Leading manganese dioxide global producers in 2025 are South32, btlnewmaterial (manganesesupply.com), Eramet, and Ningxia Tianyuan Manganese Industry. These companies help the industry grow. They give important materials for batteries and chemicals.

Major regions shape the market with strong production:

South Africa makes about 30% of the world’s output and is number one.

Gabon is important because it has big reserves and new investments.

Australia sends out steady exports and uses advanced mining systems.

Their focus on green technology and steady supply helps new ideas around the world.

South Africa makes the most manganese dioxide in the world. It gives about 30% of all the output. This helps both local and global businesses.

Big companies like South32 and Eramet use green technology. They focus on quality and safe practices. They work to meet the growing need for manganese dioxide.

The manganese dioxide powder market will grow a lot. This is because more batteries are needed for electric cars and clean energy.

Gabon and Australia are also important in this field. They spend money on new technology and better mining. This helps them make more and keep a steady supply.

Producers work together and invest in new projects. This will help the manganese dioxide industry meet the needs of the world.

Manganese Dioxide Global Producers

South32

South32 is one of the top manganese dioxide global producers. The company runs big mining sites in South Africa and Australia. South32 uses new technology to make production better. Their work helps the battery and chemical industries. South32 keeps the market strong by giving steady, high-quality manganese dioxide. The company works to mine manganese in ways that protect the environment.

South32 cares about new ideas and safety. This makes other manganese dioxide global producers want to do better too.

btlnewmaterial (manganesesupply.com)

btlnewmaterial, with its website manganesesupply.com, is important in the global market. The company focuses on mining and processing manganese. btlnewmaterial gives manganese dioxide to battery and chemical companies. Their factories in China use modern machines for good quality. The company works hard to meet the need for manganese dioxide in electric vehicles.

btlnewmaterial helps the market grow by making more manganese mines.

The company’s strong base in China lets it reach many customers.

Eramet

Eramet is also a top manganese dioxide global producer. The company has manganese mining projects in Gabon and other places. Eramet uses special methods to make very pure manganese dioxide. Their products are used in batteries, steel, and chemicals. Eramet can quickly react to changes in what the market needs.

Company | Region | Main Activity | Market Focus |

|---|---|---|---|

Eramet | Gabon, Europe | Manganese Mining | Batteries, Chemicals |

Eramet spends money on research to help grow and make mining better.

Ningxia Tianyuan Manganese Industry

Ningxia Tianyuan Manganese Industry is a leader in manganese mining in China. The company makes a lot of manganese dioxide for the world. Ningxia Tianyuan gives materials to battery and chemical factories. They focus on checking quality to stay ahead of other manganese dioxide global producers. The company uses green ways to help the planet and grow.

Ningxia Tianyuan’s strong spot in China helps it do well in the fast-growing battery market.

Other Key Producers

Many other companies help the manganese mining industry. These producers work in China, South Africa, and Australia. They help fill the rising need for manganese dioxide. Many companies use new technology to make more and help the market grow. All these manganese dioxide global producers work together to keep industries supplied.

Big producers in China keep making more manganese mines.

Companies in South Africa and Australia work on new ideas and care for the environment.

The world market depends on these manganese dioxide global producers to help batteries, chemicals, and other industries grow.

Leading Regions

South Africa

South Africa is the top producer of manganese dioxide in 2025. The country uses advanced mining and cares about quality. South32 runs big mines in South Africa. Sales went up by 48%. Production grew by 25%. This helps local and global industries. Many companies use new technology to work better and help the environment. South Africa has lots of reserves and skilled workers. This keeps it ahead of other places. South Africa’s lead in manganese dioxide affects the world supply chain.

Company | Operation | Sales Performance | Production Performance |

|---|---|---|---|

South32 | South Africa Manganese | 48% increase in sales |

South Africa’s mining keeps getting new investments and ideas. This makes it important in the industry.

Gabon

Gabon is strong in the global manganese dioxide market. The country has lots of minerals and new money for mining. Companies in Gabon care about the planet and make good products. The government helps by bringing in foreign money and new machines. This helps Gabon compete with bigger producers like South Africa. Gabon keeps growing and gives steady supply to battery and chemical makers.

