Battery materials are very sensitive to how they are made. One often-overlooked but important factor is particle size — especially when working with precursor powders like manganese carbonate (MnCO₃). Although many buyers focus on purity or chemical composition, the particle size and size distribution (PSD) of MnCO₃ can have a big effect on battery performance, production consistency, and final material behavior.

In this article, we explain why particle size matters, provide real data and cases showing its effect, list common industry standards, and give practical guidance for manufacturers or buyers. If you are sourcing or producing MnCO₃ for Li‑ion battery cathodes/anodes (or for further conversion to Mn oxides), this information is highly relevant.

What is Manganese Carbonate (MnCO₃) and its Role in Batteries

MnCO₃ is a stable manganese salt (chemical formula MnCO₃, molar mass ~114.95 g/mol) commonly used as a precursor for manganese oxides.

In battery manufacturing, MnCO₃ may be used directly (in some anode applications) or more often converted — via calcination — into manganese oxide (e.g. MnO, Mn₂O₃, Mn₃O₄, MnO₂) or incorporated into mixed-metal cathode materials (e.g. Li-Mn-Ni-Co oxides).

The quality of the precursor (MnCO₃) thus strongly influences the morphology, structure, tap density, and electrochemical behavior of the final battery materials.

Because of this key role, particle size and size distribution of MnCO₃ are not just “nice-to-have” — they are often critical parameters.

Why Particle Size & Distribution Matter: Key Mechanisms

Surface Area & Reaction / Conversion Efficiency

Smaller particles (or controlled fine particles) provide higher surface area per unit mass → more sites for reaction, better contact with lithium/electrolyte during conversion.

During calcination (MnCO₃ → Mn oxide) or solid‑state synthesis, fine, uniform precursors tend to convert more completely and with fewer unreacted cores.

Morphology and Uniformity of Final Materials

Uniform particle size and shape help produce consistent morphology in the final oxide or cathode materials. In contrast, broad PSD or irregular shapes can cause non-uniform grain growth, leading to performance inconsistency.

Controlled size helps optimize tap density (important for volumetric energy density) and packing behavior — key for electrodes.

Electrochemical Performance (Capacity, Rate Capability, Cycling Stability)

Fine or appropriately sized particles enhance ion diffusion rates and reaction kinetics → better rate performance (fast charge/discharge).

Uniform PSD reduces mechanical stress, cracking, uneven volume change during cycling, which helps longevity.

Good tap density + uniform packing helps achieve high volumetric energy density.

Manufacturing Consistency, Safety, and Yield

Consistent PSD batch-to-batch → predictable processing (slurry making, calendering, mixing).

Overly large particles (or wide PSD) may lead to poor mixing, segregation, or even safety issues (e.g. uneven heat distribution during calcination).

From a supplier perspective, control over PSD and shape helps ensure stable supply quality — a major differentiator in B2B contexts.

Real Data & Case Studies

Here are some concrete studies and data showing the impact of MnCO₃ particle size (or closely related Mn-based precursor size) on battery performance.

Case Study: MnCO₃ Microspheres for Li-Ion Battery Anodes

A widely cited study tested spherical MnCO₃ powders with different mean diameters — 6.9 μm (MnCO₃-B), 4.0 μm (MnCO₃-M), and 2.6 μm (MnCO₃-S) — as anode materials for lithium-ion batteries.

| Sample ID | Mean Diameter (μm) | Reversible Specific Capacity after 100 Cycles (mAh/g) | Capacity Retention (%) |

|---|---|---|---|

| MnCO₃-B | 6.9 | 487.3 | > 90% |

| MnCO₃‑M | 4.0 | 573.9 | > 90% |

| MnCO₃‑S | 2.6 | 656.8 | > 90% |

Key insight: As the particle size decreased, the specific capacity increased significantly (from ~487 to ~657 mAh/g). The smallest particle size (2.6 μm) yielded the highest capacity. The authors attribute this to conversion of MnCO₃ microspheres into a self‑stabilized porous nanostructured matrix during the first cycles, which preserves electrode integrity and allows for high reversible capacity.

This example clearly shows that even at micrometer scale, reducing particle size — while retaining uniform spherical morphology — can dramatically improve electrochemical performance in Li-ion battery anodes.

