Executive Summary

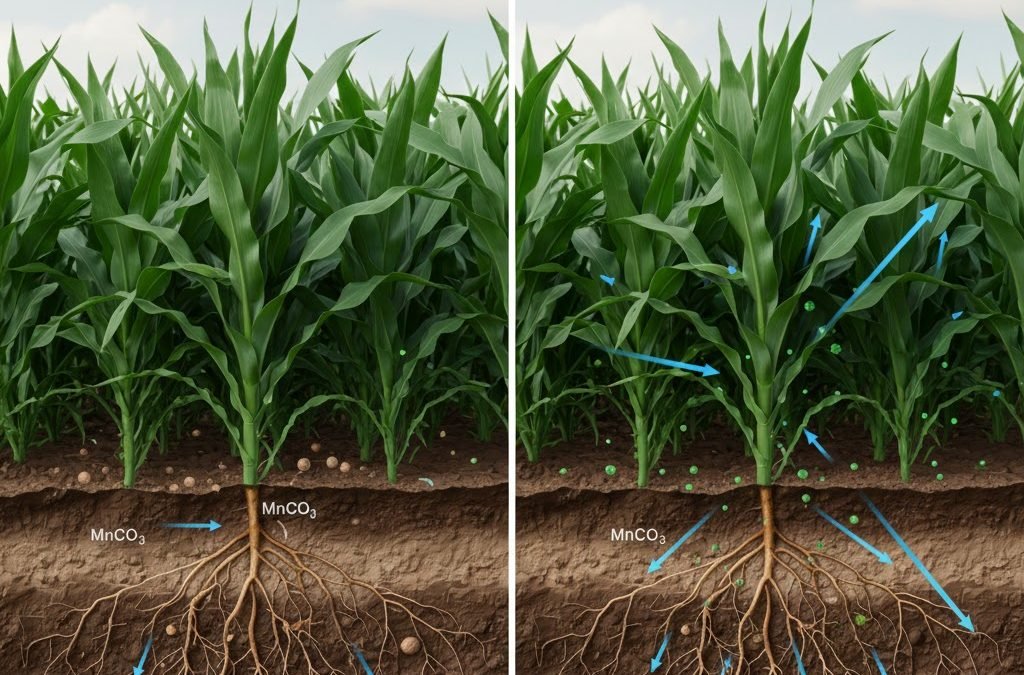

Manganese (Mn) is an essential micronutrient for plant growth, involved in photosynthesis, enzyme activation, and nitrogen metabolism. Two common Mn fertilizers are manganese carbonate (MnCO₃) and manganese sulfate (MnSO₄·H₂O). MnSO₄ generally offers higher water solubility (~33.0 g/100 mL at 20 °C) and a readily plant-available Mn²⁺ form, making it effective for rapid correction of Mn deficiency. Manganese carbonate has lower solubility (<1 g/100 mL) but provides a slow-release Mn source and improves soil pH buffering in alkaline soils.

This article compares both compounds on solubility, agronomic efficiency, soil chemistry interactions, application methods, cost per unit of plant-available Mn, and environmental impact. The key finding: MnSO₄ is better for quick correction and foliar use, while MnCO₃ can be advantageous in high pH soils or sustained supply programs.

1. Technical Background: Why Manganese Matters

1.1 Role of Manganese in Plant Physiology

Manganese is a transition metal micronutrient required in small quantities (typically 20–40 mg kg⁻¹ in leaf tissue) for:

Photosystem II electron transport

Activation of decarboxylases and oxidoreductases

Synthesis of chlorophyll and defense against oxidative stress

Deficiency symptoms include interveinal chlorosis, reduced growth, and poor fruit set, especially in cereals, legumes, and horticultural crops.

1.2 Forms of Manganese Fertilizers

The two focus compounds are:

Manganese sulfate monohydrate (MnSO₄·H₂O): a widely used, water-soluble Mn source.

Manganese carbonate (MnCO₃): less soluble, often considered for slow-release or pH buffering applications.

The choice influences availability in soil solution, reaction with soil minerals, and crop response.

2. Chemical Properties & Soil Interactions

| Property | Manganese Sulfate (MnSO₄·H₂O) | Manganese Carbonate (MnCO₃) |

|---|---|---|

| Mn content (theoretical, %) | ~31.8% Mn | ~38.3% Mn |

| Solubility in water @ 20 °C | ~33 g/100 mL | <1 g/100 mL |

| Primary release form | Mn²⁺ (readily available) | Mn²⁺ (slowly released via dissolution) |

| Soil pH effect | Slight acidifying | Can raise local pH via carbonate reaction |

| Common use | Soil & foliar correction | Soil amendment, slow release |

2.1 Solubility and Uptake

Manganese sulfate dissolves easily in water, quickly increasing Mn²⁺ concentration in the soil solution. This supports rapid root uptake when deficiency is diagnosed late or crops are in critical stages.

Manganese carbonate’s limited solubility makes it less effective for immediate correction but a potential slow-release reservoir, reducing rapid fixation in some soils.