Australia

Australia is a big producer of manganese dioxide. The country uses smart mining and checks quality. GEMCO is the main producer in Australia. GEMCO makes 87% of Australia’s manganese. South32 owns 60% of GEMCO. Anglo American owns 40%. Australia sends out steady exports and likes new ideas. The mining sector works with South Africa and Gabon to help the world supply chain.

GEMCO is the main manganese dioxide producer in Australia.

GEMCO makes 87% of Australia’s manganese.

South32 owns 60% of GEMCO, Anglo American owns 40%.

Region | |

|---|---|

North America | Data not specified |

Europe | Data not specified |

China | Data not specified |

Japan | Data not specified |

Why They Lead

Production Scale

Top companies are leaders because they mine a lot of manganese. They build new factories and open more sites to meet demand. The Electrolytic Manganese Dioxide (EMD) market is growing fast. This is because electric cars and energy storage need more EMD. Companies work on research to make more and do it better. Their big factories help keep minerals available for everyone. This helps the industry grow around the world. Companies in South Africa, Gabon, and Australia use green ways to save resources and cut waste.

Big manganese mining helps batteries and water cleaning. This makes the industry grow.

Technology and Quality

New ideas make top manganese companies stand out. They use special electrode materials like titanium alloy anodes. These have coatings to work better. They use smart machines and AI to control the process. This helps them make good products every time. They add special chemicals to make manganese dioxide work better. Real-time checks let them fix problems fast. New factories use 15% less energy and up to 40% less water. This helps the planet. Companies make sure every batch is 99.9% the same. This makes people trust their products.

Innovation Type | Description | Benefits |

|---|---|---|

Advanced electrode materials | Titanium alloy anodes with coatings | Better efficiency and consistency |

Electrolyte additives | Proprietary formulas | Improved product performance |

Process automation | AI-driven control systems | Higher production efficiency |

Energy efficiency improvements | Improved cell design and power management | Lower energy use |

In-line quality monitoring | Real-time analysis | Immediate process adjustments |

Quality improvements | Higher product quality | |

Environmental impact reduction | Water use cut by 30-40% | Lower environmental footprint |

Supply Chain Integration

Top manganese companies build strong supply chains to stay ahead. They control the ore and run their own plants. They make special grades for different jobs. They care about green mining and try to make less waste. They spend money on research to find new uses for manganese. They work with other companies to deliver products on time. They also sell in new places to grow bigger and stronger.

Strategy | Description |

|---|---|

Vertical Integration | Control over ore supply and processing facilities |

Product Differentiation | Specialized grades for industry needs |

Focus on Sustainability | Green mining practices and waste reduction |

Investment in R&D | Improved processes and new applications |

Strategic Partnerships | Collaboration with downstream companies |

Market Expansion | Entry into new regions for greater market reach |

Good supply chains help companies give the world steady and green manganese mining products.

Company Comparison

Capacity and Output

Top manganese mining companies are not all the same. Some have big operations and make a lot of product. Others make special products for certain uses. The table below shows how much they can make and earn from 2020 to 2025. Many companies do not share their exact numbers. Still, these companies are important in manganese mining.

Company Name | Production Capacity (2020-2025) | Production Value (2020-2025) | Gross Margin (2020-2025) |

|---|---|---|---|

Tosoh | N/A | N/A | N/A |

ERACHEM Comilog | N/A | N/A | N/A |

Tronox Limited | N/A | N/A | N/A |

Cegasa | N/A | N/A | N/A |

Mesa Minerals Limited | N/A | N/A | N/A |

Golden Mile GmbH | N/A | N/A | N/A |

Moil | N/A | N/A | N/A |

Vale | N/A | N/A | N/A |

Manmohan Minerals and Chemicals | N/A | N/A | N/A |

MnChemical Georgia | N/A | N/A | N/A |

Bigger manganese mining companies can give more to the world. They help battery and chemical industries grow.