Industry / Patent Standards for Cathode Precursor Powders

When MnCO₃ (or mixed-metal carbonates) is used as a cathode precursor (e.g. for Li-rich Mn-based oxides), industry practices or patent documents often specify target PSD and tap density to ensure good battery behavior:

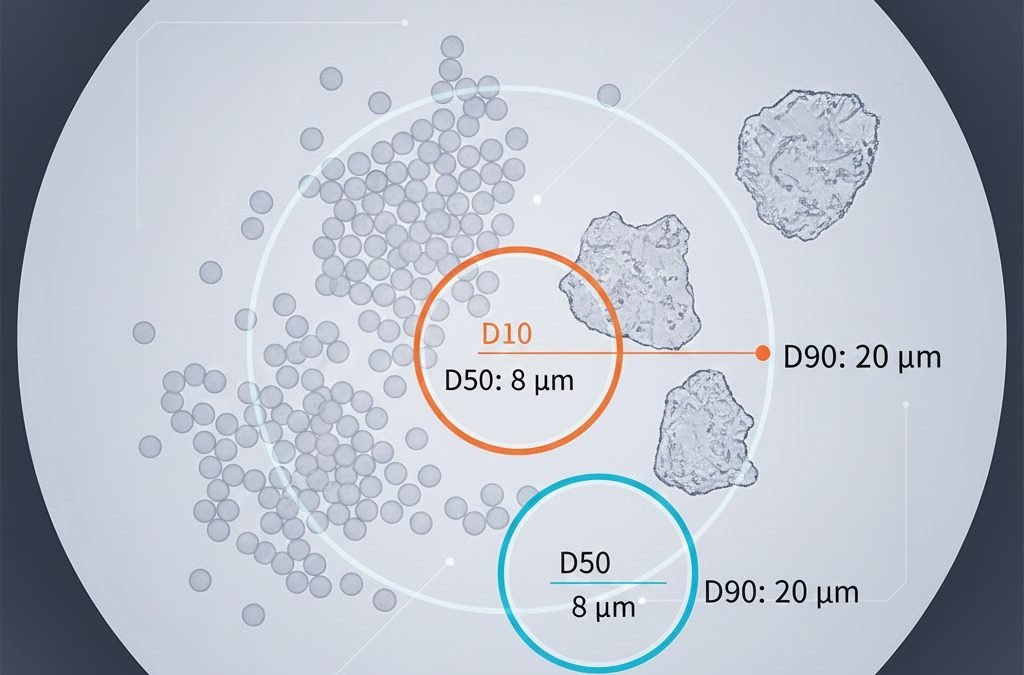

One patent describes a carbonate precursor with secondary particle size D50 in μm, and a particle size span S = (D90 − D10) / D50 ≤ 1.8 for good uniformity.

Another preference is a D50 of 6.0–14.0 μm, more preferably 9.0–12.0 μm.

For tap density, the same patent suggests TD between 1.8 and 2.6 g/cm³, or more preferably 2.0–2.4 g/cm³.

These ranges indicate what many battery manufacturers consider acceptable or optimal for Mn-based cathode precursors: not ultra-fine nanoscale powders, but controlled, uniform micropowders with narrow PSD and reasonable tap density for good packing and performance.

Manufacturing Process & Effects on Particle Size

How particle size is controlled in production matters. Several studies (and industrial reports) show how precipitation parameters affect MnCO₃ size and distribution:

In one report on battery-grade spherical MnCO₃, by controlling flow rate of manganese sulfate solution, stirring speed, pH, temperature, they achieved near-spherical particles with uniform size. Under optimized conditions (pH 7.5, 60 °C, flow rate 30 mL/min, stirring 600 rpm), they achieved average particle size around 11.13 μm, high Mn content (~46.22%), low impurities, and narrow distribution.

In a synthesis of a mixed-metal carbonate (Fe₀.₅Mn₀.₅CO₃), the authors showed that temperature, pH, and stirring rate influence D50. For example, they obtained particles of ~10 μm D50 at 50 °C and pH 8 using a 6‑h batch coprecipitation. Lower temperature or different pH yielded smaller or larger particles.

Another academic study using MnCO₃ precipitation demonstrated that metal concentration (supersaturation level) affects crystal shape and size: as concentration increases, particles shift from rhombohedral to cubic to spherical shapes, and size decreases under fast growth kinetics.

These studies show that manufacturing control — not just raw chemistry — directly determines particle size, shape, and uniformity, which will ultimately influence battery-grade powder quality.

