way. It supports long-term goals for clean development. As recycling gets better and more batteries are collected, the good effects of manganese dioxide recycling will grow.

Role in Battery Waste Management

Pollution Prevention

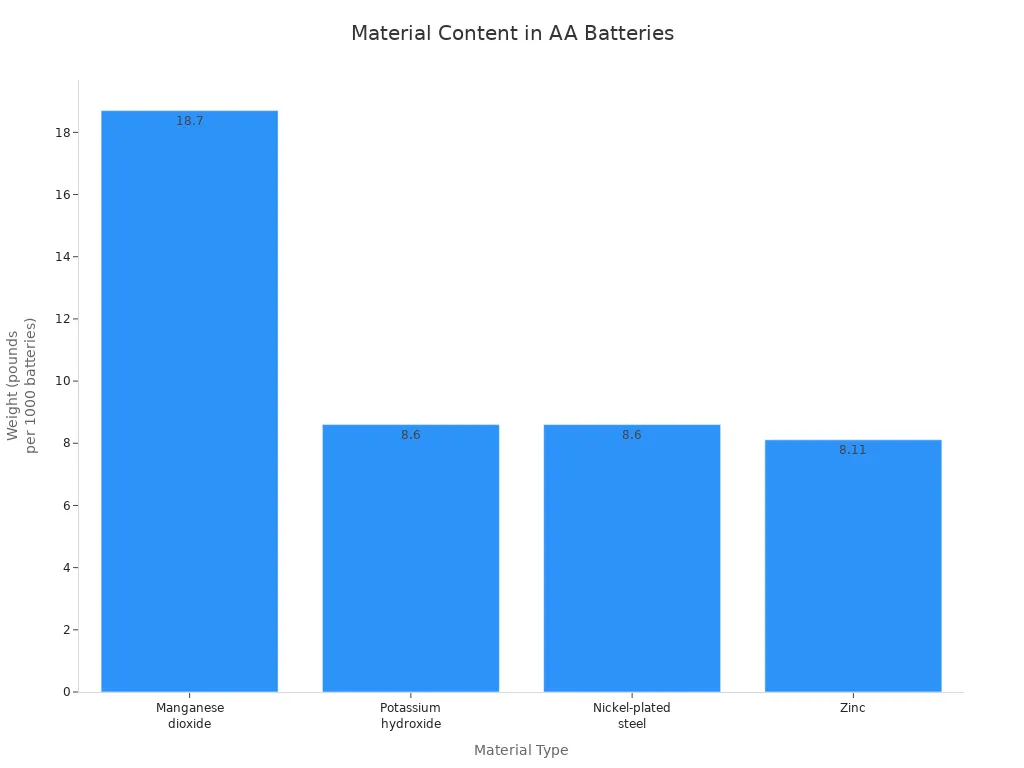

Manganese dioxide recycling helps stop pollution from battery waste. When companies recycle old batteries, they keep toxic chemicals out of nature. AA batteries have manganese dioxide, potassium hydroxide, nickel-plated steel, and zinc. Recycling makes sure these materials do not harm the environment.

Material in AA Battery (per 1000 batteries) | Approximate Weight |

|---|---|

Manganese dioxide | |

Potassium hydroxide | 8.6 pounds |

Nickel-plated steel | 8.6 pounds |

Zinc | 8.11 pounds |

Recycling old batteries saves metals and stops dangerous stuff from going to landfills. New recycling methods can get more than 99% of manganese and zinc fast. These ways also give very pure materials. This means less risk of pollution and a cleaner world. Companies use closed-loop recycling to stop extra pollution and cut down on waste.

Resource Recovery

Recycling waste batteries helps make new products by getting important materials back. Industries use manganese, lithium, cobalt, and nickel again in new batteries and other things. This way saves resources and means less mining. Used batteries can be used again for energy in homes and cars.

Recycling old batteries lowers greenhouse gases and saves energy.

Circular recycling uses less water and stops liquid waste.

Factories use recycled materials to keep costs low and supplies steady.

Almost every part of rechargeable batteries, even plastic, can be reused, so there is less plastic pollution.

