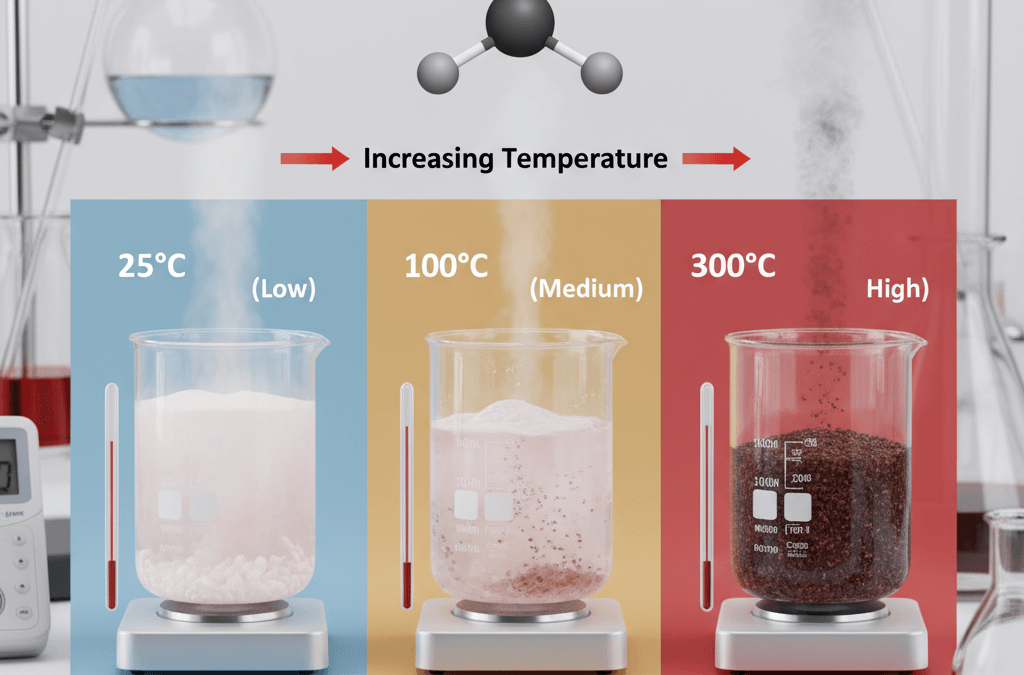

Manganese carbonate (MnCO₃) starts to decompose when heated, forming manganese oxide (MnO) and releasing carbon dioxide. The key decomposition temperature is typically around 300–400°C, depending on purity and processing conditions. Understanding this temperature range is crucial for safe production, efficient calcination, and consistent product quality in industries such as batteries, ceramics, and catalysts.

The Chemical Nature of Manganese Carbonate

Manganese carbonate (MnCO₃) is an inorganic salt, sometimes found as the mineral rhodochrosite, with a relatively simple formula yet complex behaviour under thermal and chemical stress. According to its Wikipedia entry, manganese(II) carbonate “decomposes with release of carbon dioxide, i.e. calcining, at ~200 °C to give MnO₁.₈” under certain conditions.

Structural and stability factors

Several factors affect the stability of MnCO₃:

Crystal structure: The rhombohedral/mineral form and the purity of the material affect how easily decomposition or phase transformation occurs.

Purity / impurities: The presence of other ions or moisture can lower or raise the decomposition temperature by altering mass transport or gas evolution.

Atmosphere and heating rate: Whether the environment is inert, air, CO₂-rich or vacuum influences thermal behaviour. For example, a higher heating rate tends to increase the terminative temperature of decomposition.

Particle size and sample mass: Smaller particles or less mass lead to faster heat and mass transfer, altering the apparent decomposition onset. The kinetics of carbonates in general depend on these parameters.

Because of these factors, a “one‐size” decomposition temperature for MnCO₃ does not always apply universally; rather, the actual behaviour depends on manufacturing, handling, and testing conditions.

Thermal Stability and Decomposition Mechanism

In this section we discuss how temperature affects MnCO₃ stability, what reactions occur at various temperatures, and the implications of those reactions for material performance.

