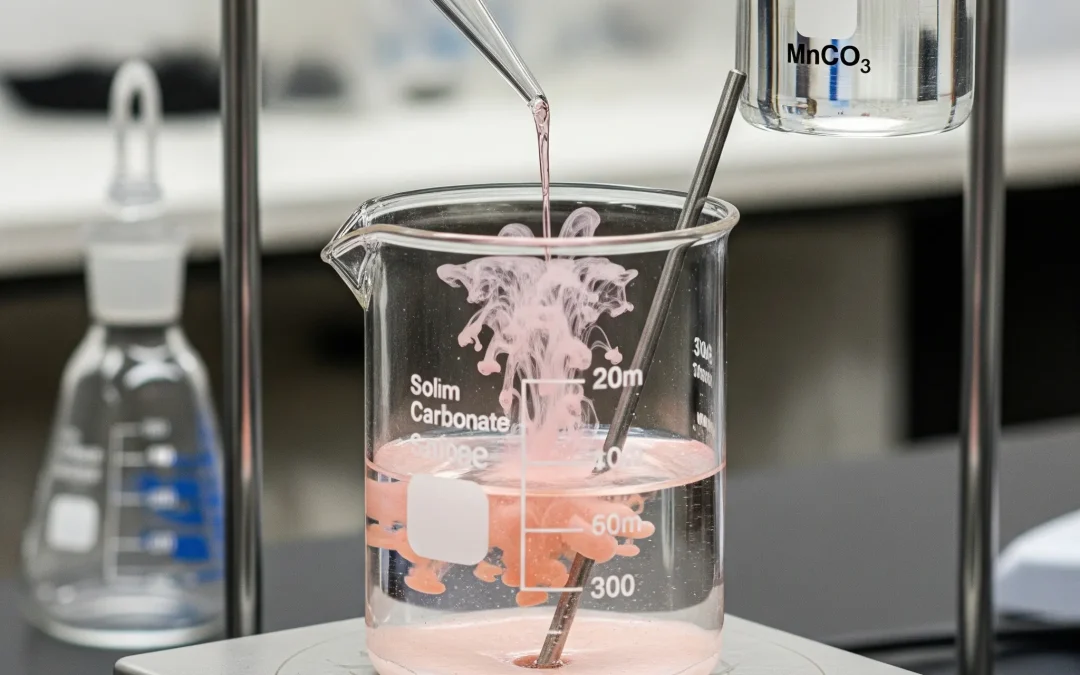

Manganese carbonate (chemical formula MnCO₃) is an important manganese compound used in many industries, including steel, batteries, fertilizers, and ceramics. For beginners in chemistry, this compound is a good example of how minerals react in different chemical conditions.

II. Basic Chemical Properties of Manganese Carbonate

Chemical formula: MnCO₃

Molecular weight: 114.95 g/mol

Appearance: Pale pink solid, crystalline or powder form

Density: ~3.12 g/cm³ (ICSD database)

Solubility: Poorly soluble in water (0.065 g/L at 25 °C, CRC Handbook of Chemistry and Physics)

Decomposition temperature: ~300–400 °C (produces MnO and CO₂)

Stability: Stable at room temperature, reacts with acids to form salts

???? Key point for beginners: MnCO₃ is stable under normal conditions but reacts strongly when heated or exposed to acids.

III. Common Chemical Reactions of Manganese Carbonate

Manganese carbonate participates in several important reactions. Below is a table that shows basic reactions, products, and conditions.

Table 1. Chemical Reactions of Manganese Carbonate

| Reaction Type | Chemical Equation | Products | Conditions / Notes | Source |

|---|---|---|---|---|

| Reaction with hydrochloric acid | MnCO₃ + 2HCl → MnCl₂ + CO₂↑ + H₂O | Manganese chloride, CO₂ gas, water | Room temperature | PubChem CID:101487 |

| Reaction with sulfuric acid | MnCO₃ + H₂SO₄ → MnSO₄ + CO₂↑ + H₂O | Manganese sulfate, CO₂ gas, water | Fertilizer & battery precursor | ScienceDirect, Hydrometallurgy |

| Thermal decomposition | MnCO₃ → MnO + CO₂↑ | Manganese(II) oxide, CO₂ | 300–400 °C | [CRC Handbook of Chemistry and Physics] |

| Oxidation of MnO (from decomposition) | 4MnO + O₂ → 2Mn₂O₃ | Manganese(III) oxide | 600–800 °C in air | [Journal of Thermal Analysis and Calorimetry, 2009] |

| Higher oxidation | 2Mn₂O₃ + O₂ → 4MnO₂ | Manganese dioxide | >800 °C | [Materials Science Reports, Elsevier] |

IV. Industrial Applications of These Reactions

Manganese carbonate is not just a chemical for labs; it is a key raw material for many industries. Its reactions form compounds that are essential in technology and manufacturing.

