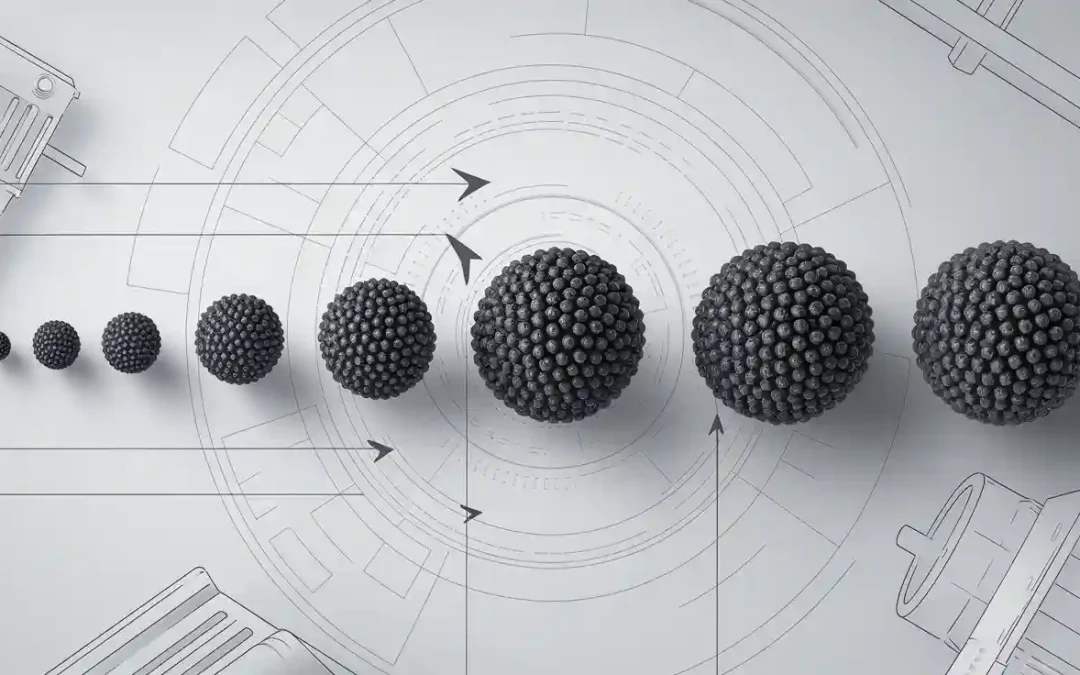

Manganese carbonate particle size is very important for how materials work in many industries. Smaller particles can make things react faster, last longer, and work better.

In pharmaceuticals, small particles help medicine dissolve and work in the body.

In coatings, they help make surfaces smoother.

In environmental uses, smaller size helps things stick and react faster.

How the particles are spread out and made changes these results a lot. Careful planning helps companies get the best results for each use.

Smaller manganese carbonate particles work better. They make reactions faster and more efficient in many uses. – You can control particle size by changing pH or temperature. This helps make special solutions for things like medicine and cleaning the environment. – The best particle size is between 0.074 mm and 0.019 mm. This size helps manganese carbonate soak up more and remove more pollution. – Mixing different particle sizes makes the mixture more stable. It also stops clumping and helps cleaning and factory work. – Using very pure materials and careful methods can save money. It also helps manganese carbonate work better and cost less.

Manganese Carbonate Particle Size and Performance

Main Effects of Particle Size

The size of manganese carbonate particles is very important. It helps decide how well materials work today. Scientists found that many things can change the size of these nanoparticles. These things are how much manganese and carbonate are used, how fast the chemicals are mixed, and the heat level. Each thing can change how the nanoparticles act and how good they are for different jobs.

Manganese amount changes how nanoparticles grow and form.

Carbonate amount controls how fast particles are made.

How fast chemicals are added changes how even the particles are.

Heat changes the size and shape of the particles.

Note: If these things are controlled well, companies can make manganese carbonate nanoparticles with the right size and features.

A study found that smaller particles help manganese ores break down faster. When it is hot, small particles make the process work better. So, using small manganese carbonate nanoparticles helps things happen faster and work better. This is very important in factories and for the environment, where speed and working well are needed.

Mechanisms of Performance Enhancement

Smaller manganese carbonate particles help things work better in many ways. When the particles are tiny, they have more surface area. This means more reactions can happen at once. This is very helpful for cleaning the environment and in chemical reactions.

