Selecting between manganese steel vs carbon steel in 2025 requires a clear understanding of each material’s unique properties and best-fit applications. Carbon steel dominates general construction due to its balance of strength, ductility, and cost-effectiveness, while manganese steel excels in high-impact environments where superior toughness and wear resistance are critical. Engineers consider factors such as load-bearing demands, environmental conditions, and expected performance. The table below highlights the latest global usage trends:

Aspect | Carbon Steel (2025) | Manganese (2025) |

|---|---|---|

Estimated Production Volume | ||

Market Size | ~$50 billion USD | Rapid growth in batteries, steel alloys |

Key Sectors | Construction, automotive, machinery | Steelmaking, energy storage, EV batteries |

Manganese carbonate remains essential in alloy production, supporting evolving industry needs.

- Manganese steel offers superior toughness and wear resistance due to its high manganese content and unique work-hardening ability, making it ideal for high-impact and abrasive environments.

- Carbon steel provides higher initial hardness, better machinability, and lower cost, making it suitable for general construction, automotive, and precision tool applications.

- Choosing the right steel depends on the application’s demands: use manganese steel for heavy-duty, impact-prone uses and carbon steel for cost-effective, easy-to-fabricate projects.

- Manganese steel requires special heat treatment and careful welding to maintain its properties, while carbon steel is easier to produce, weld, and machine.

- Supply chain factors and cost differences in 2025 affect availability; manganese steel may face price volatility, while carbon steel remains widely available and affordable.

Key Differences

A comparative analysis of manganese steel vs carbon steel reveals significant distinctions in both chemical composition and mechanical behavior. Manganese steel, often called Hadfield steel, contains approximately 12-14% manganese and about 1.2% carbon. This high manganese content stabilizes the austenitic microstructure, enabling unique deformation mechanisms such as twinning-induced plasticity (TWIP) and transformation-induced plasticity (TRIP). These mechanisms enhance strain hardening and toughness, making manganese steel highly resistant to wear and impact.

Carbon steel, by contrast, features a carbon content ranging from 0.6% to 1.4% and much lower manganese levels. Its microstructure typically includes martensite, ferrite, or bainite phases, which provide higher initial hardness and tensile strength. However, carbon steel lacks the dynamic strain hardening found in manganese steel, resulting in lower toughness and wear resistance.

Note: The following table summarizes the key differences between manganese steel and carbon steel, focusing on their physical and chemical properties.

Property/Aspect | Manganese Steel (Hadfield Steel) | High Carbon Steel |

|---|---|---|

Chemical Composition | ~12-14% Mn, ~1.2% C (Hadfield’s 10:1 Mn/C ratio) | 0.6% to 1.4% C, low Mn content |

Microstructure | Austenitic, TWIP/TRIP mechanisms | Martensite, ferrite, bainite phases |

Physical Properties | Exceptional toughness, work hardening, high wear resistance | Higher initial hardness, easier machinability, lower toughness |

Deformation Mechanisms | TWIP, TRIP, dynamic strain hardening | Hardness from carbon, lacks work hardening |

Alloying Effects | Al, Cr, Mo, Si, N, V improve resistance | Fewer alloying elements, mainly carbon |

Mechanical Behavior (Strain) | Dynamic strain aging, delayed fracture possible | Stable under strain |

This comparative analysis demonstrates that manganese steel excels in environments where impact and abrasion dominate, while carbon steel performs best in applications demanding high initial hardness and tensile strength.

Mechanical performance metrics further highlight the key differences. Manganese steel starts with a Brinell hardness of about 220 BHN but can work-harden up to 550 BHN under repeated impact. Its toughness remains excellent, and it offers very high wear resistance. Carbon steel, on the other hand, provides higher initial hardness and tensile strength but does not work-harden and has lower toughness.

Property | High Manganese Steel (Hadfield Steel) | High Carbon Steel |

|---|---|---|

Composition | 12-14% manganese | 0.60% – 1.4% carbon |

Hardness | Higher initial hardness | |

Toughness | Excellent toughness | Lower toughness |

Wear Resistance | Very high | Lower |

Tensile Strength | Good, lower than high carbon steel | Higher tensile strength |

Work Hardening | Significant under impact/wear | Does not work-harden |

Machinability | Poor | Easier to machine |

Manganese steel’s ability to work-harden under stress makes it ideal for heavy-duty industrial use. Carbon steel’s higher machinability and tensile strength suit it for precision tools and structural components.