Geographic Reach

Top manganese mining companies work in many places. North America and Europe have steady markets. Companies there meet regular needs for manganese dioxide. Asia-Pacific is growing fast with new factories and projects. Latin America, the Middle East, and Africa are new areas with chances to grow. Companies build roads and use new machines to reach these places. Working in many regions helps companies keep up with changes and stay strong in manganese mining.

North America and Europe: Steady need and good supply chains.

Asia-Pacific: Fast growth and new mining projects.

Latin America, Middle East, Africa: New markets with more chances.

Market Influence

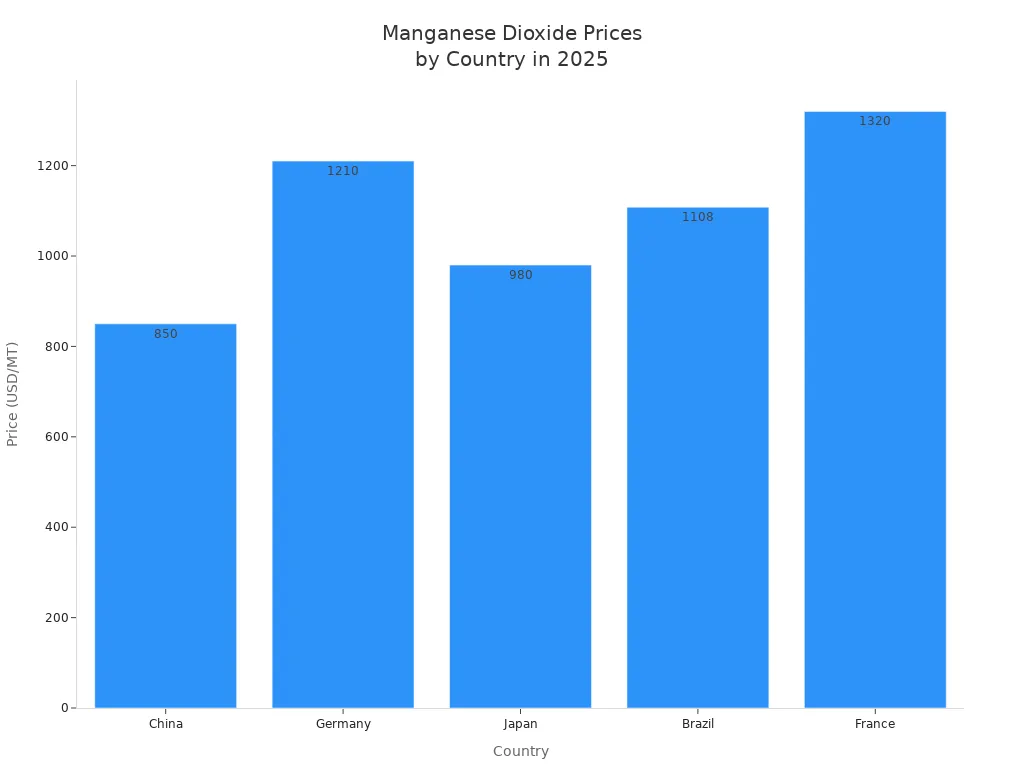

Manganese mining companies help set prices and trends around the world. How much they make and sell changes prices in each country. The table below shows manganese dioxide prices in 2025 for different places. Things like how much is stored, steel making, and imports change the prices.

Country | Price (USD/MT) | Influencing Factors |

|---|---|---|

China | 850 | High inventory levels, fluctuating steel production, stable ore imports from Africa |

Germany | 1,210 | Stable demand from automotive and steel sectors, global oversupply |

Japan | 980 | Consistent demand from specialty steel producers and battery manufacturers |

Brazil | 1,108 | Ample domestic production, subdued export demand |

France | 1,320 | Demand from steel sector, imports from Africa and South America |

Top manganese mining companies lead by choosing how much to make, using new machines, and moving into new places. Their choices change prices and how much is available for many industries.

Manganese Dioxide Powder Market

Market Size

The manganese dioxide powder market was worth about USD 1.5 billion in 2025. Experts think the market will grow by 9.7% each year until 2031. This is because batteries and green energy storage need more powder. Many industries depend on manganese mining for good powder. The market keeps growing as more companies want green solutions.