Heating and changing manganese makes particles smaller and gives more places for reactions.

Turning carbonate into CO2 makes the particles more open and lets things pass through.

Water sticking to the particles helps them break apart when heated.

Gases made when heating help break up the particles and make them smaller.

Manganese spread out in materials helps start more particles, making them more even.

Manganese and other metals give more places for reactions, helping electrons move and making reactions faster.

Mechanism | Effect on Nanoparticles | Impact on Performance |

|---|---|---|

Smaller, more open nanoparticles | Faster reactions | |

Oxidation to CO2 | More open spaces | Better cleaning of pollution |

Water Adsorption | Helps break particles apart | Makes them more stable |

Manganese Distribution | More places for particles to start | Same size particles |

Transition Metal Active Sites | More places for reactions | Better at speeding reactions |

These reasons show why small manganese carbonate nanoparticles work better. Small particles make reactions happen faster and help things work better in many jobs.

Manganese Carbonate Properties

Physical and Chemical Characteristics

Manganese carbonate is used in many science and industry jobs. Its formula is MnCO₃. It looks white or light pink and is a solid. It is pretty heavy, with a density of 3.12 g·cm⁻³. This makes it easy to notice in mixtures. It does not really dissolve in water. But it can dissolve in acids. It will not dissolve in alcohol or ammonia. It starts to break down at about 200 °C. Its crystals have a hexagonal–rhombohedral shape. The heat capacity is 94.8 J·mol⁻¹·K⁻¹.

Property | Value |

|---|---|

Formula | MnCO₃ |

Molar Mass | 114.95 g·mol⁻¹ |

Appearance | White to faint pink solid |

Density | 3.12 g·cm⁻³ |

Solubility | Negligible in water; soluble in acid; insoluble in alcohol, ammonia |

Decomposition Temperature | ~200 °C |

Crystal System | Hexagonal–rhombohedral |

Heat Capacity | 94.8 J·mol⁻¹·K⁻¹ |

To make fine manganese carbonate, people mix manganese(II) nitrate with ammonia and carbon dioxide. Changing the pH and temperature helps control the size of the crystals. Lower pH makes tiny particles. Higher pH makes bigger, grainy solids.

Tip: Changing the pH and temperature lets you pick the crystal size you want. This helps manganese carbonate work better for different uses.

Importance of Particle Size

The size of the particles changes how manganese carbonate works with other things. Small particles mix better and dissolve faster. This helps them react more in chemical jobs. Big particles do not mix as well and react slower. When particles are small, they have more surface area. This makes them work better in chemical reactions.

Small particles react and dissolve faster.

Fine particles are best for chemical jobs.

Big particles slow down mixing and reactions.

Particle Size Effect | Performance Outcome |

|---|---|

Fine particles | Enhanced reactivity, faster dissolution |

Coarse particles | Uneven mixing, slower reactions |

Manganese carbonate with the right particle size mixes well and reacts quickly. This makes it useful for companies that need strong materials.

Recovery Efficiency Optimization

Particle Size Impact on Recovery

How well manganese carbonate works depends on its particle size. Small particles have more surface area than big ones. This means they can grab more unwanted stuff. More surface area helps them clean up better and faster. When companies use fine particles, they see better results. The adsorbent traps more pollution and works quicker.

Scientists see that small particles help with adsorption. Fine particles make the adsorbent work better. Big particles slow down the cleaning process. It also matters if the particles are all the same size. If they are, the adsorbent works even better. How the particles are made changes their size. Good methods make smaller particles and help them clean more.

Note: Companies should use the best ways to make small particles. This helps them get better results and clean the environment faster.

Optimal Size Ranges

Researchers found the best size for manganese carbonate is between 0.074 mm and 0.019 mm. This size range helps the adsorbent work its best. The table below shows the best conditions for top performance:

Optimal Particle Size Range | Additional Conditions |

|---|---|

Pulse Impulse Time: 200 r/min, Magnetic Field Intensity: 1.2 T |

When particles are this size, they remove more pollution. The adsorbent keeps working well and fast. These conditions help companies do a better job. The right size makes adsorption better and boosts removal. This helps companies work faster and clean more. Fine particles with high adsorption are best for the environment.

Catalytic Performance

Manganese carbonate nanoparticles help in many chemical jobs. Their surface area is very important for how well they work. When the surface area gets bigger, there are more active sites. This means more places for reactions to happen. More active sites help with adsorption and cleaning. Scientists see some things when using nanoparticles with high surface area:

More active sites make adsorption better.