Applications

The application areas for manganese steel vs carbon steel reflect their distinct mechanical properties. Manganese steel finds use in industries where components face extreme wear and impact. Mining operations rely on manganese steel for crusher liners, which must withstand abrasive materials. Railways use it for tracks, benefiting from its toughness and ability to absorb impact forces. Construction sectors employ manganese steel in heavy machinery components, where work hardening and durability are essential.

Industry/Sector | Common Applications | Key Performance Characteristics | Influence on Use |

|---|---|---|---|

Mining | Crusher liners | High hardness, wear resistance | Resists abrasive materials in mining |

Railways | Railway tracks | Toughness, impact strength | Supports heavy loads, absorbs train impact |

Construction | Heavy machinery components | Work hardening, toughness | Provides durability in harsh, high-impact environments |

Additional application areas include armor plating for military vehicles and impact-resistant surfaces. These uses leverage manganese steel’s exceptional wear resistance and toughness.

Carbon steel dominates general construction, automotive, and machinery manufacturing. Its higher initial hardness and tensile strength make it suitable for cutting tools, springs, and structural frameworks. Carbon steel’s easier machinability and lower cost also contribute to its widespread adoption in these sectors.

Tip: When selecting between manganese steel vs carbon steel, engineers should match the material’s properties to the specific demands of the application. For high-impact, abrasive environments, manganese steel offers superior performance. For general construction and precision tools, carbon steel remains the preferred choice.

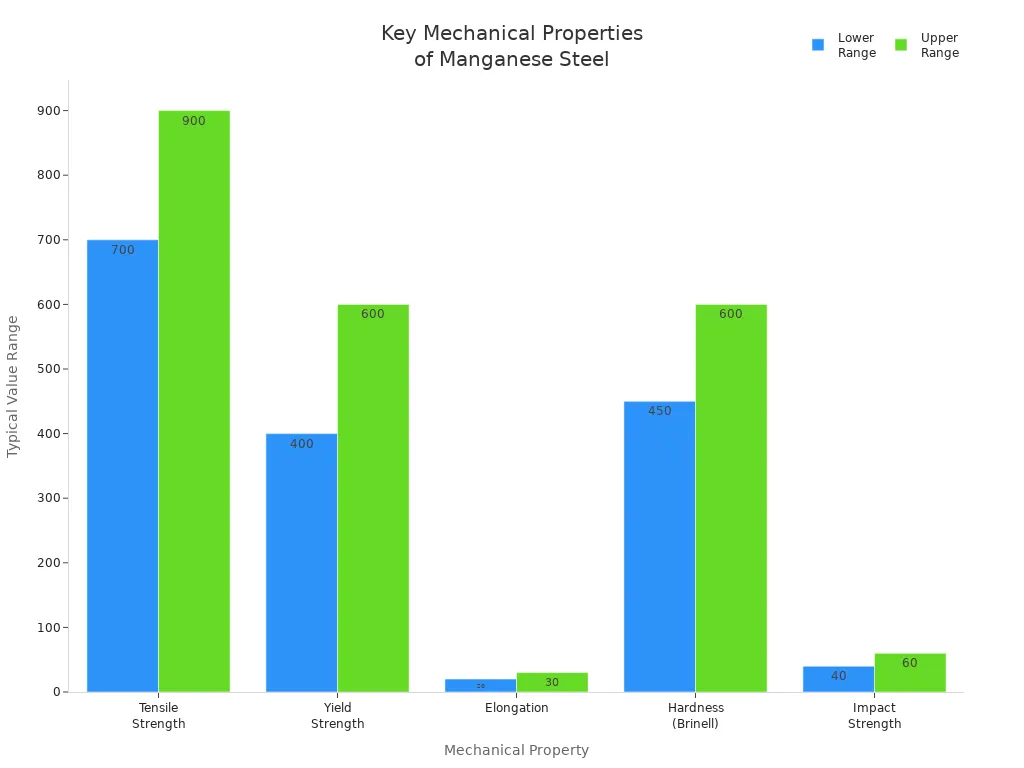

The following chart illustrates the mechanical property ranges for manganese steel, highlighting its suitability for demanding industrial applications:

Manganese steel’s high carbon and manganese content stabilize its austenitic structure, enabling work hardening under impact and deformation. This property enhances wear resistance and toughness, making it ideal for mining, railways, and construction. However, welding manganese steel requires careful heat treatment to avoid cracking, and machining must be performed with caution to prevent premature work hardening.