3. Agronomic Performance and Soil Type Considerations

3.1 Acidic Soils (pH < 6.5)

In naturally acidic soils, Mn²⁺ is relatively soluble but can still be tied up by oxides. MnSO₄ usually performs well because:

Its Mn²⁺ is immediately available.

It may slightly lower local pH, enhancing availability.

=> Recommendation: MnSO₄ preferred for acidic soils needing quick response.

3.2 Neutral to Alkaline Soils (pH ≥ 7.0)

At higher pH, Mn²⁺ precipitates as oxides/hydroxides, reducing availability. MnSO₄ still dissolves, but Mn²⁺ can become fixed rapidly.

MnCO₃’s carbonate component reacts with soil:

CO₃²⁻ + H⁺ → HCO₃⁻

This buffers pH locally and may slow release of manganese, but it does not guarantee higher Mn²⁺ availability without acidification.

=> Recommendation: Use MnSO₄ with acidifying amendments (e.g., sulfur or acid-forming fertilizers) for consistent availability. MnCO₃ may supplement but is not a standalone solution in high pH soils.

4. Application Methods & Timing

| Method | MnSO₄ | MnCO₃ |

|---|---|---|

| Soil broadcast | Good | Moderate |

| In-furrow / banding | Excellent | Moderate |

| Foliar spray | Excellent (aqueous soluble) | Not recommended |

| Slow-release programs | Moderate | Potential benefit |

4.1 Soil Application

MnSO₄: Apply at planting or early vegetative stage when deficiency symptoms first appear.

MnCO₃: Best applied before planting and incorporated to increase soil contact for gradual dissolution.

Example agronomic rates (field crops):

MnSO₄: 3–6 kg Mn per ha (as MnSO₄) depending on deficiency severity.

MnCO₃: 5–12 kg Mn per ha in slow-release programs (based on soil test and crop uptake).

4.2 Foliar Use

Only MnSO₄ solutions are generally used for foliar sprays as they dissolve readily and are absorbed through leaf cuticles in the Mn²⁺ form.

Typical foliar MnSO₄ rates range from 0.1–0.5% w/v solutions applied at key growth stages to correct observed chlorosis.

5. Environmental and Soil Health Impact

5.1 Leaching & Mobility

MnSO₄: Higher solubility increases the risk of Mn leaching in sandy or high rainfall systems.

MnCO₃: Low solubility reduces immediate losses but also limits plant availability unless properly managed.

5.2 Soil pH Interaction

Excessive sulfate from MnSO₄ can promote slight acidification over time — beneficial in alkaline soils but potentially problematic for pH-sensitive systems.

Carbonate from MnCO₃ can raise pH micro-zones, potentially affecting micronutrient balance (e.g., iron, zinc).

6. Economic Considerations

When comparing cost, one must consider:

Price per kg of product

Actual Mn content

Plant-available Mn, not just total Mn

Cost efficiency metric:

Cost per gram of plant-available Mn²⁺

Typically:

MnSO₄ provides quicker Mn²⁺ availability, so its effective cost per unit of plant-available micronutrient may be lower than a higher total Mn content product with low solubility.

7. Which One is “Better”?

There is no one-size-fits-all answer. Selection depends on soil pH, deficiency severity, timing, crop, and method of application.

Use MnSO₄ when:

Rapid correction is needed.

Foliar application is planned.

Soil pH is neutral to acidic.

Use MnCO₃ when:

A slow, sustained supply is desired.

Soil pH is slightly acidic to neutral and buffering is beneficial.

Combined with acids or biological amendments to improve dissolution.

8. Practical Selection Guide

Decision Tree (Simplified)

Do soil tests show Mn deficiency?

Yes → Go to 2

No → Routine Mn program

Is immediate correction required?

Yes → MnSO₄, with possible foliar spray.

No → Consider soil-applied MnCO₃ + MnSO₄ across seasons.

Is soil alkaline (pH ≥ 7.5)?

Yes → Combine MnSO₄ with pH buffering agents; MnCO₃ alone is not sufficient.

No → MnSO₄ alone is typically effective.

9. Summary Table: Pros & Cons

| Criteria | Manganese Sulfate | Manganese Carbonate |

|---|---|---|

| Immediate availability | ???? High | ???? Low |

| Solubility | ???? High (~33 g/100 mL) | ???? Low (<1 g/100 mL) |

| Foliar use | ✔️ Yes | ❌ No |

| Soil buffering | Slight acidify | Moderate buffer |

| Best for acidic soils | ✔️ Yes | ⚠️ Fair |

| Best for alkaline soils | With amendments | Limited solo |

10. Final Recommendation Checklist (For Agronomists & Buyers)

✔️ Perform soil and tissue Mn tests before amendment.

✔️ Adjust for soil pH: acidic soils need less Mn; alkaline soils need combination strategies.

✔️ Choose MnSO₄ for rapid correction and foliar applications.

✔️ Consider MnCO₃ for slow-release programs combined with soil conditioners.

✔️ Always calculate cost per plant-available Mn²⁺, not just total Mn content.

✔️ Monitor crop response and adjust subsequent applications.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.