Onset of decomposition

Several sources indicate the start of MnCO₃ decomposition at surprisingly low temperatures under certain conditions. One reference states that MnCO₃ decomposes to MnO at ~200 °C with release of CO₂.

Another thermodynamic/experimental study indicates that calcination of MnCO₃ must be higher than ~345.5 °C to begin decomposition in their setup.

Thus, realistic onset depends on atmosphere, heating rate, sample size etc.

Reaction pathways and products

A principal decomposition reaction of MnCO₃ can be written:

In more complex conditions, e.g., slower removal of CO or exposure to oxygen, higher manganese oxides such as Mn₃O₄ or manganese dioxide (MnO₂) may form. For example, a study found that under inert flow, the weight loss corresponded to formation of MnO and/or Mn₃O₄ depending on gas removal rate.

Another study cites that temperatures above ~300 °C lead to conversion of MnCO₃ into MnO in nanoparticle synthesis.

Temperature‐dependent behaviour and kinetics

Temperature not only influences whether decomposition occurs, but also how fast and what product phases result. Some key data:

According to the thermogravimetric study “Thermal Decomposition of MnCO₃ (In Air)”, the apparent activation energy for MnCO₃ decomposition in air was found to be Eₐ ≈ 102 kJ/mol.

The study “Thermal Decomposition Kinetics of Carbonaceous and Ferruginous Manganese Ores” indicates carbonate minerals in manganese ores decomposed at temperatures above ~900 °C in atmospheric conditions.

These illustrate that conditions like mineral form, impurity, and atmosphere make a large difference.

Summary table: Temperature ranges and typical behaviour

Below is a table summarising typical temperature ranges and associated behaviour for MnCO₃ (and similar manganese carbonates) under various conditions:

| Temperature (°C) | Observed behaviour | Notes / Source |

|---|---|---|

| < 200 °C | Some decomposition onset under loose conditions (e.g., 200 °C) | Digitalfire summary |

| ~200-350 °C | Clear decomposition to MnO + CO₂ in many low‐mass/heating‐rate experiments | Nanoparticle synthesis study: MnCO₃ ≥300 °C → MnO |

| ~345 °C | Minimum calcination temperature indicated in one study for beginning decomposition of MnCO₃ | SCIRP study |

| >300-600 °C | More complete decomposition; formation of higher oxides possible depending on atmosphere | Westerdahl & Leader (1969) |

| >900 °C | In ore/mineral context (with carbonate gangue), decomposition of manganese‐carbonate minerals may require this high temperature | SAIMM article |

Practical implication of kinetics and temperature control

Heating rate matters: A faster heating rate tends to shift decomposition to higher apparent temperatures because of lag in heat/mass transfer. [“Thermal Decomposition Kinetics…”]

Atmosphere matters: In an inert atmosphere or with restricted gas removal, secondary oxidation reactions or incomplete decomposition may yield higher oxides instead of simple MnO. The presence of residual CO/CO₂ influences final phases.

Sample mass/geometry matters: Larger sample mass or thicker particle size delays heat transfer, so onset may be higher and less sharp.

Resulting product phases matter: For manufacturers using MnCO₃ as a precursor (for e.g., MnO₂, battery materials), controlling temperature and atmosphere precisely ensures the desired oxide phase and avoids unwanted phases which may degrade performance or increase cost.

Industrial Implications of Temperature Control

Now we move from laboratory behaviour to the industrial implications of temperature (and stability) for manufacturers and users of manganese carbonate.

Applications and temperature relevance

Ceramics and glazes

MnCO₃ is often used as a colorant or flux in ceramic glazes. During the kiln firing process, temperature control is vital: if decomposition happens too early, the oxide formed may not evenly be incorporated; if it happens too late, CO₂ release may cause bubbling or defects. The onset of decomposition (~200-350 °C upwards) informs how the glaze schedule should be tuned.

Battery and catalyst precursor

MnCO₃ is used as a precursor for manganese oxides (MnO₂, Mn₃O₄, etc) which serve as electrode/catalyst materials. In this field, achieving a specific oxide phase (and particle morphology) is critical. Precise temperature control (and atmosphere) allows conversion of MnCO₃ into the right oxide while preserving desired microstructure. For example, a team preparing Gd-doped MnCO₃ noted that above ~300 °C it tends to transform into MnO, so they optimised synthesis at 280-300 °C for the desired product.

