Water content in manganese carbonate (MnCO₃) plays a key role in determining its purity, stability, and suitability for industrial applications. Even a small variation in moisture level can affect its performance in batteries, ceramics, catalysts, and fertilizer production. This blog explains what water content means, how it is measured, what standards define acceptable limits, and why it matters for both manufacturers and buyers of manganese carbonate.

I. What Is Water Content in Manganese Carbonate?

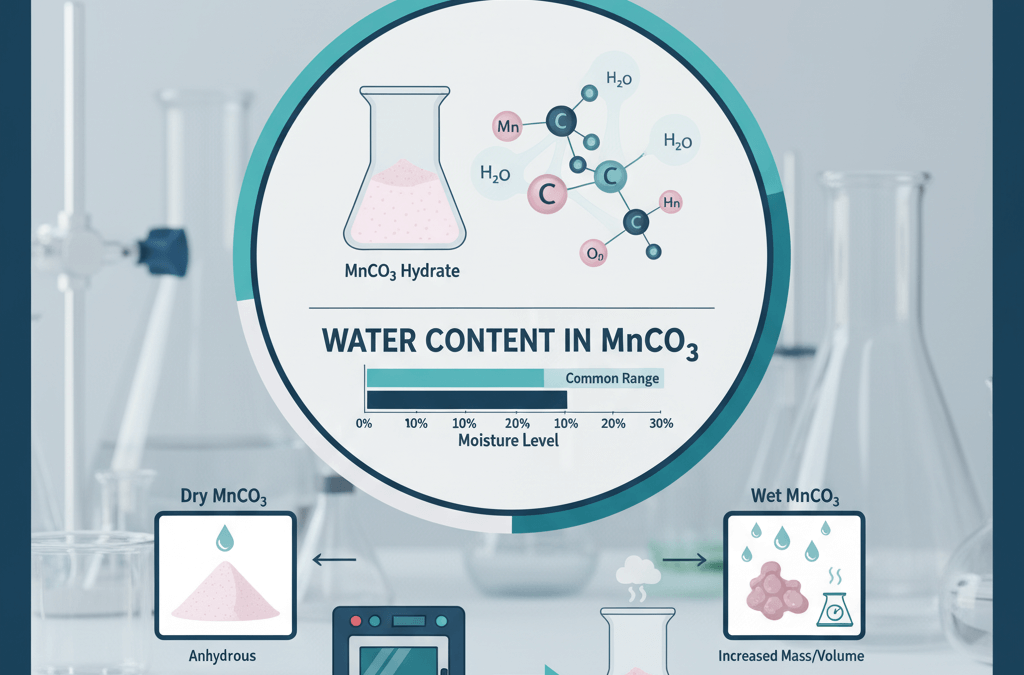

“Water content” refers to the amount of water associated with a sample of manganese carbonate. This may include:

Free or surface moisture (adsorbed water)

Bound water (crystallization or hydration water)

In many cases, MnCO₃ is specified as an anhydrous carbonate (MnCO₃) with minimal water uptake. Yet in practice powders may pick up moisture from atmosphere, or may contain small amounts of hydration.

For example: one academic study of amorphous manganese carbonate found water contents “nH₂O” around 1.09 ± 0.04 mol H₂O per mole MnCO₃ for one sample (≈1.09 mol water) and 1.32 ± 0.19 mol H₂O for another.

But industrial standards and product datasheets for MnCO₃ may instead target moisture values in weight percent—often ≤ 0.5% by weight.

In other words: if a batch of MnCO₃ weighs 100 g, the moisture (water) may ideally be no more than 0.5 g (0.5%).

Why include this measure? Because moisture content affects quality, processing behavior, weight‐based dosing, shelf/stability, caking, bulk density, and downstream conversion efficiency.

In terms of specification typical for high‐purity MnCO₃: moisture ≤0.5% (as noted in one QC checklist) is an accepted standard.

Also, the international standard for water determination in chemical solids is the ISO 760:1978 “Determination of water — Karl Fischer method (General method)”.

So in manufacturing/purchasing contexts: one speaks of “moisture content” or “water content” in MnCO₃, and controlling it is a mark of good quality.

