Executive Summary

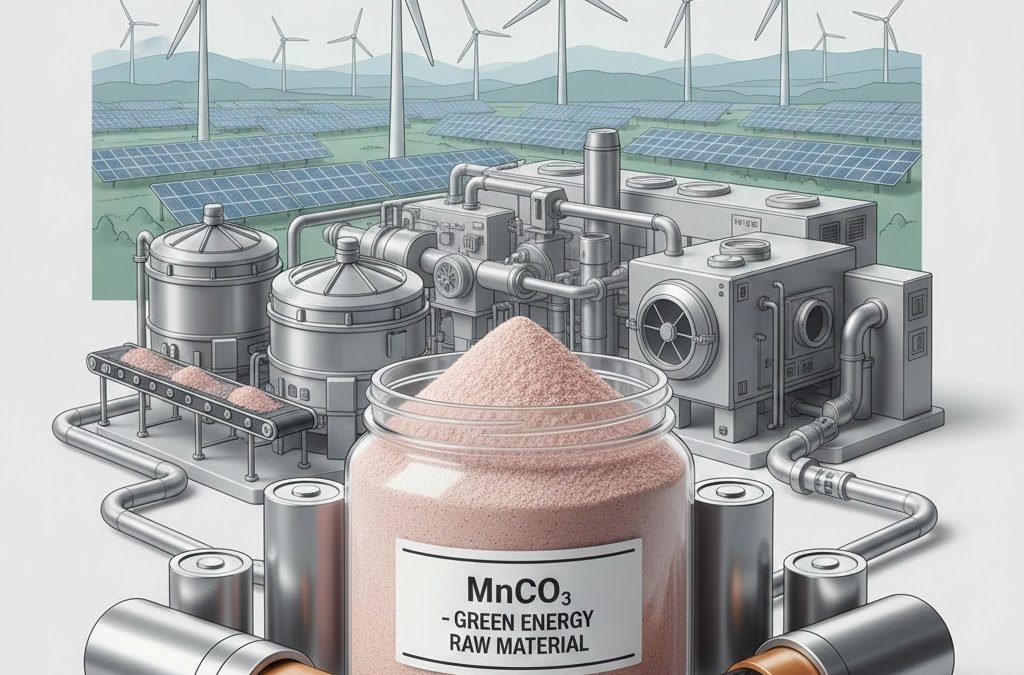

Manganese carbonate plays a critical but often underestimated role in modern green energy solutions, particularly in lithium-ion batteries, energy storage systems, and sustainable materials manufacturing. As a key precursor for battery-grade manganese oxides and manganese sulfate, manganese carbonate directly influences cathode performance, production yield, and long-term battery stability. From an energy transition perspective, manganese-based chemistries enable lower-cost, lower-cobalt, and more environmentally balanced battery systems.

Compared with direct manganese oxide sourcing, manganese carbonate offers better process controllability, lower impurity risk, and improved conversion efficiency. Typical battery-grade manganese carbonate with ≥97.5% purity, controlled particle size, and low heavy metal content supports consistent electrochemical performance, stable calcination behavior, and reduced defect rates. These characteristics make manganese carbonate an essential upstream material for green energy supply chains focused on cost efficiency, scalability, and sustainability.

Technical Background: What Is Manganese Carbonate?

Chemical and Physical Overview

Manganese carbonate (MnCO₃) is an inorganic compound commonly used as an intermediate raw material in the production of manganese oxides and manganese sulfate. It is typically produced via precipitation methods using manganese salts and carbonate sources.

Key physical characteristics include:

Light pink to pale brown powder

Insoluble in water

Decomposes upon heating at ~200–300 °C

Manganese content: ~47–48% (theoretical)

Role in Green Energy Value Chains

Manganese carbonate is not used directly as an active battery material. Instead, it serves as a controlled precursor for:

Electrolytic manganese dioxide (EMD)

Chemical manganese dioxide (CMD)

Battery-grade manganese sulfate (MnSO₄·H₂O)

Lithium manganese oxide (LMO) cathodes

NCM / NMx cathode precursor systems

In green energy manufacturing, precursor quality strongly determines the consistency, yield, and performance of downstream materials.

Why Precursor Quality Matters in Green Energy Applications

Green energy systems demand long cycle life, high energy efficiency, and low failure rates. These requirements place strict constraints on raw material variability.

Poor-quality manganese carbonate can lead to:

Inconsistent calcination reactions

Excessive impurity transfer into cathode materials

Particle morphology defects

Reduced battery cycle stability

Increased scrap rates during cathode production

High-purity manganese carbonate enables tighter process windows and lower environmental waste during manufacturing.

Key Benefits of Manganese Carbonate for Green Energy

1. Purity Level and Electrochemical Stability

Typical purity ranges:

Industrial grade: 93–95% MnCO₃

Battery grade: ≥97.5–99.0% MnCO₃

Higher purity directly reduces non-active residues after calcination.