Manganese dioxide production

In a study focused on producing MnO₂ from MnCO₃ via calcination, the authors stated that the calcination temperature must be higher than ~345.5 °C to initiate decomposition of MnCO₃, but also must be lower than ~975 °C to avoid full decomposition of MnO₂, and lower than ~557.98 °C in some oxidation steps. This highlights that for industrial manufacture of MnO₂ from MnCO₃, there is a window of optimal temperature — too low and MnCO₃ remains unreacted; too high and the desired oxide is over‐decomposed or altered.

Quality control and production stability

From a factory perspective (as in your case, manufacturing MnCO₃), controlling temperature during production, post-treatment, storage, and shipping is important for ensuring product stability and consistency.

Producing MnCO₃: If the produced MnCO₃ is inadvertently exposed to elevated temperatures (e.g., above ~300 °C) during drying or processing, partial decomposition may occur, altering composition, release of CO₂, and reducing purity or altering physical properties.

Storage & transport: Although typical ambient temperatures are far below decomposition onset, if storage conditions involve elevated heat (e.g., hot warehouse or near kiln) or if moisture/humidity contributes to later heat uptake, stability may be compromised.

Downstream performance: If MnCO₃ is intended to be used as a precursor, the downstream user relies on predictable conversion behaviour. If your product has partially decomposed or has variable morphology due to heat, performance may degrade—leading to complaints or lost business.

Thus, for your factory it is critical to:Document and control the drying/processing temperatures so they stay well below the threshold where decomposition begins (e.g., <200 °C if possible for drying).

Monitor shipping/warehouse temperatures/humidity to avoid inadvertent thermal stress.

Provide your customers with specification data such as “decomposition onset temperature (TG) > X °C” so they can trust the stability of your grade.

Practical Tips for Storage and Handling

Storage conditions

Store in a cool, dry environment, ideally at ambient temperatures well under ~100 °C and away from direct heat sources.

Avoid exposure to high humidity or steam which may accelerate chemistry or clumping (even though humidity doesn’t directly cause decomposition, it may affect particle integrity).

Use sealed containers or bags to limit ingress of atmospheric CO₂, moisture, which could influence microstructure over time.

Label clearly with “storage temperature: ≤ X °C” if your product has been tested to a specific stability threshold.

Handling before processing

In production, ensure that drying or pre-processing temperatures remain safely below decomposition thresholds. For example, if you choose to keep drying below 120-150 °C, you are well clear of early decomposition regions (~200°-300 °C).

If customers intend to use high-temperature calcination (for conversion to oxides), provide them with technical guidance: “MnCO₃ remains stable until about 300 °C (under controlled conditions) – beyond that decomposition begins; please plan your calcination schedule accordingly.”

Provide thermal analysis data (TGA/DTG) or specification sheets that show weight loss vs temperature, phase change onset, etc. This adds value and reassures customers.

Quality assurance

Consider implementing a TG-DTA (thermogravimetric + differential thermal analysis) test on your MnCO₃ batches to measure weight loss onset vs temperature and document the data for each batch.

In your product specification sheet, you might include:

Decomposition onset temperature (°C) at a standard heating rate (e.g., 10 °C/min in air)

Activation energy for decomposition (if you measure)

Phase purity and residual oxide content (if any)

Conclusion

In summary:

The stability of manganese carbonate (MnCO₃) against temperature is a significant parameter for both upstream production and downstream usage.

While onset of decomposition can begin at ~200 °C under certain conditions, many industrially relevant thresholds are ~300-350 °C and above, depending on heating rate, atmosphere, sample geometry, and purity.

As temperature increases, MnCO₃ transforms into MnO and other manganese oxides (Mn₃O₄, Mn₂O₃, MnO₂) depending on conditions.

For your factory producing MnCO₃, controlling processing temperature, storage, and providing documented thermal stability creates differentiation and builds trust with customers in ceramics, battery, and catalyst sectors.

By providing clear product specification, technical data (e.g., TG/DTG curves), and handling guidelines, you can position your MnCO₃ as a high-quality, stable material—commanding premium pricing and attracting customers who require reliability.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.