II. Why Water Content Matters

A. Impact on downstream conversion (battery materials)

Many manganese carbonate products serve as precursors for manganese dioxide (MnO₂) or lithium manganese phosphate battery materials. If the MnCO₃ has higher moisture content:

The extra water means reduced “dry” mass of active material (you pay/weight but some mass is water) → lowers effective yield.

During thermal conversion (for example, calcination to MnO₂) the moisture must be removed (evaporation) which consumes energy and may create undesirable pore formation or micro‐cracking in derived products.

Moisture may promote oxidation or hydrolysis of MnCO₃ prematurely (especially if stored in humid conditions), which could affect reactivity, morphology or surface area of derived Mn compounds.

Thus for battery grade MnCO₃, lower moisture content (e.g., ≤0.5%) supports higher purity conversion, more predictable performance and better repeatability.

B. Impact on ceramics, catalysts, other industrial uses

In ceramics, pigments or catalyst manufacturing:

Moist water in MnCO₃ may create clumping, blocks, poor flowability.

During firing, residual moisture will be released — if large volumes of water vapor evolve it may cause pores or structural faults in final product.

Storage stability: in humid climates, powders with higher moisture may cake, stick, or absorb more water, altering bulk density and causing shipping/packing issues.

Therefore, a strict moisture specification ensures consistent behavior in handling, storage, and processing.

C. Storage, transport and logistics

From a logistics perspective:

Moist material will weigh more (includes water), but less “active material” per kilogram.

Moisture may cause increased humidity in packaging, risk of condensation, or even microbial growth in rare cases (if some organic contaminants exist). One note: a QC article states that moisture above 1.0% can cause lumping and microbial growth during storage in humid climates.

For powders shipped in bulk or bags, higher moisture may increase risk of clumping, bridging in hoppers, or require de‐dusting/sieving.

Hence moisture control reduces risk and supports consistent supply chain performance.

D. Summary Table

| Application area | Acceptable moisture content* | Potential issues if too high |

|---|---|---|

| Battery precursor MnCO₃ | ≤ 0.5% by weight (typical) | Lower yield, unexpected water in calcination, morphology change |

| Ceramic pigment/catalyst grade | ≤ 1.0% by weight (typical) | Caking, firing defects, inconsistent behavior |

| Storage & transport bulk powder | ≤ 1.0% by weight (target) | Clumping, bridging, stability issues |

| * Based on industrial practice (see sources above) |

In short: controlling water content is both a quality control metric and a practical manufacturing/logistics necessity.

III. How to Measure Water Content in Manganese Carbonate

Accurate measurement of water (moisture) is essential to verify that MnCO₃ meets specification. Here are typical methods, advantages, limitations, and recommended practices.

A. Common testing methods

Karl Fischer Titration

The international standard ISO 760:1978 defines a general method for determining free water or water of crystallization in most solid or liquid chemical products, using Karl Fischer titration.

According to a technical manual: it is highly accurate, suitable even for moisture levels in ppm range.

Advantage: very low detection limit, good for high‐purity materials.

Limitations: requires proper solvent system, may need sample dissolution or extraction, and careful calibration of reagent.

Loss on Drying / Oven Drying (Gravimetric method)

A sample is weighed, dried in an oven (often 105 °C) for a set time (e.g., 2 hours), then weighed again. The weight loss approximates moisture content.

For example, a blog article suggested: “A sample is dried at 105 °C ± 5 °C for 2 hours, and the weight loss is recorded. Acceptable limit: ≤0.5% moisture.”

Advantage: simple equipment, accessible for factories.

Limitations: may lose volatile components other than water, may not capture bound water well, lower accuracy for very low moisture levels.

Thermogravimetric Analysis (TGA)

In some research settings, TGA is used to measure mass loss versus temperature, showing dehydration steps (e.g., the study of amorphous MnCO₃ used TG‐DSC to observe dehydration and decomposition).

Advantage: detailed insight into water loss behavior; limitation: more expensive equipment, less typical for routine QC.

B. Recommended testing practice for manganese carbonate

For factory QC: Use oven drying at 105 °C for 2 h (or until constant weight) to get routine moisture check.