Good battery waste management makes sure recycling helps circular manufacturing. This lowers harm to the environment and helps companies reach sustainability goals.

Battery Types with Manganese Dioxide

Alkaline Batteries

Alkaline batteries have manganese dioxide in their cathodes. People use these batteries in many home devices. The manganese dioxide can be α-MnO2, β-MnO2, or γ-MnO2. When companies recycle these batteries, they use heat and leaching to get manganese compounds. This process can get up to 98% leaching and 99% manganese dioxide. The recycled manganese dioxide has mixed phases. It works well in new rechargeable batteries. Recycling helps the circular economy and cuts down on dangerous battery waste.

Aspect | Details |

|---|---|

Composition of Mn | Mainly Mn(III) compounds and MnO2 (α, β, γ phases) |

Heat Treatment | Heated under N2 at 650–950 °C; at 950 °C, forms crystalline MnO only |

Leaching Process | 2 M H2SO4 + 20% excess, 98% leaching efficiency |

MnO2 Precipitation | MnSO4 + KMnO4 at 60 °C, 99% MnO2 yield |

Electrochemical Performance | Recycled MnO2 matches commercial MnO2 in rechargeable batteries |

Environmental Impact | Reduces hazardous waste and supports circular economy |

Note: Using recycled manganese dioxide from alkaline batteries helps make new rechargeable batteries that work well.

Lithium-Manganese Batteries

Lithium-manganese batteries use manganese in their cathodes. These batteries can be recharged and power many things, like electric cars. When recycling lithium-ion batteries, companies get manganese from battery powder. They change the pH to make manganese hydroxide. Then, they use acid leaching to recover about 99.77% manganese. Purification takes out cobalt and nickel. The end product is battery-grade manganese sulfate for new rechargeable batteries.

Manganese recovery uses pH changes and acid leaching.

Purification removes metals that are not wanted.

The process gives very pure manganese for new batteries.

This way helps recycle lithium-ion batteries and means less new mining.

These recycling steps keep important materials in use. They also help more rechargeable batteries get made around the world.

Manganese Dioxide Recycling Methods

There are different ways to recycle spent batteries and get manganese dioxide back. Each method helps battery recycling in its own way. These methods also help with battery-to-battery recycling.

Mechanical

Mechanical recycling uses machines to break batteries apart. Workers shred, crush, and sort the battery pieces. This helps them get metals and non-metals out. The batteries are then ready for more recycling steps. No chemicals are used in this method, so it is safer for the environment. Mechanical recycling makes battery recycling work better and cost less.

Pyrometallurgical

Pyrometallurgical recycling uses very high heat to get metals from batteries. Smelters melt the battery parts. This separates manganese, nickel, cobalt, and copper. This method works well for many battery types. But it uses a lot of energy and makes pollution. The table below shows what is good and bad about this method:

Aspect | Advantages | Limitations |

|---|---|---|

Metal recovery | Works well for Ni, Co, Cu, Fe, Mn | Hard to get lithium |

Technical maturity | Old and simple process | Uses lots of energy, pollutes air |

Feedstock flexibility | Handles many battery types | Does not work well for plastics, graphite, aluminum |

Waste generation | Makes little liquid waste | Makes CO2 and slag that are hard to get rid of |

Economic feasibility | Good for big recycling jobs | Needs enough metal, especially cobalt |

New ways like oxygen-free roasting and molten salt roasting use less energy. They also help get more metals back.

Hydrometallurgical

Hydrometallurgical recycling uses water-based liquids to get metals out of batteries. Workers dissolve manganese and other metals in these liquids. Then they clean and collect the metals. This method gives very pure manganese dioxide for new batteries. It is good for recycling lithium-ion batteries and makes less solid waste. This helps make battery recycling better for the planet.

Biotechnological

Biotechnological recycling uses tiny living things and green liquids to get metals from battery waste. Scientists use microbes and special green solvents to pull out manganese and other metals. These new ideas are still being tested. But they could make recycling work better and be more earth-friendly.

