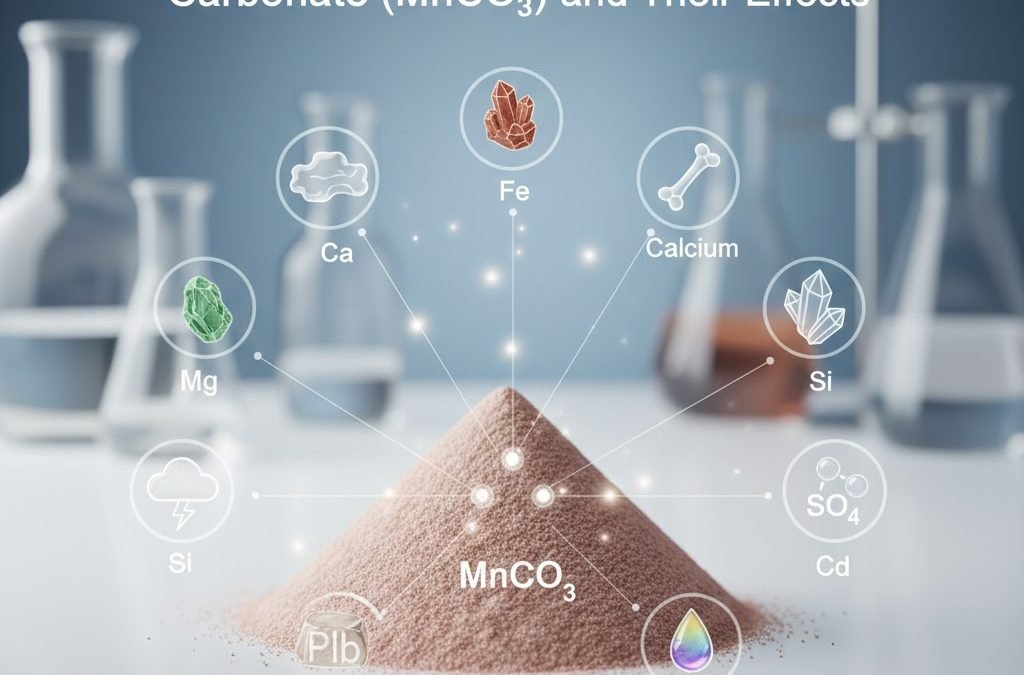

Manganese carbonate (MnCO₃) is a widely used chemical compound. It appears as a light‑brown or pinkish powder (or sometimes crystalline form), and it serves as a precursor for many manganese materials: manganese oxides, salts, catalysts, ceramics pigments, glass additives, and more.

Because MnCO₃ is often used in sensitive downstream applications — like battery materials, high‑quality ceramics or glass, chemical reagents, or catalysts — the purity of MnCO₃ matters a lot. Small amounts of “impurities” (other elements or compounds mixed in) can change final product performance.

In this article, we discuss: what impurities are commonly found in MnCO₃, typical impurity levels (with real data), how these impurities affect various applications, and what measures manufacturers or buyers can take to control impurity levels.

Common Impurities in Manganese Carbonate

Below are some of the most common impurities found in commercially available MnCO₃ — along with typical concentration ranges (when available). The values come from publicly available technical datasheets for MnCO₃ from different suppliers.

| Impurity / Contaminant | Typical Level / Specification Range* | Notes / Remarks |

|---|---|---|

| Manganese (Mn) content (i.e., assay) | ≥ 44.0% (some specs 43.5–44.5%) | This indicates the main active component; rest is impurities + carbonate. |

| Iron (Fe) | ≤ 0.05% (some “technical grade”) ; high purity grades: ≤ 0.002% (~ 20 ppm) | Iron is one of the most common metallic impurities. |

| Calcium (Ca) | ≤ 0.05% in some specifications | May be introduced from raw ore or processing residue. |