Active sites spread out well, so pollutants go away faster.

If the surface area is low, adsorption does not work as well and reactions slow down.

High surface area helps clean the environment by making more reactions happen.

These reasons explain why companies use manganese carbonate nanoparticles for cleaning. The materials work best when they have a large surface area. This makes adsorption and removal easier and faster.

Particle Size and Reaction Rates

The size of manganese carbonate nanoparticles changes how fast reactions go. Smaller particles have more surface area. This gives more spots for adsorption. Scientists found that changing particle size changes the oxidation states of metals inside. This can make the nanoparticles work better and speed up cleaning. The table below shows how particle size affects reaction speed and adsorption:

Particle Size (nm) | Adsorption Efficiency | Reaction Rate | Removal Capability | |

|---|---|---|---|---|

Large | Low | Moderate | Slow | Limited |

Medium | Moderate | Good | Average | Improved |

Small | High | Excellent | Fast | Maximum |

Small manganese carbonate nanoparticles have higher adsorption and faster reactions. These things help companies remove more pollution. The materials are more useful for cleaning and other jobs. By picking the right particle size, companies can make adsorption and reactions work best for what they need.

Material Stability

Mixed Particle Sizes for Stability

Engineers use different manganese carbonate particle sizes to make materials stable. Mixing big and small nanoparticles helps stop them from sticking together. If only small nanoparticles are used, they can clump up. This makes adsorption not work as well. Adding big particles keeps the mix loose and easy to move. The mix also helps with cleaning the environment. Big particles make gaps between the small ones. These gaps let more pollution reach the nanoparticles. The mix works well in filters and reactors. Scientists see that using both sizes keeps adsorption high for a long time.

Tip: Companies should try different mixes of particle sizes to get the best stability for their needs.

The table below shows how mixing particle sizes changes adsorption and stability:

Particle Size Mix | Adsorption Rate | Stability Over Time |

|---|---|---|

Only Small | High | Low |

Only Large | Low | High |

Mixed Small and Large | High | High |

Effects on Storage and Handling

Storing and handling manganese carbonate nanoparticles needs careful steps. Small nanoparticles can turn into dust. This dust can lower how well they adsorb things. Workers need to use closed containers to keep adsorption strong. Mixing particle sizes makes less dust and is safer to handle. Companies use special bags and bins to store these materials. They check the bins often to keep adsorption high. In environmental work, safe storage keeps nanoparticles ready to use. Good handling keeps workers safe and adsorption steady.

Store in closed containers.

Mix particle sizes to cut down dust.

Check bins for changes in adsorption.

Teach workers how to handle materials safely.

Note: Storing and handling the right way helps companies keep adsorption high and protect the environment.

Synthesis and Particle Size Control

Thermal Exfoliation and Metal Salts

Making manganese carbonate is important for changing particle size. Scientists use different ways to make it, like hydrothermal, solvothermal, sol–gel, and carbonate co-precipitation. These ways help change how big or small the nanoparticles are. Micro-emulsions let scientists control the size and spread of the particles very well. This makes it easier to get even nanoparticles. Direct precipitation also makes small particles with a lot of surface area.

Tip: Changing how much manganese and carbonate you use, how fast you add chemicals, and the temperature can change the final particle size.

Parameter | Influence on Particle Size |

|---|---|

Big effect on particle size | |

Carbonate Concentration | Big effect on particle size |

Flow Rate of Reagent Addition | Big effect on particle size |

Temperature | Big effect on particle size |

Thermal exfoliation and using metal salts help make smaller and more active manganese carbonate nanoparticles. These ways also let scientists change the crystal shape and make more surface area. This helps the materials work better in many jobs.

Nucleation and Particle Formation

How fast nucleation happens changes how fine the particles are. If there is a lot of manganese compared to silicon, the process makes tiny nanoparticles. These are only a few nanometers wide. If the ratio is lower, very thin nanowires can form, sometimes less than 10 nm wide. This means controlling nucleation is important for getting the right size and shape.

Scientists have some problems when they try to control particle size. The structure can change, and there are different oxidation states. The crystal shape can also change if the Co/Mn ratio is different. The Jahn–Teller effect from Mn3+ can twist the crystal, making it harder to form particles.

Sol–gel method

Carbonate co-precipitation

These ways help change the crystal shape and make small particles. They also make manganese carbonate nanoparticles with lots of surface area.