Composition

Manganese Steel

Manganese steel stands out due to its unique chemical composition. High manganese steel plate typically contains 12% to 14% manganese and about 1% carbon. This high manganese content classifies it as an alloy steel and gives it the name high-manganese steel. The elevated manganese level in manganese steel plate improves hardenability and toughness. It also reduces brittleness, especially when sulfur is present. These properties make high manganese steel plate ideal for demanding environments.

The combination of manganese and carbon in high manganese steel plate leads to exceptional work hardening. When subjected to impact or abrasion, the surface of high manganese steel plate becomes harder, while the core remains tough. This dual nature allows high manganese steel plate to resist wear and absorb shock. Industries often select high manganese steel plate for applications where both toughness and wear resistance are critical.

Note: High-manganese steel also counteracts sulfur-induced brittleness, which further enhances its durability in harsh conditions.

Carbon Steel

Carbon steel relies mainly on its carbon content to define its properties. High carbon steel usually contains between 0.6% and 1.4% carbon, while the manganese content ranges from 0.6% to 1.65%. The properties of high carbon steel change as the carbon percentage increases. Higher carbon levels boost hardness, strength, and wear resistance. However, these gains come at the cost of reduced ductility and machinability.

High carbon steel plate offers excellent initial hardness and tensile strength. Manufacturers use high carbon steel plate for tools, blades, and structural parts that require rigidity. The lower manganese content in high carbon steel means it does not benefit from the same toughness and work hardening as high manganese steel plate. Instead, high carbon steel plate provides stable mechanical properties, making it suitable for precision applications.

Steel Type | Carbon Content (%) | Manganese Content (%) | Key Properties |

|---|---|---|---|

High manganese steel | ~1 | 12-14 | Toughness, work hardening |

High carbon steel | 0.6-1.4 | 0.6-1.65 | Hardness, strength, rigidity |

The variation in chemical composition between high manganese steel plate and high carbon steel plate directly impacts their mechanical properties. High manganese steel plate excels in toughness and resistance to brittleness, while high carbon steel plate offers superior hardness and strength.

Mechanical Properties

Hardness and Wear

Manganese steel plate demonstrates outstanding mechanical properties in abrasive environments. Its high manganese content, ranging from 12% to 14%, gives it a unique work-hardening ability. When subjected to repeated impact or pressure, the surface of high manganese steel plate becomes significantly harder. This transformation results in excellent wear resistance and high impact strength. In contrast, high carbon steel offers good initial hardness but lacks the same work-hardening behavior. Carbon steel provides reliable machinability and weldability, yet it cannot match the abrasion resistance or durability against wear found in manganese steel plate.

Aspect | Manganese Steel | Carbon Steel |

|---|---|---|

Composition | Contains 1% to 14% manganese, carbon, and iron | Primarily iron and carbon (0.03% to 2.0%) |

Properties | High hardness, excellent wear resistance, impact strength, work-hardening behavior | Good machinability, weldability, less wear resistant and impact resistant |

Wear Resistance | Superior in abrasive environments due to work-hardening and toughness | Lower wear resistance, less suitable for severe abrasive wear |

Applications | Railroad tracks, mining equipment, grinding balls, coal pulverizer liners | Construction, automotive, machinery, shipbuilding |

Cost | Generally higher due to alloying and specialized use | More cost-effective due to simpler composition |