| Magnesium (Mg) | Often controlled at low levels; e.g. some high‑purity MnCO₃: Mg ≤ 0.01% (≈ 100 ppm) | Like Ca, from ore or processing water/minerals. |

| Silicon dioxide (SiO₂) or “silica” | Some grades list SiO₂ ≤ 0.04% | Source often is silicate minerals mixed in raw ore. |

| Chloride (Cl⁻) | ≤ 0.01–0.05% depending on spec | Could come from processing chemicals, washing, or salt residue. |

| Sulfate (SO₄²⁻) / Sulfates | Many specs limit sulfate to ≤ 0.5% or 0.6% max, depending on grade. | Residual sulfates may come from acid leaching or ore beneficiation. |

| Heavy metals (Pb, Cd, Zn, etc.) | For high‑purity MnCO₃ some suppliers list Pb, Cd, Zn, Cu etc. under 10–100 ppm range. E.g. one datasheet shows Fe ≤ 0.0010% (≈ 10 ppm), Zn ≤ 0.002% (≈ 20 ppm) | Heavy metal impurities can be critical for sensitive applications. |

* “Typical Level / Specification Range” refers to values given in publicly available MnCO₃ technical data sheets or supplier specs.

From these data we see that “technical‑grade” MnCO₃ may tolerate iron up to 0.05%, while “high‑purity” grades push many impurities down into parts‑per‑thousand (ppt) or parts‑per‑million (ppm) levels.

Effects of Impurities on Different Applications

Why does impurity level matter? Depending on how MnCO₃ will be used, impurities can cause different problems. Below we outline typical applications and how impurities affect them.

Battery Materials (e.g. precursor for manganese oxide, cathode materials)

Many MnCO₃ are used as precursors for manganese oxides (e.g. for lithium manganese oxides) or other battery‑grade manganese compounds. For these uses, metallic impurities such as Fe, Ca, Mg, Zn can end up in the final oxide or salt, and affect electrochemical properties. For example, a recent study on cathode precursors for Ni–Co–Mn (NCM) battery materials showed that cationic impurities (Ca, Zn, Mg, Fe) in manganese source were co‑precipitated into the precursor — though in that case the authors found surprisingly minor effect on the final cell performance under their conditions.

However, other studies show that even small iron impurities at the ppm level in manganese‑based oxide materials can impair the structural stability of lithium‑manganese‑oxide cathodes, accelerate metal dissolution under cycling, and lead to capacity fading.

In short: for battery applications, high purity MnCO₃ with minimal Fe, Ca, Mg, and other metallic contaminants is strongly preferred.

Chemical Processing, Catalysts, Salts

When MnCO₃ is used to produce manganese salts, oxides, or catalysts, impurities such as sulfate, chloride, silicate may interfere with reactions: they can precipitate unwanted by‑products, introduce insoluble residues, or poison catalyst activity. For example, residual sulfate may remain through precipitation or conversion, or chloride may cause corrosion or unwanted side‑reactions.

If heavy metals (e.g. lead, cadmium) are present, toxicity and regulatory compliance become issues — especially for catalysts used in industrial chemical production, or salts destined for regulated markets.

Ceramics, Glass, Pigments

In pigments, ceramic glazes, or glass coloring, manganese carbonate appears as a colorant or flux. Impurities like iron, calcium, magnesium, silica can alter color, melting point, opacity, or the uniformity of glaze. For example, iron may tint the final color, or cause discoloration; silica may change melting behavior or cause cloudiness in glass or glaze.

Also, chloride or sulfate residues may produce defects (bubbles, inclusions) in glass or ceramics during firing.

Environmental and Safety Concerns (Raw Ore / Mining Context)

If MnCO₃ is produced from natural ore (e.g. via processing of manganese ore), impurities like lead, cadmium, arsenic might pose environmental or health hazards if not properly removed — particularly for waste streams, tailings, or if acid leaching is used. Some reviews of natural ore processing show that rhodochrosite (a natural MnCO₃ mineral) deposits can contain heavy metals among impurities.