Advantage | Explanation |

|---|---|

Smaller particles have more surface area, so they react better in chemical jobs. | |

Versatile Applications | Microparticles can be used in many things, like farming and factories. |

Nutritional Enhancement | They give plants and animals more manganese for their diet. |

If scientists control how they make the nanoparticles, they get better quality. This makes the materials work better and lets them be used in more ways.

Optimization Strategies

Selecting Particle Size for Applications

Picking the right manganese carbonate particle size is very important. Engineers and scientists check what each job needs before they choose a size. They think about how adsorption, reaction speed, and removal will change with different sizes. Small nanoparticles have more surface area. This helps them adsorb more and react faster. It also helps remove pollution in the environment.

A battery company needs the same particle size every time. When nanoparticles are all the same, batteries work better and last longer. In 2002, battery makers used over 230,000 tons of manganese dioxide. This shows why having the right size is important for good results. When the particle size fits the job, companies get better adsorption and removal.

Changing how you make the particles helps control their size. Adjusting heat, how fast chemicals are added, and how much you use can change the size. This helps make nanoparticles that adsorb and react better. It makes them work well in factories and for cleaning up.

Tip: Engineers should pick the particle size for each job. Small nanoparticles are best for fast adsorption and removal. Bigger ones are better when you need more stability.

Application Area | Preferred Particle Size | Reason for Selection |

|---|---|---|

Battery Manufacturing | Fine nanoparticles | High adsorption, fast reaction |

Water Treatment | Fine nanoparticles | Maximum removal of pollutants |

Ceramic Glazes | Mixed particles | Smooth finish, reduced defects |

Catalysis | Fine nanoparticles | Enhanced reaction rates |

Balancing Performance and Cost

Companies want good performance but also need to save money. The size of manganese carbonate particles changes both how well they work and how much they cost. Small nanoparticles work better but cost more to make.

Using pure manganese carbonate helps companies waste less and adsorb more. One electronics company lowered waste by 15% by using pure manganese carbonate. This made their products better and saved money.

Pure materials help waste less and adsorb more.

Same-size nanoparticles lower waste and remove more.

Good ways to make particles save money and work better.

Keeping the size the same helps reactions and saves energy.

Think of MnCO₃ as a ‘thermal lubricant’ for glazes. It helps melting and makes fewer problems. This can save energy and make better products.

Engineers use different ways to balance cost and performance. They pick ways to make nanoparticles that do not waste materials. By controlling size and spread, companies get strong adsorption and reaction without spending too much.

Strategy | Impact on Performance | Impact on Cost |

|---|---|---|

Use of high-purity materials | Higher adsorption | Lower reject rates |

Controlled synthesis parameters | Better reaction | Efficient resource use |

Mixed particle sizes | Stable removal | Reduced handling costs |

Changing how you make the particles helps companies get the best mix of cost and performance. Picking the right size helps with adsorption, reaction, and removal. This makes manganese carbonate better for cleaning and factory jobs.

Manganese carbonate particle size is very important for how things work. Research shows that small particles help remove more pollution. Careful mixing and making of particles can help recovery reach 87.14%. Companies need to pick the best way to make manganese carbonate. They should also control the size of the particles. This helps remove more pollution and keeps performance steady. The table below shows the main results:

Parameter | Value |

|---|---|

Optimum particle radius | 0.074-0.019 mm |

Recovery rate | 76.85% |

Fine particle distribution | High removal |

To get the best results, engineers should pay attention to how they make the particles. They should also look at particle size and how well things are removed when making new materials.

FAQ

What is the best particle size for manganese carbonate in industrial applications?

Scientists say the best size is between 0.074 mm and 0.019 mm. This size helps companies get fast reactions and high recovery. Engineers pick the size that fits what each job needs.

How does particle size affect the stability of manganese carbonate?

Using both big and small particles makes manganese carbonate more stable. Big particles stop clumps from forming. Small particles help the material react better. Companies mix sizes to keep the material easy to use and working well.

Can particle size influence the cost of production?

Making smaller particles costs more money. It needs special ways to make and control them. Companies try to save money and still get good results by picking the right size for each job.

Why do companies focus on particle size when designing new materials?

Particle size changes how well manganese carbonate works in reactions. Engineers pick the best size to help with adsorption, reaction speed, and removal. The right size lets companies make strong materials for many uses.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.