Executive Summary

Manganese carbonate (MnCO₃) is one of the most widely used precursors for producing manganese oxides, including MnO, Mn₃O₄, and MnO₂, in battery, ceramic, catalyst, and chemical industries. Its importance lies in its controlled decomposition behavior, high conversion efficiency, and impurity management capability during thermal processing. Compared with manganese dioxide or manganese sulfate routes, manganese carbonate offers lower calcination temperatures (350–900 °C), predictable phase transformation, and reduced sulfur or chlorine residue risks. For battery cathode producers and industrial material processors, precursor quality—such as purity ≥97.5%, controlled particle size (D50 5–15 µm), and low heavy-metal content—directly affects oxide phase purity, electrochemical stability, and batch-to-batch consistency.

.

1. Technical Background: What Is Manganese Carbonate?

Manganese carbonate (MnCO₃) is a light pink to off-white crystalline powder, typically produced via precipitation (wet process) or solid-state reaction (dry process). It serves as a key intermediate in manganese chemistry because it decomposes cleanly into manganese oxides under controlled thermal conditions.

1.1 Role in Industrial and Battery Applications

Manganese carbonate is commonly used as a precursor for:

Manganese monoxide (MnO) – battery cathode additives, ferrites

Trimanganese tetroxide (Mn₃O₄) – ceramic pigments, catalysts

Electrolytic manganese dioxide (EMD) feedstock

Chemical manganese dioxide (CMD) production

Glass, ceramic, and catalyst formulations

In lithium battery and primary battery manufacturing, precursor stability and impurity control strongly influence the final oxide’s electrochemical activity and structural integrity.

1.2 Why Precursor Quality Matters

Unlike post-purification of oxides, precursor impurities often carry through calcination. Elements such as Fe, Cu, Ni, and Zn can alter crystal growth kinetics, promote unwanted phases, and negatively impact cycle life or discharge stability.

.

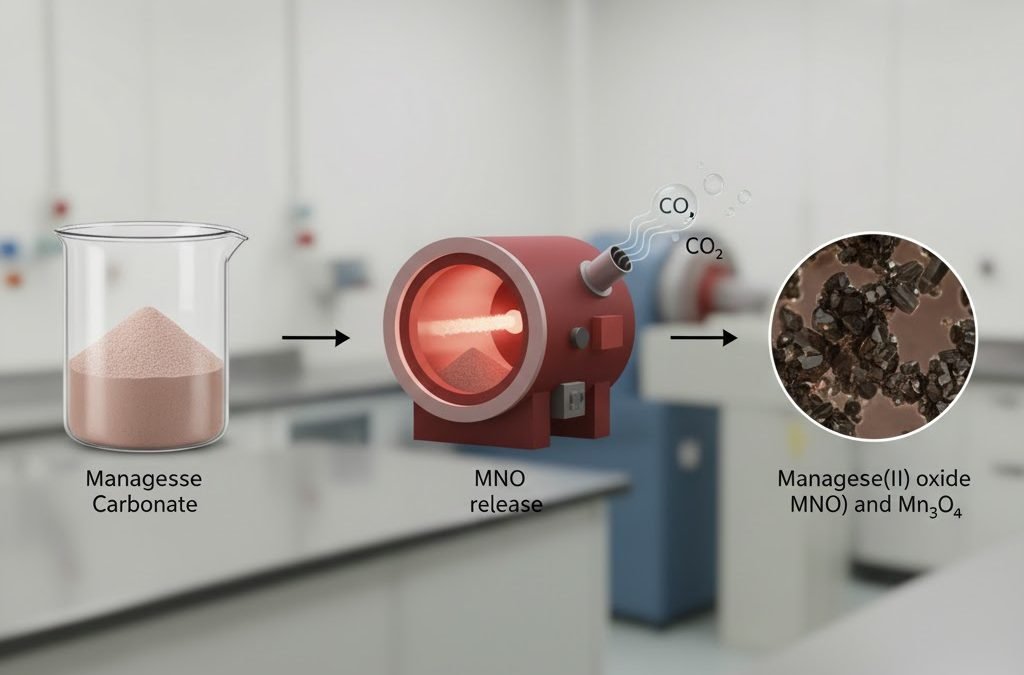

2. Thermal Decomposition Mechanism of Manganese Carbonate

Manganese carbonate decomposes according to the following general reaction:

2.1 Decomposition Temperature Range

Onset temperature: ~300–350 °C

Complete decomposition: 450–500 °C (air or inert atmosphere)

Further oxidation: >600 °C (MnO → Mn₃O₄ or Mn₂O₃ depending on oxygen partial pressure)

This relatively low decomposition temperature allows manufacturers to control oxide phase formation without excessive grain growth.

3. Key Benefits of Manganese Carbonate as a Precursor

3.1 High Chemical Conversion Efficiency

Typical MnCO₃ to MnO conversion yields exceed 98% under optimized calcination conditions. The absence of sulfur, chloride, or nitrate anions reduces post-treatment requirements.

Impact:

Lower material loss

Higher usable oxide yield per metric ton of precursor

3.2 Purity Control and Phase Stability

Battery-grade manganese carbonate typically meets:

MnCO₃ purity: ≥97.5–99.0%

Total metallic impurities: <500 ppm

Low impurity levels reduce secondary phase formation during calcination, improving oxide crystallinity.