How Particle Size Impacts Final Oxide & Electrode Performance

It’s not only the precursor stage that matters. The size and morphology of MnCO₃ affect how it converts during calcination and how the final manganese oxide behaves:

A recent study on manganese oxides shows that crystallite size, morphology, specific surface area, compaction density, and electrochemical behavior change significantly depending on the precursor morphology and calcination process.

For example, the study produced different crystalline forms of Mn₃O₄ (rod-type, etc.) via a liquid-phase method and then calcined them. The “rod-type” Mn₃O₄ showed a high specific surface area of ~63.9 m²/g, low compaction density, and — when used as an LIB anode — delivered specific capacity of ~666.5 mAh/g at 1C, and retained ~382.2 mAh/g after 200 cycles.

These results demonstrate that starting from a well-controlled carbonate precursor → proper calcination → controlled morphology directly leads to oxide materials with excellent electrochemical properties.

Thus, poor control at the carbonate stage (e.g. broad PSD, irregular shape) can lead to inconsistent oxides with sub-optimal surface area, density, and ultimately lower capacity or poor cycling stability.

Recommended Particle Size / Distribution Standards for Battery-Grade MnCO₃

Based on industry practices, patent specifications, and academic cases, the following table summarizes typical target particle size and distribution parameters for battery-grade MnCO₃ (or mixed carbonate) powders.

| Application / Use | Typical / Preferred D50 (μm) | Preferred PSD Span / D90‑D10 / D50 | Tap Density (g/cm³) |

|---|---|---|---|

| Li‑rich manganese-based cathode precursor | 6.0 – 14.0 (preferably 9.0 – 12.0) | Span ≤ 1.8 | 1.8 – 2.6 (preferably 2.0 – 2.4) |

| Battery‑grade generalized MnCO₃ powder | ≤ ~15 µm, ideally ~5–12 µm (depending on final oxide) | Narrow distribution, uniform spherical shape (for consistent calcination) | High tap density is desirable for volumetric energy density |

| Special high‑performance anode use (microspheres) | 2–7 µm (as demonstrated in literature) | Uniform microspheres preferred | — |

From the above, we can see that “fine but not ultra‑fine” micropowders (single-digit to low‑two-digit µm) with narrow PSD and good tap density/packing are the mainstream for battery-grade MnCO₃. For special use‑cases (like microsphere anodes), even smaller sizes (2–5 µm) may bring benefit.

Practical Recommendations for MnCO₃ Suppliers & Buyers

If you are producing or sourcing MnCO₃ for battery use, here are some practical takeaways:

Control precipitation parameters carefully

Adjust pH, temperature, metal-ion concentration, flow rate (if in continuous precipitation), stirring speed — these all strongly influence final particle size and morphology. As shown in studies, optimized parameters can yield ~11 μm spherical particles with narrow distribution and high tap density.

A span S = (D90 − D10) / D50 ≤ 1.8 is often used in patents for cathode precursors.

Uniform particles help ensure consistent calcination, uniform oxide formation, stable packing density, and reproducible electrochemical behavior.

Provide both PSD data and tap density when offering product to battery manufacturers

Tapping density often matters for volumetric energy density. For cathode precursors, 1.8–2.6 g/cm³ (ideal ~2.0–2.4 g/cm³) is often cited.

Suppliers should offer PSD reports (D10, D50, D90) plus morphology images (e.g. SEM) and tap density — this improves buyer confidence.

Match particle size to application

For cathode precursors used in Li‑Mn cathodes or mixed Li–Mn–Ni–Co oxides, moderate micropowders (6–14 µm) are fine.

For direct use as anode materials (or certain oxide materials where high surface area matters), smaller and uniform particles (2–5 µm) may give performance advantages — as shown in literature.

Avoid uncontrolled production (e.g. continuous precipitation without control), which may lead to very large particles (>30 µm)

According to industry literature, continuous stirred-tank reactor (CSTR) processes often produce large, poorly controlled particles over 30 µm, which are detrimental to battery safety and performance.

If using continuous processes, you need robust process control (flow, mixing, supersaturation, residence time, seeding, etc.) to maintain target PSD.

Document and share batch-to-batch consistency

For B2B buyers (battery manufacturers), stable and consistent powders are critical. Suppliers who can show consistent PSD, morphology, tap density, impurity levels, moisture, etc., will have a competitive advantage.

