Manganese dioxide magnetic properties are important in today’s technology. Different MnO2 polymorphs act in special ways. These ways change how they work in batteries, supercapacitors, and electromagnetic shielding. Scientists use these differences to make charge storage better. They also help increase energy density and absorb electromagnetic waves in many new devices.

Manganese dioxide acts differently with magnets. Its behavior changes with crystal form and temperature. Scientists use this to make batteries better. They also use it for catalysts and medical tools.

Changing the size and shape of manganese dioxide nanostructures helps engineers. They can control its magnetic properties. This makes energy storage better. It helps chemical processes stay cleaner. It also makes medical imaging safer.

Research and new technology keep improving manganese dioxide materials. The goal is to make them smarter and greener. They want these materials to work better for future healthcare and energy needs.

Manganese dioxide magnetic properties

Polymorphs and magnetism

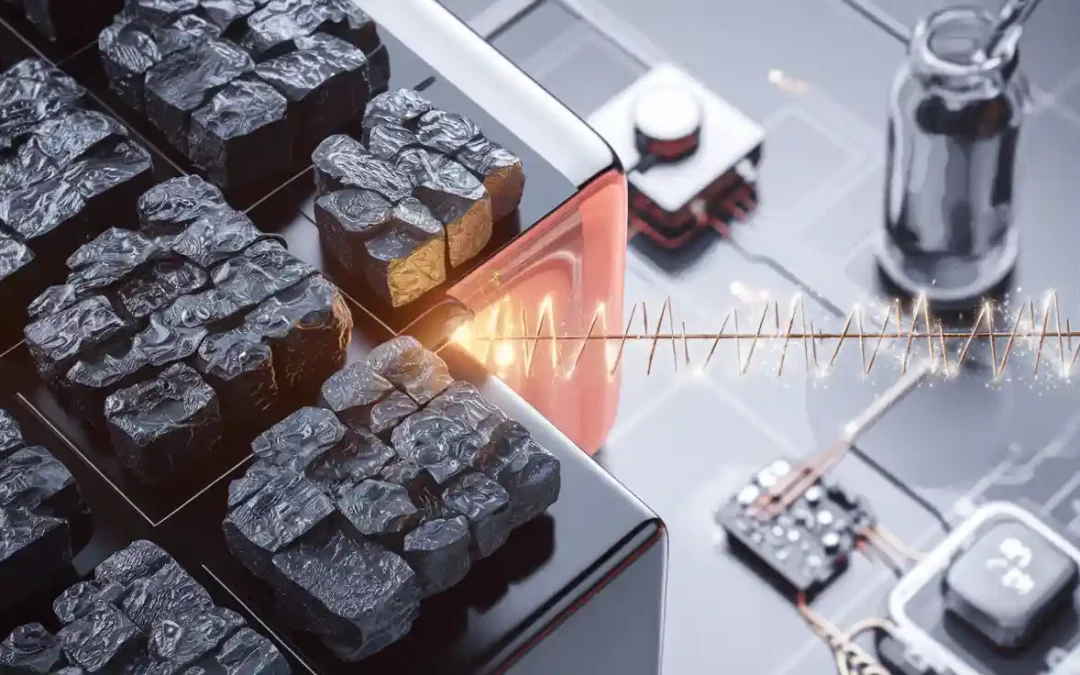

Scientists learn about manganese dioxide magnetic properties by studying its different polymorphs. Each polymorph has its own crystal structure. This makes them act differently with magnets. There are three main types: β-MnO2, δ-MnO2, and γ-MnO2. They each have special magnetic transitions and magnetization levels. The table below shows how they are different:

Polymorph | Magnetic Transition Temperature | Magnetic Behavior | Magnetization Level | Influencing Factors |

|---|---|---|---|---|

β-MnO2 | 92 K | Paramagnetic to antiferromagnetic | Lowest | Intrinsic magnetic ordering |

δ-MnO2 | 20 K | Paramagnetic to antiferromagnetic | Highest | Impurity ions/molecules and vacancies |

γ-MnO2 | No transition observed | Remains paramagnetic | N/A | N/A |

Temperature is very important for manganese dioxide magnetic properties. For example, α-MnO2 nanorods change their magnetism when the temperature changes. At cold temperatures, they show two magnetic transitions. Smaller nanorods have lower Néel temperatures. When α-MnO2 gets very hot, it can turn into cubic Mn2O3. This shows that heat can also change the structure.

Other polymorphs, like γ-MnO2 and ε-MnO2, have ferromagnetic spin ordering at different Curie temperatures. γ-MnO2 is more stable than ε-MnO2 when heated. It turns into β-MnO2 if the temperature goes above 150 °C. These changes mean manganese dioxide magnetic properties depend on the polymorph and the temperature.