Toughness and Impact

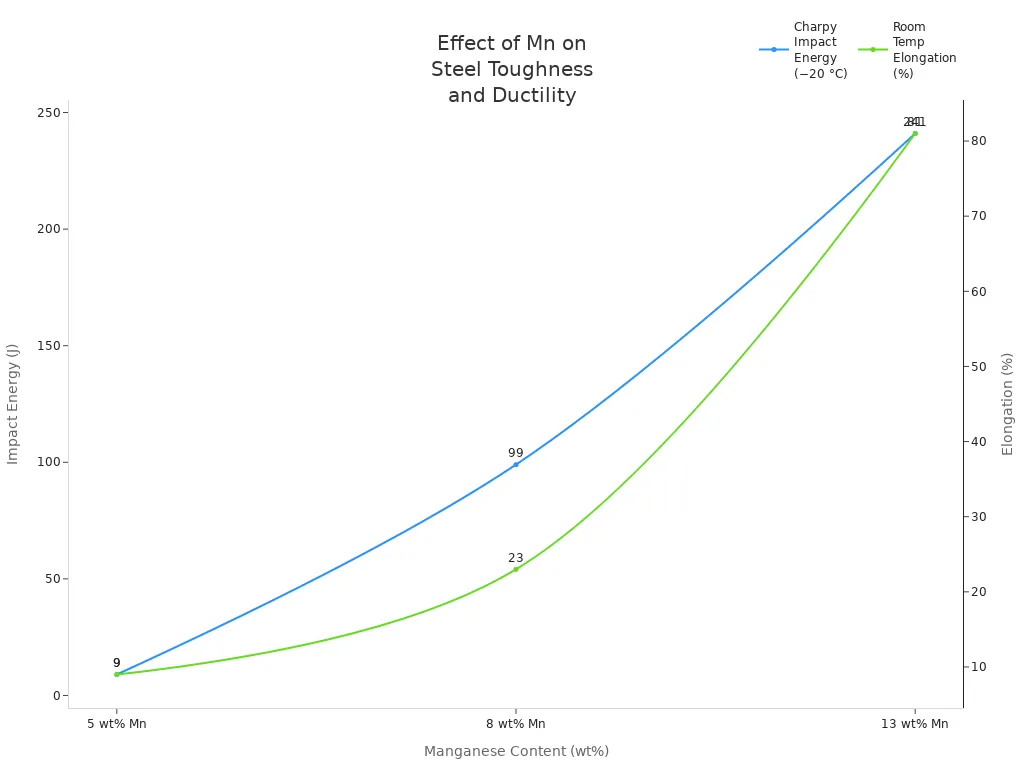

High manganese steel plate stands out for its high impact strength and toughness. As manganese content increases, both impact resistance and ductility improve. Standardized tests show that manganese steel with 13% manganese achieves a Charpy impact energy of 241 J at −20 °C, far surpassing lower manganese grades. This high impact resistance makes manganese steel plate ideal for mining equipment and railroad tracks, where sudden shocks occur frequently. High carbon steel, while strong, does not reach the same level of toughness or impact resistance. Its mechanical properties depend on grain size and heat treatment, but it remains more prone to brittle failure under extreme conditions.

Ductility

Ductility measures a material’s ability to deform without breaking. High manganese steel plate exhibits remarkable ductility, especially as manganese content rises. This property allows it to absorb energy and resist cracking during heavy use. The work-hardening ability of manganese steel plate further enhances its mechanical properties, making it less likely to fail under stress. High carbon steel, while offering strength and rigidity, shows lower ductility. It can become brittle, especially in cold environments or when exposed to corrosive elements. Engineers value the combination of ductility, abrasion resistance, and impact resistance in manganese steel plate for demanding applications.

Applications in 2025

Manganese Steel Uses

Manganese steel continues to play a vital role in industrial applications in 2025. The steel industry remains the largest consumer, using manganese steel and high manganese steel plate for ferroalloy production. These alloys provide essential strength and wear resistance for construction beams, rails, and heavy machinery. Mining companies rely on manganese steel plate for crusher liners and grinding balls, where abrasion resistance and impact strength are critical. Railways use manganese steel for track components, ensuring durability under heavy loads and frequent impacts.

