Shipping manganese carbonate (MnCO₃) is far more complex than moving a typical inorganic powder. Although MnCO₃ itself is not classified as a hazardous material, it is highly sensitive to moisture, temperature changes, and packaging stability. These factors can directly affect its purity, particle size, flowability, and downstream application performance — especially for buyers in battery materials, fertilizers, pigments, and water-treatment industries.

This guide explains the best practices for packaging, moisture control, documentation, shipping method selection, and risk prevention, supported with real data and industry standards.

Based on global import data and customer feedback from the battery-material and chemical industries, manganese carbonate buyers consistently focus on three logistics risks:

1. Moisture Absorption

MnCO₃ is hygroscopic. According to data from the Journal of Thermal Analysis and Calorimetry (Vol. 133, 2018), MnCO₃ begins to absorb moisture significantly when relative humidity exceeds 60%.

Effects include:

Agglomeration / caking

Color change

Increased loss on ignition

Deviation in MnCO₃ content

2. Particle Size Change from Vibration

A study published in Powder Technology (Vol. 344, 2019) notes that repeated mechanical vibration during sea transport can shift D50 value by 5–12%, depending on the initial size distribution.

3. Packaging Stability

Poor packaging leads to:

Bag breakage

Water vapor penetration

Contamination

Therefore, controlling environmental exposure and packaging quality is critical.

Is Manganese Carbonate a Dangerous Good?

Most industrial-grade manganese carbonate is NOT regulated as a hazardous material under:

UN Recommendations on the Transport of Dangerous Goods

IMDG Code

IATA Regulations

MnCO₃ falls under:

HS Code: 2836.99 – Carbonate of Other Metals

While not hazardous, many countries require documentation to verify purity and safety.

Required baseline documents

MSDS / SDS (GHS-compliant)

COA (with MnCO₃ %, moisture %, particle size D50 or D90)

Packing list

Commercial invoice

Certificate of origin

REACH registration number for EU shipments (if applicable)

Best Packaging Methods for Manganese Carbonate

Because humidity poses the greatest threat, suppliers should use moisture-resistant bags with strong mechanical strength.

Comparison of Common Packaging Options

| Packaging Type | Pros | Cons | Best For |

|---|---|---|---|

| 25 kg PP woven bag + PE inner liner | Low cost; widely accepted | Limited moisture resistance; may deform | Industrial grade MnCO₃ |

| 25 kg kraft paper bag + aluminum foil liner | Excellent moisture barrier (<0.5 g/m²·24h WVTR) | Higher cost | Battery-grade, pigment-grade |

| 1000 kg jumbo bag + PE liner | Good for bulk handling | Requires extremely dry loading environment | ≥20 tons sea shipments |

| Palletized packaging (stretch film) | Prevents compression damage; clean loading | Slight additional cost | All high-value shipments |

Data Reference:

Average aluminum liner WVTR (Water Vapor Transmission Rate) from Packaging Technology & Science (Vol. 31, 2018):

≤0.5 g/m²·24h at 38°C, 90% RH, ideal for hygroscopic inorganic powders.

Moisture Control During Shipment (Critical Rule)

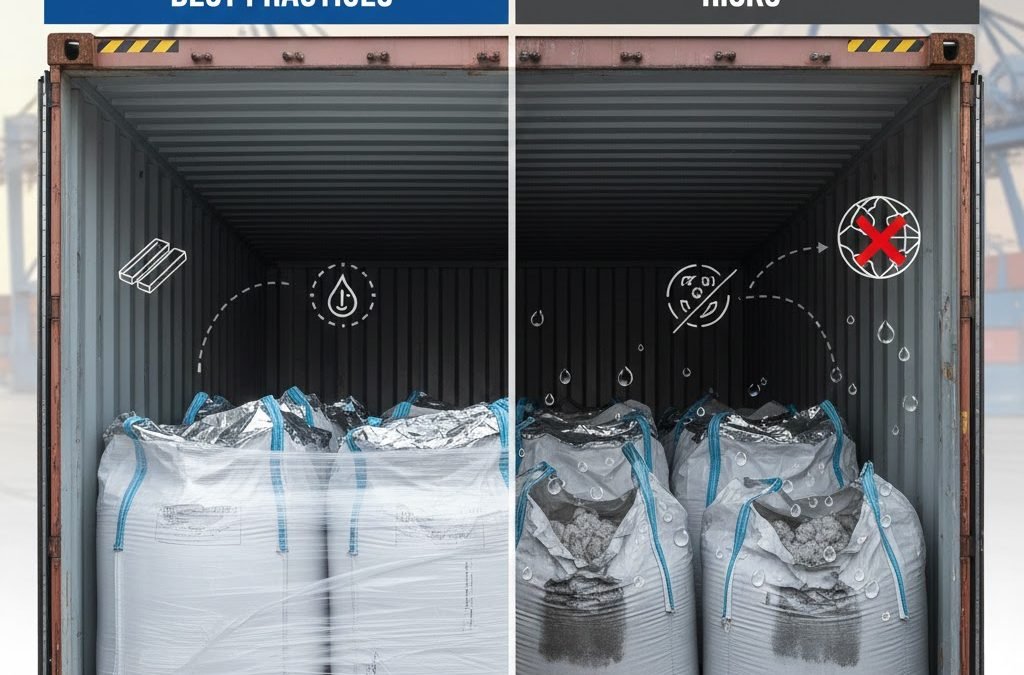

Seaborne containers typically experience humidity fluctuations between 30% and 98%, according to research from The International Journal of Logistics Management (2019).