Nanostructures and morphology

The shape and size of manganese dioxide nanostructures, like nanorods and nanoparticles, affect their magnetic properties a lot. Scientists found that α-MnO2 nanorods can act like spin-glass materials below 50 K. β-MnO2 nanorods show antiferromagnetic transitions near 92 K. The tunnel size and the ions inside, such as potassium, can change the magnetic order. If more potassium ions fill the tunnels, the nanorods can switch between ferromagnetic and antiferromagnetic behavior.

Tip: Changing the shape of manganese dioxide nanostructures lets scientists control their magnetic properties for different uses.

Morphology also changes the ratio of Mn3+ to Mn4+ ions. This affects how the material acts with magnets. Nanorods with different crystal planes show special magnetic features. For example, α-MnO2 nanowires with (1 1 0) planes are ferromagnetic. Those with (2 1 0) planes are mostly antiferromagnetic but have strong exchange bias effects. This means engineers can design materials with certain manganese dioxide magnetic properties for batteries, photocatalysis, and magnetic nanodevices.

Studies on manganese silicide nanostructures show that size and shape matter. Nanorods and nanoparticles can be ferromagnetic at room temperature because of their special shapes. High magneto-crystalline anisotropy in these shapes makes them good for new technologies.

By changing the nanostructure morphology, scientists can tune manganese dioxide magnetic properties. Engineers can make materials with better energy storage, stronger catalytic activity, and new magnetic uses by controlling the size, shape, and crystal planes of manganese dioxide nanostructures.

Magnetic basis

Magnetic ordering

Magnetic ordering in manganese dioxide depends on how manganese atoms connect. In α-MnO2, manganese atoms are inside MnO6 octahedra. These octahedra join at corners and edges to make tunnels. How the atoms join decides if it is antiferromagnetic or ferromagnetic. Antiferromagnetic coupling happens in corner-sharing octahedra. Ferromagnetic coupling happens in edge-sharing octahedra. When scientists add potassium ions to the tunnels, the crystal structure changes. A small amount of potassium makes the lattice bend and moves charges. This can upset the balance and cause ferromagnetic-like ordering at cold temperatures. More potassium fills the tunnels evenly and brings back antiferromagnetic behavior. The crystal order and how much doping there is control the magnetic properties.

Note: Doping and defects in the crystal can change the magnetic behavior from antiferromagnetic to ferromagnetic.

Exchange interactions

Exchange interactions decide the magnetic properties of MnO2. In α-MnO2 nanowires, Mn4+ ions interact through oxygen atoms. This makes antiferromagnetic superexchange, which is the main magnetic part. Sometimes, Mn3+ ions show up and make ferromagnetic clusters, but these are weak. At the surface, some Mn4+ ions do not pair up. These unpaired spins make net magnetic moments and spin glass behavior. Surface spins interact with the antiferromagnetic inside, causing exchange bias effects. The splitting of Mn 3d orbitals in the octahedral field keeps magnetic moments steady. All these bulk and surface exchange interactions explain why MnO2 nanostructures show antiferromagnetism, ferromagnetic clusters, spin glass behavior, and exchange bias.

Key points:

Bulk interactions cause antiferromagnetism.

Surface effects make spin glass and exchange bias.

Doping and defects change the balance between these behaviors.

Applications

Medical uses

Manganese dioxide is important in medical imaging. Scientists use MnO2 nanoparticles in MRI scans. These nanoparticles have Mn2+ ions, which are paramagnetic. This helps make T1-weighted MRI images brighter and clearer. Doctors can see organs and tissues better. MnO2 nanoparticles are stable and work well in the body. They are less toxic than gadolinium-based agents. Manganese is already found in cells, so it is safer for patients. These nanoparticles can target certain cells by moving through calcium channels. This helps doctors find diseases more easily. Some MnO2 nanoparticles help with both imaging and therapy. For example, they can guide cancer surgery and improve ultrasound treatment. These features make manganese dioxide useful for safer and better MRI scans.

Catalysis and batteries

Manganese dioxide magnetic properties help in catalysis and batteries. In catalysis, MnO2 is a strong catalyst for oxidation reactions. Scientists put MnO2 on magnetic supports like Fe3O4 nanoparticles. This gives more surface area and better redox activity. The magnetic property lets people separate the catalyst with a magnet. This saves time and cuts down on waste. The catalyst can be used again and again, so it saves money and helps the environment. MnO2-based catalysts are used to make chemicals, clean water, and produce medicines.

In batteries, MnO2 is used as a cathode, especially in lithium-ion batteries. The delta phase (δ-MnO2) has a layered structure. This lets lithium ions move in and out easily when charging and discharging. The flower-like shape of δ-MnO2 helps the battery work better at high speeds. It also helps the battery last longer by stopping damage. MnO2 is cheap and safe, so it is good for storing energy. The magnetic properties do not directly change how batteries work. But changing the structure and makeup of MnO2 can make batteries better.

Tip: Magnetic catalysts help make chemical processes cleaner and greener because they are easy to recover and reuse.