Emerging trends show a growing demand for manganese steel in electric vehicle (EV) batteries. Battery manufacturers use manganese-based chemistries, such as lithium-manganese-iron-phosphate, to achieve cost-effective energy storage with high energy density. Governments and companies invest in domestic battery-grade manganese production, driven by supply chain diversification and environmental regulations. Despite this growth, steelmaking remains the primary application, shaping market dynamics and pricing. Infrastructure upgrades and trade policies also influence manganese steel’s role in global supply chains.

Note: Supply chain disruptions and new carbon taxes may affect the availability and cost of manganese steel for industrial applications.

Carbon Steel Uses

Carbon steel remains a cornerstone in a wide range of applications. The automotive industry, especially electric vehicles, leads the demand for high carbon steel and advanced high-strength steel. Manufacturers use these materials for battery protection, structural safety, and lightweight vehicle frames. Innovations like hot stamping and tailored tempering enhance the strength and wear resistance of carbon steel, supporting next-generation vehicle designs.

Construction sectors in emerging economies depend on carbon steel for beams, reinforcing bars, and structural frameworks. The oil, gas, and renewable energy industries use carbon steel for pipelines, storage tanks, and wind or solar infrastructure. Shipbuilding and marine construction in countries like South Korea rely on high-strength carbon steel for offshore platforms and hulls. Precision manufacturing in Japan uses carbon steel for machinery and impact-resistant components.

In 2025, practical applications for both manganese steel and carbon steel continue to expand. Each material’s unique combination of strength, wear resistance, and abrasion resistance ensures their place in critical industrial applications worldwide.

Production and Cost

Manufacturing

Manufacturers use different processes to produce manganese steel and carbon steel. Manganese steel production requires precise control of temperature and composition. Steelmakers add manganese and carbon to molten iron in electric arc furnaces. They must monitor the cooling rate to maintain the austenitic structure. This process often includes additional alloying elements for improved performance. Workers then cast the steel into molds and perform heat treatment to enhance toughness.

Carbon steel production uses basic oxygen or electric arc furnaces. The process involves melting iron ore and adding carbon. Producers adjust the carbon content to achieve the desired hardness and strength. Carbon steel manufacturing is less complex than manganese steel production. This simplicity allows for higher output and lower costs.

Cost Factors

Several factors influence the cost of manganese steel and carbon steel. Manganese steel costs more due to its high alloy content and specialized production steps. The need for careful heat treatment and quality control increases labor and energy expenses. Supply chain issues, such as manganese ore availability, can also raise prices.

Carbon steel remains more affordable. Its raw materials are widely available, and the production process is efficient. The table below compares key cost drivers:

Factor | Manganese Steel | Carbon Steel |

|---|---|---|

Alloying Elements | High | Low |

Energy Consumption | High | Moderate |

Labor Intensity | High | Low |

Raw Material Cost | Higher | Lower |

Tip: Buyers should consider both initial material cost and long-term performance when selecting steel.

Machinability

Machinability describes how easily a material can be cut, shaped, or drilled. Carbon steel offers good machinability. Workers can cut and weld it with standard tools. This property makes carbon steel popular for construction and manufacturing.

Manganese steel presents challenges during machining. Its work-hardening ability causes the surface to become harder as tools cut into it. This property leads to rapid tool wear and slower processing speeds. Machinists often use carbide-tipped tools and specialized techniques to shape manganese steel. For best results, many manufacturers prefer to cast or forge manganese steel components close to their final shape.

Note: Proper tool selection and cooling methods help improve machinability for both steel types.

Heat Treatment

Manganese Steel

Heat treatment plays a crucial role in optimizing the mechanical properties of manganese steel. Engineers often use intercritical annealing near the Ac1 temperature, typically around 650 °C, to achieve the best balance between strength and ductility. Annealing at approximately 690 °C for 10 minutes stabilizes retained austenite by allowing manganese and carbon to partition within the steel. This process enhances the TRIP effect, which improves mechanical performance and supports the steel’s work-hardening ability. When the annealing temperature exceeds 700 °C, the stability and volume of retained austenite decrease. This change leads to higher tensile strength but reduces ductility, as martensitic transformation becomes more dominant. Careful control of annealing time and temperature ensures the right balance of austenite fraction, grain size, and dislocation density, all of which influence work-hardening.