Limitations and Trade‑Offs

While smaller and more uniform particles often give better performance, there are trade‑offs and risks:

Higher specific surface area → possible side reactions / stability issues

Very fine or high-surface-area powders may more easily react with moisture or CO₂ in air, or cause unwanted side reactions during calcination or battery operation.

For example, in oxide materials, porous or high-surface powders may have lower compaction density, which may reduce volumetric energy density.

Cost and complexity for production

Producing uniform fine powders with narrow PSD often requires more precise control over precipitation, possibly additional milling, classification, and quality control — which increases cost.

For large-scale supply, maintaining consistency batch after batch is not trivial.

Not all applications need ultra-fine powders

For many cathode applications, moderately sized micropowders (6–14 µm) are acceptable or even preferred (for tap density and easier handling). Over-emphasis on “the smaller the better” may be unnecessary or even counterproductive.

Thus, the “best” particle size depends on the target application, battery chemistry, and production capabilities.

Why This Topic Matters for Battery Industry Buyers & Suppliers

As battery demand grows, manufacturers demand consistent, high-quality precursors. A supplier who can deliver MnCO₃ with controlled particle size + narrow distribution + good tap density will be more competitive.

For companies seeking to optimize battery capacity, rate performance, or cycle life, paying attention to precursor PSD may yield substantial gains — sometimes without changing chemistry, just by better physical powder properties.

With increasing interest in high‑manganese cathodes for cost reduction, safety, or supply-chain resilience, having a reliable MnCO₃ supply with tight specs becomes more strategic.

From an OEM or battery maker perspective, specifying and auditing PSD and tap density of incoming powders should become part of quality control, not optional extras.

Conclusion

Particle size and size distribution of MnCO₃ are far from trivial details — they play a key role in determining how well a battery performs. As shown:

Smaller, uniform MnCO₃ particles (e.g. 2–5 µm microspheres) can dramatically improve anode capacity and cycling performance.

For cathode precursors, industry and patents typically aim for D50 in the range of 6–14 µm (preferably 9–12 µm), narrow PSD, and reasonable tap density — to ensure good packing, consistent structure, and reliable electrochemical behavior. Manufacturing process parameters — pH, concentration, flow rate, stirring, temperature — directly affect the final particle size and morphology.

Poor control (e.g. leading to very large or widely distributed particles) can compromise battery performance, consistency, and safety.

For MnCO₃ suppliers, producing powders with tightly controlled PSD + uniform morphology + consistent batch quality is an important differentiator and a foundation for high-quality battery materials.

If you are a buyer (battery manufacturer), it is wise to specify PSD (D10, D50, D90), tap density, morphology (e.g. SEM), and batch consistency when sourcing MnCO₃ — not just chemical purity.

In short: particle size is not a minor variable — it’s a critical lever for battery performance, manufacturing consistency, and overall material quality.

FAQ

Q1: Why is manganese carbonate particle size important for batteries?

A: Particle size affects reaction efficiency, morphology, and uniformity of the final manganese oxide or cathode material. Smaller, uniform particles improve lithium-ion diffusion, enhance specific capacity, and support better cycle life.

Q2: What is the ideal particle size range for battery-grade MnCO₃?

A: For cathode precursors, D50 is usually 6–14 µm (preferably 9–12 µm) with a narrow PSD (span ≤ 1.8). For special anode applications or microspheres, D50 may be 2–5 µm. Tap density should typically be 1.8–2.6 g/cm³.

Q3: How does particle size affect calcination and final MnO₂ structure?

A: Smaller and uniform MnCO₃ particles convert more completely and evenly during calcination, producing oxides with consistent morphology, surface area, and density. Large or irregular particles can lead to unreacted cores, non-uniform grain growth, and inconsistent electrochemical performance.

Q4: Can I improve battery performance by simply using smaller particles?

A: Not always. Extremely fine powders can increase surface area too much, causing side reactions, moisture sensitivity, or lower tap density. The key is controlled particle size with uniform morphology, tailored to the specific battery application.

Q5: How do manufacturers control MnCO₃ particle size?

A: Common methods include controlling pH, temperature, metal ion concentration, flow rate, stirring speed, and adding seed crystals during precipitation. Post-processing like milling and classification may also be used to achieve the desired PSD and morphology.

Q6: Why should buyers request PSD and tap density data?

A: Providing D10, D50, D90, tap density, and morphology images ensures batch-to-batch consistency. These data help predict electrode packing density, electrochemical behavior, and overall battery performance, reducing production risk.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.