Impact mechanism:

Fewer inert oxides remain in MnO₂ or MnSO₄

More uniform manganese valence distribution

Reduced localized impedance growth in cathodes

In lithium-ion batteries, manganese-related impurity reduction is associated with:

1–3% improvement in initial discharge capacity

More stable capacity retention after 500 cycles

2. Particle Size Distribution (PSD) and Reaction Kinetics

Typical battery-grade PSD:

D50: 5–10 µm

D90: <20 µm

Uniform particle size improves:

Acid dissolution rate during MnSO₄ production

Thermal decomposition uniformity

Solid-state reaction completeness

Oversized particles can cause incomplete conversion, while ultra-fine powders increase dust loss and handling risks.

Controlled PSD supports higher conversion efficiency and reduces unreacted residue below 0.5%.

3. Moisture and Loss on Ignition (LOI)

Typical requirements:

Moisture: ≤0.5%

LOI (300–500 °C): 31–33%

Excess moisture leads to:

Agglomeration during storage

Inconsistent feed rates

Local overheating during calcination

Stable LOI values indicate predictable carbonate decomposition, which is essential for large-scale, energy-efficient furnace operation.

4. Heavy Metal Impurity Control (Fe, Cu, Ni)

Typical battery-grade limits:

Fe: ≤50–100 ppm

Cu: ≤10–20 ppm

Ni: ≤20–30 ppm

These metals can act as parasitic redox centers in batteries, accelerating electrolyte decomposition.

Impurity-controlled manganese carbonate reduces:

Internal short-circuit risk

Self-discharge rate

Transition metal dissolution in cathodes

Typical Battery-Grade Manganese Carbonate Specifications

| Parameter | Typical Battery-Grade Range | Why It Matters |

|---|---|---|

| Purity (MnCO₃) | ≥97.5–99.0% | Ensures high conversion yield |

| Mn Content | ≥47.5% | Stable stoichiometry |

| D50 Particle Size | 5–10 µm | Controlled reaction kinetics |

| Moisture | ≤0.5% | Storage and dosing stability |

| LOI | 31–33% | Predictable calcination |

| Fe Content | ≤100 ppm | Protects cycle life |

| Cu Content | ≤20 ppm | Prevents micro-shorts |

Impact on Green Energy Battery Performance (KPIs)

High-quality manganese carbonate influences several measurable KPIs:

Initial capacity: +1–3% compared with low-purity precursors

Capacity retention (500 cycles): +2–5% improvement

Cathode yield: 1–2% reduction in off-spec batches

Batch consistency: Lower standard deviation in Mn valence state

Manufacturing scrap rate: Reduced by up to 30% in some plants

These improvements translate into lower per-kWh manufacturing costs and reduced environmental waste.

Quality Control and Testing Methods

Reliable green energy supply chains require transparent quality control.

Common COA Test Items

MnCO₃ purity

Mn content

Moisture

LOI

PSD

Heavy metal impurities

Analytical Methods

ICP-OES / ICP-MS: Fe, Cu, Ni, Pb, Zn

Laser diffraction: Particle size distribution

Thermogravimetric analysis (TGA): LOI behavior

Karl Fischer or oven method: Moisture content

Representative sampling from each batch is critical for data reliability.

Purchasing and Supplier Evaluation Considerations

Grade Differentiation

Industrial grade: pigments, fertilizers

Battery grade: lithium-ion, alkaline, zinc-carbon

Electronic grade: stricter impurity limits

Using industrial-grade material in battery production increases failure risk.

Packaging and Storage

25 kg moisture-barrier bags

Palletized with stretch wrap

Stored below 30 °C, <60% RH

Poor packaging can raise moisture by >0.5% within 3 months.

Common Sourcing Risks

Unstable PSD between batches

Hidden heavy metal contamination

Incomplete COA data

Inconsistent production methods

Supplier process transparency is critical.

Frequently Asked Questions (FAQ)

What purity is required for green energy battery applications?

Typically ≥97.5% MnCO₃.

What particle size is recommended?

D50 between 5–10 µm for stable processing.

Why is LOI important?

It reflects decomposition predictability during calcination.

How are heavy metals controlled?

Through raw material selection and ICP-based monitoring.

Is manganese carbonate more sustainable than direct MnO₂ sourcing?

Yes, it offers higher process efficiency and lower waste generation.

Can industrial-grade material be upgraded?

Often not cost-effective due to impurity entrapment.

Final Practical Checklist for Buyers and QA Teams

Confirm MnCO₃ purity ≥97.5%

Verify PSD consistency (D50, D90)

Review Fe, Cu, Ni ppm levels

Check moisture and LOI stability

Request batch-level COA and test methods

Audit supplier production process

Validate storage and packaging standards

Conclusion:

Manganese carbonate supports green energy solutions not through marketing appeal, but through measurable improvements in precursor consistency, battery performance, and manufacturing efficiency. For battery manufacturers and energy material producers, selecting the right manganese carbonate grade is a technical decision with long-term cost, sustainability, and reliability implications.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.