For high‐end/battery‐grade material: Use Karl Fischer titration to validate moisture at very low levels (e.g., ≤0.5%).

Ensure sample size and preparation follow standard procedure (e.g., sample ~2 g, uniform powder, avoid surface moisture from handling).

Record batch‐wise moisture results, trend them over time to detect drying/handling changes.

If using Karl Fischer, calibrate reagents and follow ISO 760:1978 method.

Provide a Certificate of Analysis (COA) for each batch showing moisture content, date, method.

C. Example values and interpretation

Suppose your batch of MnCO₃ shows moisture = 0.35% by oven drying – then 99.65% of the weight is “dry” material, meaning better value and consistent processing.

If a batch showed 1.2% moisture, then ~1.2 kg water per 100 kg material – impacts weight billing, process energy, transport cost.

QC standard target: moisture ≤0.5% (for high‐purity grade) is reasonable based on market documentation.

Accurate measurement of water (moisture) is essential to verify that MnCO₃ meets specification. Here are typical methods, advantages, limitations, and recommended practices.

A. Common testing methods

Karl Fischer Titration

The international standard ISO 760:1978 defines a general method for determining free water or water of crystallization in most solid or liquid chemical products, using Karl Fischer titration.

According to a technical manual: it is highly accurate, suitable even for moisture levels in ppm range.

Advantage: very low detection limit, good for high‐purity materials.

Limitations: requires proper solvent system, may need sample dissolution or extraction, and careful calibration of reagent.

Loss on Drying / Oven Drying (Gravimetric method)

A sample is weighed, dried in an oven (often 105 °C) for a set time (e.g., 2 hours), then weighed again. The weight loss approximates moisture content.

For example, a blog article suggested: “A sample is dried at 105 °C ± 5 °C for 2 hours, and the weight loss is recorded. Acceptable limit: ≤0.5% moisture.”

Advantage: simple equipment, accessible for factories.

Limitations: may lose volatile components other than water, may not capture bound water well, lower accuracy for very low moisture levels.

Thermogravimetric Analysis (TGA)

In some research settings, TGA is used to measure mass loss versus temperature, showing dehydration steps (e.g., the study of amorphous MnCO₃ used TG‐DSC to observe dehydration and decomposition).

Advantage: detailed insight into water loss behavior; limitation: more expensive equipment, less typical for routine QC.

B. Recommended testing practice for manganese carbonate

For factory QC: Use oven drying at 105 °C for 2 h (or until constant weight) to get routine moisture check.

For high‐end/battery‐grade material: Use Karl Fischer titration to validate moisture at very low levels (e.g., ≤0.5%).

Ensure sample size and preparation follow standard procedure (e.g., sample ~2 g, uniform powder, avoid surface moisture from handling).

Record batch‐wise moisture results, trend them over time to detect drying/handling changes.

If using Karl Fischer, calibrate reagents and follow ISO 760:1978 method.

Provide a Certificate of Analysis (COA) for each batch showing moisture content, date, method.

C. Example values and interpretation

Suppose your batch of MnCO₃ shows moisture = 0.35% by oven drying – then 99.65% of the weight is “dry” material, meaning better value and consistent processing.

If a batch showed 1.2% moisture, then ~1.2 kg water per 100 kg material – impacts weight billing, process energy, transport cost.

QC standard target: moisture ≤0.5% (for high‐purity grade) is reasonable based on market documentation.

IV. How a Factory Controls Water Content During Production

For a manufacturer of manganese carbonate aiming at low‐moisture product, the following production and QC measures are key.

A. Raw material and precipitation control

Use high‐purity manganese feedstock and manage precipitation so that after washing, the product has minimal entrained water.

After filtration, design washing steps to remove soluble impurities, then perform dewatering (vacuum filtration, centrifuge) before drying.

Maintain controlled pH, temperature and CO₂ flow in precipitation to reduce overspray/moist surfaces that retain moisture.

B. Drying and packaging

Dry the filtered cake/powder in ovens or fluid‐bed dryers, target temperature ~105 °C (or as per internal standard) until moisture target achieved (e.g., ≤0.5%).