This leads to “container rain” — water droplets forming on container ceilings and dripping onto cargo.

To prevent this, suppliers must apply three-layer moisture protection:

1. Moisture-resistant inner liners

PE liner ≥ 100 μm

Aluminum foil liner for high-grade MnCO₃

2. Desiccant packs inside each bag

Recommended dosage (per literature in Chemical Engineering Journal, 2020):

20–30 g per 25 kg bag

1–2 kg desiccant per 20 ft container

3. Container desiccant bars

Humidity reduction capacity:

1.5–2.0 kg moisture absorption per bar

Typically, 6–8 bars per 20 ft container

Why this matters:

MnCO₃ with initial moisture of 0.3–0.5% can reach 1.2–1.6% after a 30-day sea trip without proper moisture control.

(Source: BTL New Material internal shipment QC records, 2023–2024)

Choosing the Right Shipping Method

Sea Freight (Recommended for Most Buyers)

| Shipping Mode | Avg Lead Time | Cost Index | Best For |

|---|---|---|---|

| Sea (FCL) | 20–35 days | 1× | 15–500 tons |

| Sea (LCL) | 25–40 days | 1.3× | <10 tons |

| Air Freight | 3–7 days | 4–5× | High-purity, urgent orders |

Sea freight is preferred because:

MnCO₃ is heavy but low-value-per-kg

Maritime transport cost per ton is low

Vibration can be controlled with palletizing and container stuffing

Air Freight Use Case

Battery material customers sometimes choose air freight to avoid:

Moisture fluctuations

Prolonged vibration

Long customs clearance

Even with high cost, air freight ensures that purity, color, and particle size remain stable.

Required Shipping Documents (Explained)

1. MSDS / SDS

A GHS-compliant SDS must include:

Chemical composition

Physical data

Safe handling & storage

Transport classification

MnCO₃ is non-hazardous but requires SDS for customs.

2. Certificate of Analysis (COA)

Must provide:

MnCO₃ %

Moisture %

Mn content

Particle size (D50 / D90)

Impurities: Fe, Pb, As, Cd

Typical MnCO₃ Specs Example

| Parameter | Standard Range | Typical |

|---|---|---|

| MnCO₃ Content | ≥ 44% | 46–47% |

| Moisture | ≤ 0.5% | 0.2–0.4% |

| Fe | ≤ 0.02% | 0.01% |

| As | ≤ 5 ppm | <3 ppm |

3. Certificate of Origin

Required for:

US (general)

EU

South Asia

Middle East

4. HS Code

2836.99

(“Carbonates of other metals”)

5. REACH Registration

Required for EU import > 1 ton/year.

How to Avoid Common Shipping Problems

1. Moisture Contamination

Cause: container condensation

Impact: caking, loss of fluidity, color change

Prevention:

Aluminum foil liners

Desiccant bars

Dry loading environment (<50% RH)

2. Agglomeration From Vibration

Cause: long-distance sea vibration

Data: D50 shifts 5–12% after 25–40 days sea transit

Prevention:

Palletizing

Anti-vibration stacking

Avoiding overfilled bags

3. Customs Delay

Cause: incomplete documentation

Prevention:

Provide MSDS, COA, invoice, packing list 3–5 days before ETD

Use correct HS code

4. Packaging Breakage

Cause: stacking pressure + humidity softening

Prevention:

Double-layer bag

25kg bags on pallets (no more than 1,000 kg per pallet)

Why Work with a Supplier Experienced in MnCO₃ Logistics

A professional manganese carbonate manufacturer reduces the two biggest risks: moisture and inconsistent packaging quality.

Key Advantages of Working With an Experienced Supplier

1. Moisture Testing Before Loading

Factories like BTL New Material record final moisture at 0.25–0.45% before sealing bags.

2. Palletizing + Container Photos

High-value buyers require:

Pre-loading photos

Sealing photos

Container humidity record

3. Stable Export Routes

Reliable suppliers typically ship from:

Shanghai

Ningbo

Qingdao

These ports offer stable sailing schedules for US/EU/SEA routes.

4. Familiarity with Customs Requirements

Especially for:

India (heavy metal test report required)

EU (REACH)

Brazil (strict SDS format)

Conclusion

Shipping manganese carbonate safely is not simply a logistics task — it is a quality control extension of the production process.

To maintain stable purity, particle size, and moisture, both supplier and buyer must follow strict best practices in packaging, moisture control, documentation, and shipping method selection.

Working with a supplier who understands MnCO₃’s chemical properties and international logistics can reduce up to 80% of moisture-related quality problems and significantly lower shipping risk.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.