Even in processed MnCO₃, residual heavy metals may be present if the purification is insufficient — which becomes a concern for disposal, waste management, or use in regulated products.

Case Studies & Real‑World Examples

To make these concepts more concrete, here are a couple of real examples or data‑driven cases that show impurities’ impact.

Example 1: High‑Purity MnCO₃ Supplier Specification

One supplier of high‑purity manganese carbonate lists the following typical quality: Mn content 44.25%, sodium 0.005%, potassium 0.002%, magnesium 0.004%, calcium 0.003%, iron 0.0010%, zinc 0.0011%, copper 0.0001%, lead 0.0005%, chloride 0.0005%, sulfate up to 0.5%.

This high‑purity specification means major metallic impurities are controlled at the level of ~ 10–100 ppm, which is suitable for sensitive applications (battery precursors, chemical reagents, high‑grade ceramics).

Example 2: Impact of Impurities in Battery Cathode Precursors

In a 2023 research article, researchers used manganese source containing impurities (Ca, Zn, Mg, Fe) to prepare precursors for NCM811 cathode (nickel–cobalt–manganese) materials. They found these impurities co‑precipitated into the precursors. However, under their specific conditions, the impurities had “surprisingly minor” effect on the final battery cell performance.

This shows that under some processing conditions, minor impurities might be tolerable — but this depends heavily on the manufacturing process, purification steps after precipitation, and final material specifications.

How to Control Impurities — Best Practices for Suppliers and Buyers

Given the importance of impurity control, here are common strategies (or how a supplier like you can emphasize to clients) to ensure high‑quality MnCO₃:

Raw material selection: choose high-grade manganese ore, free of excessive silicates, heavy‑metal minerals, or gangue. Low-impurity ore reduces the burden on purification downstream.

Optimized processing & purification: use controlled leaching, precipitation, and washing steps to remove silicates, sulfates, chlorides, and dissolve unwanted elements. Some patented methods use acid leaching and precipitation to produce high-purity MnCO₃ from ore.

Strict quality control and testing: use analytical methods (ICP-OES / ICP-MS, titration, insoluble matter tests) to monitor levels of Fe, Ca, Mg, Na, heavy metals, sulfate/chloride residues and insolubles. Provide detailed spec sheets (e.g. controlling Fe ≤ 0.002%, heavy metals under 10–100 ppm) to customers.

Proper storage and packaging: prevent contamination during storage; avoid exposure to moisture or acidic environment that may cause oxidation or interaction. Use sealed bags, liners, and proper labeling. Many high‑purity MnCO₃ suppliers highlight packaging and storage conditions.

Tailored grades for different applications: offer different grades of MnCO₃: “industrial/technical grade” for general uses, and “battery‑grade / high‑purity grade” for sensitive applications (batteries, chemicals, pigments). Provide clear spec sheets for each.

Why Purity Matters — Summary of Key Risks from Impurities

Performance degradation: In battery materials, impurities (especially metal ions) can degrade electrochemical stability, cause unwanted side‑reactions, or accelerate capacity fade.

Product defects or variability: In ceramics, glass, pigments — impurities can lead to color changes, defects, inclusions, inconsistent melting/processing behavior.

Chemical inefficiency or hazards: In chemical synthesis or catalyst production, impurities may reduce yield, poison catalysts, or introduce heavy metal hazards.

Regulatory / health / environmental risks: Heavy metals (lead, cadmium, etc.) or high sulfate/chloride residues pose environmental disposal or safety issues.

Loss of trust / reputation for supplier: If a buyer receives MnCO₃ that underperforms due to impurities, this damages supplier’s reputation.