After annealing, quenching helps retain the optimized microstructure. Some manufacturers also use thermomechanical treatments, such as warm rolling at 200 °C, followed by recovery annealing at 520–550 °C. This method introduces a high density of deformation twins and dislocations, creating an ultrafine microstructure. The result is a steel with excellent work-hardening, high tensile strength, and uniform elongation. The combination of TWIP and TRIP effects during plastic deformation further boosts work-hardening, making manganese steel ideal for high-impact and abrasive environments. Work-hardening remains the defining feature of manganese steel, allowing it to resist wear and absorb shock in demanding applications. The steel’s ability to undergo work-hardening during service extends its lifespan and reliability. Work-hardening also complicates machining, so manufacturers often cast or forge components close to their final shape. Work-hardening ensures that manganese steel maintains superior performance under repeated impact and abrasion. Work-hardening, activated by both mechanical and thermal processes, sets manganese steel apart from other alloys. Work-hardening continues to be the primary reason for its selection in mining, rail, and heavy machinery sectors.

Carbon Steel

Heat treatment for carbon steel focuses on adjusting hardness, strength, and ductility. Common processes include annealing, quenching, and tempering. Annealing softens the steel, refines its grain structure, and improves machinability. Quenching rapidly cools the steel from high temperatures, increasing hardness and tensile strength. Tempering follows quenching to reduce brittleness and restore some ductility. The specific heat treatment sequence depends on the desired properties and the carbon content of the steel.

High carbon steel responds well to these treatments. Quenching and tempering produce a strong, hard microstructure suitable for cutting tools and structural components. Lower carbon steels may require only annealing or normalizing to achieve the right balance of properties. Unlike manganese steel, carbon steel does not exhibit significant work-hardening during service. Its mechanical properties remain stable after heat treatment, making it predictable and easy to machine. Engineers select the heat treatment process based on the application’s requirements, ensuring that carbon steel delivers consistent performance in construction, automotive, and manufacturing industries.

Material Selection

Choosing the Right Steel

Selecting the right steel for industrial or engineering applications in 2025 requires a careful evaluation of mechanical properties, fabrication needs, and environmental conditions. Manganese steel and carbon steel each offer unique advantages, but their suitability depends on the specific demands of the project.

The following table summarizes the most important factors to consider when comparing manganese steel and carbon steel:

Factor/Property | Manganese Steel | Carbon Steel (varies by grade) | Notes on Selection Criteria |

|---|---|---|---|

Hardness & Wear Resistance | Very high (work hardens to ~600 HB) | Moderate to high (depends on grade) | Manganese steel excels in high-impact, high-wear uses |

Toughness | Excellent | Moderate to good | Manganese steel absorbs energy without fracturing |

Corrosion Resistance | Poor (susceptible to rust, pitting) | Generally better (especially stainless grades) | Carbon steel preferred in corrosive environments |

Weldability | Challenging (requires preheat, special filler) | Generally good to excellent | Carbon steel easier to weld, manganese steel needs care |

Machinability | Moderate to difficult | Good to excellent | Carbon steel easier to machine |

Formability | Good but work hardens | Good to excellent | Manganese steel can work-harden, affecting forming |

Heat Resistance | Maintains strength up to ~300°C | Varies, often lower | Manganese steel suitable for moderate heat applications |

Cost | Moderate to high | Generally lower | Carbon steel more cost-effective |

Availability | Moderate | High | Carbon steel widely available |

Engineers often choose manganese steel for applications that demand high wear resistance, toughness, and impact strength. Mining operations use manganese steel in crusher liners because it withstands abrasive wear and repeated impact. Rail transport relies on manganese steel for railway tracks, where durability under heavy loads is essential. Heavy machinery components benefit from the material’s strength and ductility, ensuring reliability in demanding conditions. Metal recycling facilities select manganese steel for shredder blades, taking advantage of its work-hardening and toughness in high-impact environments.

Carbon steel remains the preferred choice when weldability, machinability, corrosion resistance, and cost-effectiveness are priorities. Construction projects, automotive manufacturing, and general machinery production often use carbon steel due to its stable properties and ease of fabrication. Stainless grades of carbon steel provide better corrosion resistance, making them suitable for harsh or wet environments.