1. Steel Industry

MnCO₃ decomposes to MnO, which is used as a flux in steelmaking.

MnO removes sulfur and oxygen impurities, improving steel strength.

Typical dosage: 10–30 kg Mn per ton of steel (World Steel Association, 2022).

2. Battery Industry

MnCO₃ is a precursor for producing electrolytic manganese dioxide (EMD), widely used in alkaline and lithium batteries.

The process: MnCO₃ → MnO → MnO₂.

Battery-grade MnO₂ requires >99% purity (U.S. Geological Survey, 2023).

3. Fertilizers

MnSO₄ produced from MnCO₃ + H₂SO₄ is used as a micronutrient fertilizer.

Typical manganese content in fertilizers: 30–32% Mn.

Improves plant growth, prevents chlorosis (FAO guidelines on micronutrients, 2021).

4. Pigments and Ceramics

Decomposition products (MnO, Mn₂O₃) are used as pigments in ceramics and glass, giving brown and black colors.

V. Flow Diagram: Transformation Path

Here is a simple diagram showing how manganese carbonate transforms into other compounds:

MnCO₃ –(Heat 300–400 °C)–> MnO –(Oxygen, 600–800 °C)–> Mn₂O₃ –(Oxygen, >800 °C)–> MnO₂

VI. Comparison with Other Manganese Compounds

To understand the unique role of MnCO₃, it is helpful to compare it with MnO₂ and MnSO₄.

Table 2. Comparison of MnCO₃, MnO₂, and MnSO₄

| Compound | Chemical Formula | Typical Mn Content | Solubility | Main Applications | Source |

|---|---|---|---|---|---|

| Manganese Carbonate | MnCO₃ | 44–46% Mn | Poor solubility in water | Precursor for MnO, MnO₂; fertilizers; ceramics | [USGS Mineral Commodity Summaries, 2023] |

| Manganese Dioxide | MnO₂ | 63% Mn | Insoluble in water | Batteries (alkaline, Li-ion), oxidizing agent, pigments | [Electrochimica Acta, 2018] |

| Manganese Sulfate | MnSO₄·H₂O | 31–32% Mn | Highly soluble in water | Fertilizer micronutrient, feed additive, precursor for EMD | [FAO Micronutrients Report, 2021] |

???? MnCO₃ is best seen as a starting material, while MnO₂ and MnSO₄ are end-use compounds.

VII. Safety and Handling in Chemical Reactions

Dust control: MnCO₃ powder can cause respiratory irritation; use masks and ventilation.

Storage: Keep dry, avoid contact with acids to prevent CO₂ release.

Transport: Classified as non-hazardous but must follow local chemical transport regulations (OSHA, EU REACH).

???? Reference: U.S. Occupational Safety and Health Administration (OSHA), Hazardous Substance Fact Sheet – Manganese Compounds.

VIII. Beginner Takeaways

Manganese carbonate reacts with acids to form salts and CO₂.

Heating MnCO₃ produces MnO, which is useful in steel and batteries.

Further oxidation leads to Mn₂O₃ and MnO₂, both important industrial compounds.

Compared with MnO₂ and MnSO₄, MnCO₃ is mainly a precursor compound.

Safe handling is important for industrial and laboratory use.

IX. Frequently Asked Questions (FAQ)

Q1. What happens when manganese carbonate is heated?

It decomposes into manganese(II) oxide (MnO) and carbon dioxide gas.

Q2. Is manganese carbonate soluble in water?

No, it is poorly soluble (0.065 g/L at 25 °C), but it dissolves easily in acids.

Q3. Why is manganese carbonate important in industry?

Because it is a versatile raw material that can be converted into manganese dioxide, manganese sulfate, and other valuable manganese compounds.

Q4. Which industries use manganese carbonate the most?

Steel, batteries, fertilizers, and ceramics.

X. Conclusion

For beginners in chemistry, manganese carbonate offers an excellent example of how minerals behave in reactions. Its simple interactions with acids and heat lead to compounds that drive entire industries—from strong steel to modern batteries.

By understanding these basic reactions, students, researchers, and professionals can better appreciate why manganese carbonate is not just a chemical, but a gateway to multiple industrial processes.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.