Recommendation & Best Use Cases — What Buyers Should Ask For

If you are a buyer looking for MnCO₃, here is what you should ask your supplier (or what you should provide if you are a supplier):

Request a detailed specification sheet with Mn assay and detailed impurity limits: Fe, Ca, Mg, Si, Na/K, chloride, sulfate, and heavy metals (Pb, Cd, Zn, etc.).

For sensitive applications (battery, high‑grade chemicals, pigments), insist on high‑purity grade (impurities in ~ ppm range) rather than general industrial grade.

Ask for analytical reports (ICP‑OES or ICP‑MS) rather than just spec declarations.

Confirm particle size distribution and whether there is any insoluble or acid‑insoluble matter (residue), since that may indicate contamination.

Ensure proper packaging and storage, to avoid contamination during transport or shelf storage.

If you are a supplier (like you), you can emphasise: raw‑material control, purification steps, QC testing, stable packaging — to build trust and position your MnCO₃ as “battery‑grade / high‑purity”.

Challenges / Limitations & What Is Not Always Known

Incomplete public data: Although many MnCO₃ suppliers provide specs, not all publish full impurity breakdowns (for example, trace heavy metals, or detailed silicate analysis). This makes it hard for buyers to fully assess risk unless the supplier gives test certificates.

Variable ore sources: If raw ore comes from different mining regions, impurity profile may vary (silicates, heavy metals, gangue minerals) — so consistent quality requires tight raw material control.

Processing trade‑offs: More purification (washings, acid leaching) increases cost and production complexity. Some downstream users may accept “technical‑grade” MnCO₃ if performance is less critical.

Downstream processing effect: Even if MnCO₃ is high purity, downstream processing (oxide synthesis, doping, mixing) may re‑introduce impurities or cause contamination. Purity of final product depends on entire supply chain.

Conclusion

Manganese carbonate (MnCO₃) is a flexible and widely used raw material for many industries — from ceramics and pigments to catalysts and battery materials. But the purity of MnCO₃ matters greatly. Common impurities (iron, calcium, magnesium, silicates, chlorides, sulfates, heavy metals) can affect final product performance, quality, safety, and stability.

Public specifications from top suppliers show that high‑purity MnCO₃ can achieve manganese assay around 44%, with major impurities controlled at ppm levels. As a supplier (or buyer), focusing on raw material selection, optimized purification, rigorous QC testing, proper packaging and offering clear spec sheets can make the difference between “commodity raw material” and “high‑grade raw material.”

For sensitive applications — especially battery materials, chemical reagents, or high‑grade pigments — high‑purity MnCO₃ with minimal impurities is strongly recommended. When sourcing or producing MnCO₃, emphasize impurity control and transparency: this protects product performance — and your reputation.

FAQ

Q1: What are the main impurities in manganese carbonate (MnCO₃)?

A1: Common impurities include iron (Fe), calcium (Ca), magnesium (Mg), silicon (Si), chlorides (Cl⁻), sulfates (SO₄²⁻), and trace heavy metals like lead (Pb), cadmium (Cd), or zinc (Zn). Levels vary depending on the grade (technical vs high-purity).

Q2: How do impurities affect battery applications?

A2: Impurities like Fe, Ca, and Mg can reduce cathode stability, cause side reactions, and accelerate capacity fading in lithium-manganese-oxide or NCM battery materials. High-purity MnCO₃ is recommended for battery use.

Q3: Can impurities impact ceramics, glass, or pigments?

A3: Yes. Iron may change color, silica can alter melting points, and chlorides or sulfates may cause defects like bubbles or inclusions in the final product.

Q4: How are impurities controlled in MnCO₃ production?

A4: Suppliers control impurities by selecting high-quality ore, using acid leaching and washing steps, testing with ICP-OES or ICP-MS, and offering high-purity grades with clear specifications.

Q5: What should buyers look for when choosing MnCO₃?

A5: Buyers should check the specification sheet for impurity limits, request analytical reports, confirm particle size and insoluble matter, and choose the right grade for their application (technical vs high-purity).

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.