Stricter manganese dioxide environmental regulations set for 2025 are forcing producers to quickly change their processes. Many companies have to slow down operations and spend more money to comply. These new manganese dioxide environmental regulations prevent them from increasing production without using cleaner machines. Producers must adhere to these regulations, invest in better technology, and prioritize environmental care. This approach helps them maintain sufficient output while meeting higher demand.

New manganese dioxide rules in 2025 say companies must use cleaner machines. They also need to change how they make things to help the environment and follow tough rules.

Better machines and using microbes help companies make less pollution. They also save energy and make better batteries while following the new rules.

Planning early and using computers help companies not get fined. They can also spend less money and keep their supply chains ready for new rules and market changes.

Regulatory Changes in 2025

New Standards Overview

In 2025, new manganese dioxide environmental regulations bring big changes. Producers have to follow new rules that help protect nature and support sustainability. The main updates are:

Companies need to use eco-friendly extraction and processing technology for most new projects.

Rules say companies must carefully manage things like habitat, soil, reclamation, and biodiversity.

Water rules are stricter now. Producers must recycle and clean water better. They also use satellite monitoring systems.

Social responsibility rules ask companies to work with communities, create jobs, teach people, and treat workers fairly.

Digital transparency tools like blockchain help track supply chains. These tools make sure companies follow environmental, ethical, and legal rules.

Advanced technology, such as AI advisory systems and carbon footprint tracking, helps watch and enforce sustainability in production.

These new standards try to lower emissions, handle waste better, and save energy. Producers need to change how they work to follow these environmental rules.

Enforcement and Compliance

Government agencies check if companies follow manganese dioxide environmental regulations. They do inspections and use digital monitoring. Producers must give reports about emissions, waste, and energy use. If companies break the rules, they can get fines, stop production, or lose their licenses. Companies use digital tools to show they follow all environmental rules. These steps help protect nature and local people.

Impact on Manganese Dioxide Production

Process Modifications

Producers must change how they make manganese dioxide. They use biological treatments to help the environment. Microorganisms are important in these new methods. These tiny living things change manganese by reduction and oxidation. This makes manganese less harmful and less likely to pollute water or soil. Studies show that special bacteria can remove bad manganese well. Producers watch pH, oxygen, and cell amounts to get better results. These ways cost less and make less extra pollution. Using microbes helps companies follow rules for batteries and other products. But, cleaning acidic wastewater is still hard. Producers need to keep making these methods better for a cleaner process.

Tip: Producers can improve manganese cleanup by changing how they grow microbes and by checking pH and oxygen often.

Technology Upgrades

Better technology is changing how manganese dioxide is made. Companies buy new electrolysis tools and better electrode materials. These upgrades make the process work faster and make better battery products. Energy systems help use less power and lower carbon output. New designs skip steps like calcination and need less iron cleaning. Producers use new cells to reuse ferrous iron. These changes save power and use fewer chemicals. New ways to handle waste and recycle help the environment more. Companies spend less money and follow tough rules. Better technology also helps make cleaner batteries and supports green production.

Technology Upgrade | Benefit | Environmental Impact |

|---|---|---|

Advanced Electrolysis | Higher efficiency | Lower energy use |

Improved Electrode Materials | Better product quality | Reduced carbon footprint |

Energy Management Systems | Optimized resource use | Minimized emissions |

Waste Recycling Innovations | Less waste | Enhanced sustainability |

Waste and Emissions Control

Producers must follow strict rules for waste and emissions in 2025. They add manganese dioxide to compost to cut nitrous oxide by almost 40%. MnO2 slows down denitrification and helps nitrite reduction, which lowers greenhouse gases. The process changes nitrogen cycling, raising genes for nitrite reduction and lowering those for denitrification. Main nitrogen-fixing bacteria, like Streptomyces and Microbacterium, do well with MnO2. These bacteria make compost better and stop nitrogen loss. MnO2 gives spots for microbes to work, helping meet rules for batteries and production.

Main waste and emissions control steps:

Adding MnO2 to compost

Helping nitrogen-fixing bacteria grow

Boosting microbe activity and humification

Cutting greenhouse gases and nitrogen loss

Producers also use special electrolysis cells with fuel to use up to 18% less energy. Decarbonization costs go down by 3% to 15%, based on plant size. The process makes pure CO2, so no extra capture system is needed. These actions help companies follow rules and make manganese dioxide production cleaner for batteries.