Industrial processes

Many factories use manganese dioxide magnetic properties in their work. Magnetic MnO2-based catalysts help in making chemicals, like in oxidation and coupling reactions. The magnetic property lets workers pull out the catalyst with a magnet. This makes it easy to recycle and lowers costs. The catalyst stays strong and works well for many uses. It also means fewer dangerous chemicals and less energy are needed. These things help green chemistry and make factories safer and more efficient. Companies use these catalysts for big jobs, like cleaning water and making medicines.

Key advantages of magnetic MnO2 catalysts in industry:

Easy to separate and recycle

Very stable and active

Saves money

Helps make processes eco-friendly and sustainable

Challenges

Toxicity

Manganese dioxide is safe for the body and not very toxic. This makes it useful in medicine. Scientists use MnO2 nanoparticles to find tumors and deliver medicine. They also use them for treatments. These nanoparticles stay stable in the body, especially with a PEG coating. PEG helps them last longer and makes them smaller. The nanoparticles react with things like glutathione in the body. They help kill cancer cells but do not hurt healthy cells much. Most tests show MnO2 does not harm organs. It leaves the body through the liver and kidneys. But scientists still check if it is safe for a long time.

MnO2 nanoparticles spread well in the body.

They can carry medicine and react with body molecules.

Most tests show they are safe for tissues.

More research is needed to know if they are safe long-term.

Stability

Stability is still a problem for manganese dioxide in technology. In batteries, MnO2 cathodes can break down and stop working well. They can also get bigger and lose power fast. Scientists try to fix this by adding nitrogen or sulfur. They also mix MnO2 with other materials. In catalysis, MnO2 can change or fall apart in water or heat. Using strong supports helps MnO2 last longer. These ideas help MnO2 work better in real devices.

Economic factors

Region | Market Size (2024, USD Million) | Key Drivers |

|---|---|---|

Asia Pacific | N/A | Fast growth, battery demand, urbanization |

North America | Battery use, strong industry, regulations | |

United States | 7.42 | Battery production, water treatment, electronics |

Europe | 7.05 | Batteries, ceramics, water treatment, rise of EVs, environmental rules |

Many money issues affect manganese dioxide use. There is not much high-grade ore, and mining rules make it cost more. People like synthetic MnO2 because it is pure, but it is expensive to make. Making it needs costly machines and steady supplies. Batteries and electronics need a lot of MnO2, but problems in the supply chain and the environment can slow things down. Companies must think about cost, supply, and rules to use MnO2 everywhere.

Future directions

Emerging research

Researchers are finding new ways to control manganese dioxide magnetic properties. Many teams work together from different science fields. They use nanotechnology, chemistry, and materials science. Some also use biomedical engineering. This teamwork helps them change the size and shape of MnO2 nanoparticles. They also change the surface of these particles. Scientists use chemical methods like solvent exchange and one-step reduction. These methods help make MnO2 nanoparticles. They also change the surface to help them mix with water. This makes the particles safer for the body. These changes are important for medical uses like MRI scans.

Scientists often mix MnO2 with other materials. For example, they add liposomes or plasmonic nanoparticles. This makes new tools for imaging and therapy. Researchers also want MnO2 to be safer in the body. They study how the body breaks down and removes these particles. This helps make MnO2 better for long-term medical use.

Note: When scientists from different fields work together, they can design MnO2 materials with special magnetic properties for many uses.

Technology trends

New technology trends are changing how manganese dioxide is used. Many researchers want MnO2-based materials to be smarter and work better. Some important trends are:

Multifunctional nanomaterials: Scientists make MnO2 particles that can do more than one job, like imaging and drug delivery.

Green synthesis methods: Teams find ways to make MnO2 that are better for the environment and use less energy.

Advanced energy storage: Engineers make MnO2 better for batteries and supercapacitors, so they last longer and hold more energy.

Personalized medicine: Researchers make MnO2 nanoparticles that go to certain cells or tissues, making treatments safer and work better.

These trends show that manganese dioxide will be important in future technology and healthcare.

Manganese dioxide magnetic properties are used in lots of technology. But its ability to change in chemistry is very special.

Factories use manganese dioxide for batteries, pigments, and catalysts.

Scientists try new ways to make it and change its tiny shapes to work better.

People are still studying it, so there could be more uses soon. This could make manganese dioxide even more useful later on.

FAQ

What makes manganese dioxide magnetic?

Manganese ions in manganese dioxide have unpaired electrons. These electrons give the material magnetic moments. The way the atoms are arranged and the temperature can change how strong the magnetism is.

Can manganese dioxide be used in medicine?

Doctors use manganese dioxide nanoparticles in MRI scans. These particles help make the pictures brighter and easier to see. They are safer than some other contrast agents.

Why do scientists study different shapes of MnO2?

Shapes like nanorods or nanoparticles change how manganese dioxide works with magnets. Scientists use these shapes to make batteries, catalysts, and medical tools better.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.