New ways to upgrade EMD use heat and chemicals to make recycled electrolytic manganese dioxide better. The new EMD can hold 20% more charge and can be recharged more times. Using robots and smart computers also helps make recycling faster and the product better.

Sustainability Challenges

Economic Barriers

Recycling old batteries has big money problems. Manganese prices go up and down a lot. This makes it hard for companies to plan and make money. Market needs, supply chain problems, and world issues change prices fast. Companies must change their plans often because of this. The manganese ore business also has mining problems and supply stops from bad weather or worker strikes. These things make it hard for factories to know what will happen. Long-term deals are tough to make. Companies need to find ways to handle these risks so recycling can keep going.

Environmental Risks

Recycling old batteries can help the planet, but it has dangers too. Some recycling uses chemicals that can hurt water or dirt if not handled right. In some countries, recycling is done without safety rules. This can let heavy metals leak out and make workers and people sick. Every year, taking apart batteries without rules lets out thousands of tons of toxic metals. We need better checks and safer ways to recycle to stop these problems.

Infrastructure Gaps

Many places do not have enough centers to recycle old batteries well. Latin America, Africa, and parts of Asia have few recycling centers and weak rules. In these places, most old batteries are recycled in unsafe ways. This makes more danger for people and nature. The table below shows some main problems with recycling centers:

Infrastructure Gap Aspect | Description / Data |

|---|---|

Recycling facility coverage | Developed countries: ~12 per 100,000 sq km; global coverage <30% |

Emerging market coverage | Africa, Southeast Asia: ~3% |

Informal recycling rate | 58% of spent batteries recycled informally in developing countries |

Heavy metal leakage | ~45,000 tons leaked annually from unregulated dismantling |

Countries need more recycling centers, better rules, and stronger supply chains to make recycling work better.

Future of Battery Recycling

Technological Innovation

New technology is changing battery recycling. Better hydrometallurgical and pyrometallurgical methods now recover over 95% of manganese. These methods also lower costs by up to 30%. Smart sorting and machines that take batteries apart make recycling faster. They also help companies follow strict rules. Digital material passports and AI tools help track materials and keep them pure. Small recycling units near waste sites mean less transport and less harm to the environment. Real-time analytics help check quality and make sure companies follow the law. New business ideas, like Battery-as-a-Service, need smart ways to check and track materials. All these changes help make recycling better for the planet and more efficient.

Rules in the U.S., Europe, and Asia make companies use these new ideas for safer and better rechargeable batteries.

Circular Economy

The circular economy is shaping battery recycling’s future. Green chemistry gets pure metals like manganese, lithium, and cobalt. This helps the environment and saves money. Good hydrometallurgical methods use gentle acids and get high leaching rates. They recover manganese and other metals with less waste. These green ways are faster and make recycling more earth-friendly. The circular model also supports rules that make companies collect and recycle old batteries. This stops dangerous piles of waste. In some places, electric car makers must set up recycling and tracking systems. This makes sure rechargeable batteries are managed well and helps the planet. The circular model keeps important materials in use and helps make the world cleaner.

The circular economy gets battery makers to design batteries that are easy to recycle.

It helps companies use recycled materials in new rechargeable batteries.

Circular ideas help cut down on waste and save natural resources.

Manganese dioxide recycling helps keep the planet healthy. It cuts down on waste and saves important resources. Good plans include making companies take care of battery waste. The government checks recycling and teaches people about it. The White House wants rules to help recycling in the U.S. They also want to keep important minerals safe. New ideas, strong rules, and teaching people will help recycling get better in the future.

People learn about recycling.

Scientists study green technology.

FAQ

What is the main benefit of recycling manganese dioxide from batteries?

Recycling manganese dioxide means less new mining is needed. It helps keep nature safe. It also supports better ways to get rid of battery waste.

Can all types of batteries with manganese dioxide be recycled?

Most batteries with manganese dioxide can be recycled. Special places take out useful materials. They help make battery waste disposal safer.

How does manganese dioxide recycling support a circular economy?

Manganese dioxide recycling keeps materials being used again. It cuts down on waste. It helps make battery waste disposal work in a circle.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.