Energy Efficiency and Sustainability

Cleaner Production Methods

Manufacturers are now using cleaner ways to make manganese dioxide. They want to meet strict environmental rules. They use new technology to make manganese dioxide more pure. This also helps lower harm to the environment. Many factories use new ways to get and clean manganese dioxide. These ways make less waste and fewer emissions. Companies use recycled materials to help the planet. This means they do not need as many new resources. More factories use solar and wind power. These changes help companies follow rules and make customers happy. People want products that are better for the earth.

New technology makes manganese dioxide more pure and safer for nature.

New ways to get and clean manganese dioxide make less waste.

Using recycled materials helps the planet.

These steps help companies follow rules and give people what they want.

Selenium-free technology is getting more popular. It is a cleaner choice. Companies use life cycle checks to see how their work affects the environment. These checks help them find ways to do better.

Reducing Environmental Footprint

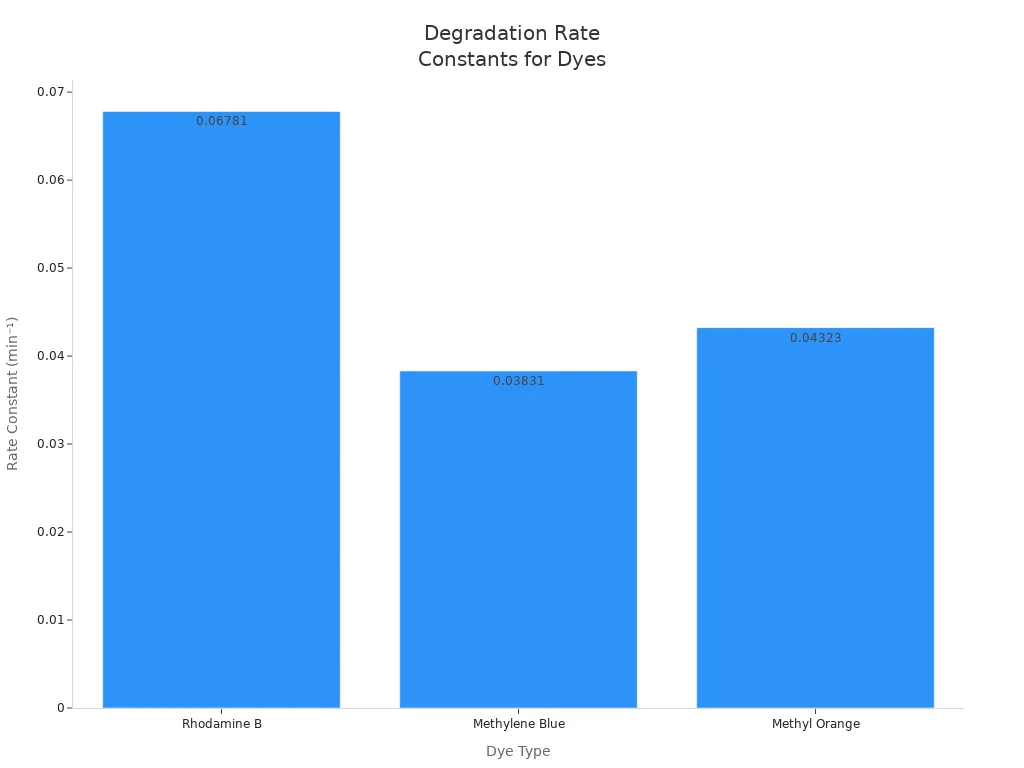

Cleaner ways of making manganese dioxide help the environment. Using microorganisms makes manganese dioxide nanoparticles well. This way is safe and does not hurt nature much. It also kills germs and breaks down dyes fast. This makes it good for the earth. Tests like capacitance and stability show how good the manganese dioxide is.

Cleaner Production Method | Measurable Outcomes / Performance Metrics | Notes / Challenges |

|---|---|---|

Plant Extraction Method | Makes only a little MnO2 nanoparticles | Hard to control; better for nature than old ways |

Microorganism-Based Synthesis | Breaks down dyes fast (up to 92% in 30 min); kills germs well | Needs the right conditions; safety concerns |

Electrochemical Performance Metrics | Shows high capacitance and stability for batteries and supercapacitors | Shows how good the product is |

These better ways help companies care for the earth and make less pollution.

Economic and Supply Chain Effects

Cost Implications

Companies have to spend more money because of new rules. They need to buy better machines and use cleaner technology. These changes help them follow the rules but cost more for research and training. They also pay extra for recycled materials and green energy. Some places have harder rules, so costs go up even more. Small companies feel these costs the most. But if companies make changes early, they can save money later. They avoid fines and work better.