Current market value: USD 1.5 billion

Projected annual growth rate: 9.7% (2025-2031)

Main industries: batteries, green energy, chemicals

Demand Drivers

More people want manganese dioxide powder every year. Batteries use this powder for electric cars and green energy storage. Chemical companies need it for ceramics and glass. Green technology makes the market grow even faster. Electric cars use more batteries, so they need more powder. Storage for renewable energy also needs more powder. Companies try to make powder in green ways to keep up with demand.

Batteries, electric cars, and green energy storage make the market grow.

Regional Trends

The manganese dioxide powder market is different in each region. Asia-Pacific uses about 55% of the world’s powder. This is because they make lots of batteries and have big factories. North America is next, with the United States using a lot for storage and batteries. Europe comes after, helped by green rules and goals. Latin America and the Middle East & Africa are growing slowly. New buildings and green projects help them grow.

Region | Market Share (%) | Key Factors |

|---|---|---|

Asia-Pacific | 55 | Manufacturing, batteries |

North America | 25 | Technology, storage |

Europe | 15 | Green policies, demand |

Latin America | 3 | Infrastructure, growth |

Middle East & Africa | 2 | Green investments, growth |

The manganese dioxide powder market keeps getting bigger as people need more green technology and storage around the world.

Industry Trends

Battery Sector Growth

The battery industry is growing fast. Companies pay attention to making batteries. Batteries are used in many things and cars. People want better batteries every year. Experts think batteries will stay important. The new battery industry helps the whole market grow. Battery makers need more manganese dioxide now. Electric cars also make the need for batteries go up. Companies spend money on new ways to make batteries better. Experts believe this part of the market will keep growing.

Batteries are a big part of where the industry is going.

Environmental Factors

Laws about the environment change how companies work. Companies must follow rules to help the earth. More people want green ways to make things. Many companies try new ideas to use less and save energy. Experts say clean ways to make things are needed. Recycling and using less water are important now. The industry tries to hurt nature less. Battery makers show others how to be eco-friendly. Better batteries now use cleaner stuff. People want safe and green batteries more each year.

Future Outlook

The future looks good for the industry. Experts think the market will get bigger as more batteries are needed. Batteries will help the market grow the most. More companies will start working in this field. People will keep wanting better batteries. New ideas and better ways to make things will come. Experts think the market will keep growing for five years. Companies that follow new trends will do well. The industry will keep changing to fit what people need.

The future looks bright because demand and new trends help the industry move forward.

Top manganese dioxide producers in 2025 use new technology and have big operations. They also have strong supply chains. South Africa, Gabon, and Australia are important regions. These places help the world market by making a steady supply and trying new ideas.

Companies keep spending money on new projects. They want to make more manganese dioxide for batteries and electric cars.

The US and Australia are building new refining plants. This helps lower risks in getting supplies.

Projects like South32’s Hermosa and Element 25’s HPMSM plant show more manganese will be made at home.

Working together with other countries and starting new projects in different places, like Euro Manganese in Europe and Firebird Metals in China, could change who leads the industry after 2025.

FAQ

What is manganese dioxide used for in 2025?

Manganese dioxide is important for making batteries. It is used a lot in electric cars. Chemical companies use it for glass and ceramics. It also helps clean water. Its high purity helps with new energy storage and green technology.

Who are the top manganese dioxide producers in 2025?

South32, btlnewmaterial (manganesesupply.com), Eramet, and Ningxia Tianyuan Manganese Industry are the main producers. These companies have big mines and modern plants. They work in South Africa, Gabon, Australia, and China.

Why does battery demand affect manganese dioxide prices?

Battery makers need very pure manganese dioxide for their batteries. When more people buy electric cars, they need more manganese dioxide. This higher demand can make prices go up around the world.

Which regions dominate manganese dioxide production?

South Africa, Gabon, and Australia make most of the world’s manganese dioxide. They have big reserves, skilled workers, and use new mining technology. This helps them stay ahead of others in the industry.

How do producers ensure environmental responsibility?

Top producers use green mining to help the planet. They save water, recycle waste, and check pollution. Many companies follow strict rules to protect people and nature.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.