Engineering Principle:

High precursor purity → uniform nucleation → consistent oxide phase composition

3.3 Particle Size Uniformity and Reaction Kinetics

Recommended precursor particle size:

D50: 5–15 µm

D90: <30 µm

Smaller, uniform particles ensure:

Faster CO₂ release

Lower internal diffusion resistance

Reduced residual carbonate content (<0.3%)

3.4 Moisture and LOI Stability

Typical specifications:

Moisture: ≤0.5%

LOI (Loss on Ignition): 31–34% (theoretical MnCO₃ value ≈34.7%)

Stable LOI indicates consistent carbonate composition and predictable decomposition behavior.

3.5 Flexible Oxide Phase Engineering

By adjusting atmosphere and temperature, manganese carbonate can produce:

| Calcination Condition | Resulting Oxide |

|---|---|

| 450–500 °C, N₂ | MnO |

| 600–750 °C, air | Mn₃O₄ |

| >800 °C, O₂-rich | Mn₂O₃ |

This flexibility is critical for multi-application oxide producers.

4. Typical Battery-Grade Manganese Carbonate Specification

| Parameter | Typical Battery-Grade Range | Why It Matters |

|---|---|---|

| MnCO₃ purity (%) | ≥97.5–99.0 | Determines oxide phase purity |

| Mn content (%) | ≥45.5 | Indicates effective carbonate composition |

| Particle size D50 (µm) | 5–15 | Controls calcination kinetics |

| Moisture (%) | ≤0.5 | Prevents agglomeration |

| LOI (%) | 31–34 | Ensures predictable decomposition |

| Fe (ppm) | ≤100 | Avoids catalytic side reactions |

| Cu (ppm) | ≤20 | Prevents electrochemical instability |

| Ni (ppm) | ≤20 | Improves cycle stability |

5. Impact on Manganese Oxide Performance

5.1 Phase Purity and Crystal Structure

Using high-purity manganese carbonate results in:

≥99% target oxide phase

Reduced secondary oxide formation

Controlled grain size (0.5–2.0 µm after calcination)

5.2 Electrochemical Performance (Battery Applications)

For manganese oxides derived from battery-grade MnCO₃:

Initial discharge capacity improvement: 3–6%

Capacity retention after 300 cycles: +5–10%

Internal resistance reduction: 8–12%

These improvements stem from reduced impurity-driven lattice distortion.

5.3 Manufacturing Yield and Consistency

Stable precursor quality reduces:

Batch rejection rates

Calcination temperature variability

Over-oxidation risks

Yield improvements of 2–4% are commonly observed in continuous rotary kiln systems.

6. Quality Control and Testing Methods

6.1 Certificate of Analysis (COA) Items

Standard COA for manganese carbonate should include:

MnCO₃ content

Mn %

Moisture

LOI

Particle size distribution

Heavy metals (Fe, Cu, Ni, Zn)

6.2 Analytical Methods

| Parameter | Test Method |

|---|---|

| Mn, Fe, Cu, Ni | ICP-OES / ICP-MS |

| Particle size | Laser diffraction |

| Moisture | Oven drying at 105 °C |

| LOI | 950 °C ignition |

| Phase composition | XRD (optional) |

Sampling should follow ISO 3165 or equivalent bulk chemical sampling principles.

7. Purchasing and Supplier Evaluation Considerations、

7.1 Grade Differentiation

Industrial grade: ceramics, fertilizers

Battery grade: cathodes, Mn oxides

Electronic grade: high-purity specialty oxides

Battery and oxide producers should avoid industrial-grade material due to higher Fe and moisture levels.

7.2 Packaging and Storage

Recommended packaging:

25 kg multi-layer paper bags with PE liner

1 MT jumbo bags with moisture barrier

Storage conditions:

Dry, <60% RH

Avoid prolonged exposure to CO₂-rich environments

7.3 Common Sourcing Risks

Inconsistent wet-process precipitation control

High chloride residues from poor washing

Unstable PSD across batches

8. Frequently Asked Questions (FAQ)

Q1: What purity of manganese carbonate is required for oxide production?

A: ≥97.5% MnCO₃ is recommended for controlled oxide phase formation.

Q2: What particle size is ideal for calcination?

A: D50 between 5–15 µm ensures uniform decomposition.

Q3: Why is LOI important?

A: LOI reflects carbonate integrity and predicts CO₂ release behavior.

Q4: Can industrial-grade MnCO₃ be used?

A: It increases impurity risk and reduces oxide consistency.

Q5: How are heavy metals controlled?

A: Through raw material selection, controlled precipitation, and ICP testing.

9. Practical Checklist for Buyers and Engineers

✔ Confirm MnCO₃ purity ≥97.5%

✔ Verify Fe ≤100 ppm for battery use

✔ Review PSD consistency (D50, D90)

✔ Check LOI stability across batches

✔ Request full COA with ICP data

✔ Audit supplier calcination experience

Conclusion:

Manganese carbonate remains one of the most technically reliable and economically efficient precursors for manganese oxides. When produced under controlled specifications, it enables predictable phase engineering, stable electrochemical performance, and high manufacturing yields across battery and industrial applications.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.