Supply Chain Shifts

In 2025, new rules change how companies handle their supply chains. Some big changes are:

Tougher rules for throwing away heavy metals and recycling batteries.

More companies use green ways, like recycled materials.

Every step, from getting materials to battery disposal, changes.

Companies focus more on safe disposal and recycling.

More people want rechargeable manganese dioxide batteries.

Asia-Pacific is still important but must follow new rules.

More research helps make better batteries and meet the rules.

Note: If companies make their supply chains flexible, they can handle new rules and market changes faster.

Market Stability

Stricter rules help keep the market steady by making companies use safer ways to get and make manganese dioxide. These rules help the industry grow in a green way. Some places, like Mexico, want better mining, so they set higher standards. But in some new markets, hard rules make things cost more and bring problems. The market is moving toward greener ways, but there are still risks. Prices for raw materials can change, and fake options compete. Rules also help new areas grow, like water cleaning, so the market stays steady but keeps changing.

Compliance Strategies for Producers

Best Practices

Producers in the manganese dioxide sector need good compliance strategies to follow new environmental rules. Planning early is very important. Companies that get permits early do not face big delays. This helps them finish projects on time. At the SMEMN Conference, experts said that changing fast when rules change saves money. It also helps companies keep making products without stopping.

Many producers use different ways to treat wastewater. They use chemical precipitation, ion exchange, and biological processes together. These methods help remove bad substances from water. Each site uses the best mix for its needs. This helps companies follow rules and protect the environment for a long time.

Some cities have done well with new water treatment ideas. Farley, Iowa, picked Hydrous Manganese Oxide (HMO) technology for its water plant. This choice made running the plant cheaper and stopped brine waste. Bonne Terre, Missouri, also used HMO technology for its groundwater. The city met rules and cleaned water well.

Tip: Planning early and using the right solutions for each place help producers meet environmental rules.

Tools and Resources

Digital tools are very important for following environmental rules. Producers use monitoring systems to watch emissions and waste all the time. Blockchain technology helps everyone see where materials go and makes sure every step follows the rules. Life cycle assessment tools show companies how their work affects the environment and where they can do better.

Training and workshops teach teams about new environmental rules. Producers also work with technology companies to get better treatment systems. These tools and help let companies follow rules and care for the environment.

Future Outlook for Manganese Dioxide

Environmental Regulations

Regulatory Trends

Manganese dioxide environmental regulations will keep changing after 2025. Governments in Asia Pacific and North America want even tougher rules. These rules will focus on water treatment and how factories work. Companies will have to pay more to follow the rules. They will also get checked more often. Producers must use better monitoring systems and digital tools for reports. Many companies will spend money on new recycling and cleaner technology. They need these to meet future rules. Companies will try to make batteries in a way that is better for the planet. They will also work to make less waste. If producers change fast, they will do better than others.

Note: If companies start using eco-friendly ways early, they can avoid fines and make customers trust them more.

Long-Term Industry Impact

New rules will change the manganese dioxide industry for a long time. Companies will have to spend more money, but they can also find new chances to grow. The table below shows how these changes affect the industry:

Aspect | Impact |

|---|---|

It costs more to follow rules, so battery prices may go up. | |

Growth slows if costs are not managed, but green batteries bring in more buyers. | |

Sustainability & ESG | Eco-friendly batteries and new ideas make new markets. |

Innovation Opportunities | Recycling and green ways help make better batteries and new business. |

Regional Trends | Asia Pacific and North America lead in making green batteries. |

Challenges | Prices can change a lot, and supply chain problems can hurt battery makers. |

Companies must keep watching for new rules and change how they work. Those who make cleaner batteries and try new ideas will do well as things change.

Manganese dioxide environmental regulations in 2025 make producers act quickly. Companies need to use cleaner machines and spend money on research. They also have to make their supply chains strong.

Work on making products in ways that save money and help the planet

Use robots and green machines

Team up with others to make supply chains better

Changing early and always trying to get better helps companies keep up and follow new rules.

FAQ

What are the main environmental rules for manganese dioxide production in 2025?

Government groups want strict waste control and less pollution. They also want companies to use energy better. Producers need to use new machines and follow new rules for mining and making manganese dioxide.

How do producers reduce costs while meeting new regulations?

They buy better machines and use recycled stuff. They also try to save energy. Planning early and having flexible supply chains help companies spend less and not get fined.

Will manganese mining affect local communities under new regulations?

Companies must talk to local people and give them jobs. They also need to keep nature safe. The new rules make sure people near mines are treated fairly and get help.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.