Tip: Always match the steel’s properties to the application’s requirements. Consider the expected loads, exposure to abrasion, and the need for work-hardening or corrosion resistance.

Factors for 2025

Material selection in 2025 involves more than just mechanical performance. Market trends, supply chain stability, and fabrication complexity all influence the decision between manganese steel and carbon steel.

Manganese supply faces risks from geopolitical events, environmental regulations, and production disruptions. For example, the South32 Groote Eylandt mine outage has delayed exports until the third quarter of 2025. This situation may cause price volatility and affect the availability of manganese steel for critical applications.

Demand for manganese remains strong in steel production, with additional growth from the electric vehicle battery sector. However, batteries still represent a smaller share of total manganese ore demand.

Oversupply and weak steel demand in China have created price headwinds, but a recovery is expected as global steel demand improves and new battery chemistries increase manganese use.

Efforts to diversify manganese supply chains outside China are ongoing. Investments in high purity manganese sulphate production in the US, Australia, South Africa, and Canada aim to improve supply security. These projects face technical and timing challenges, with operational plants still years away.

Carbon steel continues to offer high availability and stable pricing. Its widespread use in construction, automotive, and infrastructure projects ensures a reliable supply chain. Fabrication with carbon steel remains straightforward, with good weldability and machinability across most grades.

Manganese steel requires specific heat treatment processes, such as annealing, quenching, and tempering, to optimize hardness, toughness, and ductility. Welding manganese steel presents challenges due to its high carbon content and risk of cracking. Preheating and post-weld heat treatment are often necessary. These fabrication complexities contrast with carbon steel, which generally offers easier weldability and machining.

When selecting between manganese steel and carbon steel in 2025, decision-makers should weigh the following:

Required mechanical properties, including strength, toughness, and work-hardening.

Environmental conditions, such as exposure to corrosion or high temperatures.

Fabrication requirements, including welding, machining, and forming.

Cost and availability, considering potential supply chain disruptions.

Long-term performance and maintenance needs for the intended applications.

Note: The right choice balances technical requirements, market conditions, and fabrication capabilities. Regularly review supply chain updates and material specifications to ensure optimal performance in every project.

Manganese steel and carbon steel each serve distinct roles in modern industry. Manganese steel delivers superior strength, wear resistance, and impact durability, making it ideal for mining equipment and heavy-duty machinery. Carbon steel remains cost-effective and widely available, excelling in construction and automotive applications.

Property | Manganese Steel | Carbon Steel |

|---|---|---|

Wear Resistance | Excellent | Moderate |

Impact Resistance | Superior | Moderate |

Cost | Higher | Lower |

Maintenance | Less frequent | More frequent |

For demanding environments, engineers should select manganese steel. For general use and lower budgets, carbon steel offers practical advantages. Decision-makers should balance technical needs with long-term costs and maintenance requirements.

FAQ

What makes manganese steel different from carbon steel?

Manganese steel contains much more manganese, which gives it superior toughness and work-hardening ability. Carbon steel relies on carbon for strength and hardness. Manganese steel resists wear and impact better, while carbon steel offers easier machining and lower cost.

Can you weld manganese steel easily?

Welding manganese steel requires special care. Preheating and using the correct filler metal help prevent cracking. Most fabricators recommend post-weld heat treatment. Carbon steel, by comparison, welds more easily with standard techniques.

Which steel is better for high-impact environments?

Manganese steel performs best in high-impact settings. Its work-hardening property allows it to absorb shock and resist abrasion. Mining, rail, and heavy machinery industries often choose manganese steel for these reasons.

Is carbon steel suitable for outdoor or corrosive environments?

Standard carbon steel rusts when exposed to moisture. For outdoor or corrosive environments, engineers select stainless or coated carbon steel. Manganese steel also lacks corrosion resistance and needs protective coatings.

How does the cost of manganese steel compare to carbon steel?

Manganese steel usually costs more than carbon steel. The higher price comes from alloying elements and complex processing. Carbon steel remains more affordable and widely available for most construction and manufacturing needs.

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.