After drying, cool in a dry atmosphere and then package immediately in moisture‐barrier bags (e.g., multi‐layer kraft+PE or aluminised).

Use desiccants within the packaging if needed, and store in low‐humidity warehouse.

Label each bag/batch with drying date, moisture test result, batch number.

C. Quality control & batch release

After drying and prior to packaging, take a representative sample of each batch for moisture measurement (oven or KF).

Record moisture, manganese content, particle size, insoluble matter. For example, one QC specification table shows Mn content ≥44.0%, moisture ≤0.5%.

Maintain batch‐wise logs and trend charts of moisture vs time to detect process drift.

If moisture exceeds internal limit (e.g., >0.8%), reject batch or re‐dry before shipping.

Offer test reports to buyers showing “Moisture: 0.27% (by oven drying at 105 °C, 2 h)”.

D. Storage & transport logistics

Store packaged bags on pallets, off the floor, in a dry warehouse (relative humidity <60%).

Cover pallets during shipping to avoid exposure to rain/humidity.

For containers, ensure good ventilation, no free water, and include desiccant or super desiccant packs for longer shipments.

Instruct shipping/handling staff not to stack in wet or semi‐wet conditions that might cause condensation inside bags.

E. Illustration of factory data (example)

“Our factory consistently achieves average moisture in MnCO₃ batches < 0.2% by weight (oven drying method). Each batch is measured and recorded. Particle size D₅₀ ~10 µm, Mn content ~44.3%. Packaging: 25 kg kraft‐PE lined bags with desiccant. Storage humidity controlled at 50% RH. Shipment conditions: sealed container with humidity indicator card.”

Including such data and transparency builds trust for international buyers.

VI. Conclusion

Water (moisture) content in manganese carbonate is a small number but with big implications. For manufacturers and end-users alike, controlling and verifying moisture at low levels (e.g., ≤ 0.5% by weight) supports quality, process stability, logistics and downstream performance. Factories that implement rigorous drying, packaging and QC systems stand out. For brand owners and purchasers, specifying and sourcing low‐moisture MnCO₃ is a strategic decision. If you need high-purity manganese carbonate with tightly controlled moisture levels, reach out and ask for the latest COA, sample tests and moisture history.

FAQ

Q1: What is the typical acceptable moisture content for manganese carbonate?

A: For high-purity or battery-precursor grade MnCO₃, an industry‐typical specification is moisture ≤ 0.5% by weight.

For less demanding grades (ceramics or pigment), up to 1.0% can be acceptable, depending on user requirements.

Q2: Why not aim for absolutely zero moisture?

A: In practice, achieving absolutely zero moisture is unrealistic (trace adsorption, bound water, ambient humidity). Also, ultra‐dry material may require extra cost/energy. The goal is a low and stable moisture level that aligns with downstream needs.

Q3: Which measurement method should I use?

A: For routine QC, oven‐drying at 105 °C for 2 h is common. For high accuracy (e.g., battery‐grade) use Karl Fischer titration per ISO 760:1978.

Q4: How often should moisture be tested?

A: Each batch should be tested. Additionally, conduct trend analysis (weekly or monthly) to detect process drift. For critical grades, re‐test stored product periodically (e.g., after 3-6 months) to ensure no moisture uptake in storage.

Q5: What packaging considerations help maintain low moisture?

A: Use moisture‐barrier packaging (kraft‐PE, aluminised film), include desiccants, store in controlled‐humidity warehouse (RH < 60%), avoid exposure to rain/humidity during transport, seal containers properly.

Q6: How does moisture affect downstream calcination or oxide conversion?

A: Moisture means extra energy to evaporate water before reaction, possible pore formation or morphological changes in derived oxide, lower effective “dry” yield of active material, and potential handling/storage issues (caking, slow reaction). Lower moisture improves predictability and quality.

Q7: Can I ask the supplier for a moisture history or batch COA?

A: Yes — a good supplier will provide a Certificate of Analysis showing moisture result, method used, test date, batch number. They may also provide past trend data, and information on drying/packaging/storage process.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.