You see more people want high-purity manganese sulfate EV battery materials now. Electric vehicles are gaining popularity very quickly, which increases the demand for manganese sulfate EV battery components. This surge in demand puts new pressure on the supply chain. Many companies are seeking safer sources for manganese sulfate EV battery production, and they also want to source it closer to home. This strategy helps them avoid running out of essential materials. If you work in this field, you should understand how the production of EV batteries with manganese sulfate EV battery inputs changes the landscape. It impacts where you source manganese sulfate and the methods you use to obtain it.

Manganese sulfate is very important for making strong EV batteries. It helps batteries last longer and stay safe.

More people want manganese sulfate because more electric cars are being made. Companies need to find good sources to get enough manganese sulfate.

When manganese sulfate prices stay steady, companies can plan battery costs better. This helps stop surprise money problems.

Having many suppliers is very important. Companies should work with different suppliers to stop shortages and delays.

Getting manganese sulfate in a good way helps the environment. It means less new mining and better care for nature.

Role in EV Batteries

Battery Chemistry

You need to know how manganese sulfate helps battery electric vehicles. Manganese sulfate is important for the cathode in many lithium-ion batteries. It is used in battery types like NMC and LNMO. These battery types let batteries hold more energy and last longer. Using high-purity manganese sulfate makes batteries safer and work better. Good manganese lowers the chance of battery problems. The manganese market is growing because companies want strong battery materials.

Tip: To make batteries better, use pure manganese sulfate. If there are impurities, batteries may not last as long or be as safe.

Applications in EVs

Many battery electric vehicles use manganese in their batteries. Car companies use manganese sulfate for batteries in cars, buses, and trucks. This material helps make batteries cheaper, so electric vehicles cost less. Manganese sulfate is also used in batteries for energy storage systems. These systems keep extra energy from wind and solar power. Picking manganese sulfate helps the supply chain focus on price and how well batteries work. The price of manganese sulfate does not change much compared to other battery metals. This helps you plan your costs. As more people want it, there will be more local sources and new ways to make manganese sulfate for EV batteries.

Manganese Sulfate EV Battery Market

Demand Trends

The need for manganese sulfate in batteries is growing fast. More electric vehicles are on the road each year. This means companies must make more batteries. They use more manganese sulfate EV battery materials now. High-purity manganese sulfate is needed for new battery chemistries. These batteries need pure manganese for the cathode to work well. Battery makers are competing more than before. Each company wants the best materials for the lowest price. This makes the manganese market feel more pressure.

Electric vehicles need better batteries, so demand for manganese sulfate has gone up.

Battery makers now compete to get high-purity manganese sulfate.

New battery technologies need manganese to work better.

Supply and demand can change fast if the supply chain has problems or if farming seasons change.

Sometimes, the market changes a lot when companies cannot get enough manganese sulfate.

Note: Watch for changes in supply and demand. These changes can make manganese sulfate cost more or be harder to find.

Price and Cost Impact

Manganese sulfate prices have gone up as more electric vehicles are made. The manganese market changes prices when demand goes up. Environmental rules and health worries about manganese mining can change costs. These rules can slow down how fast manganese sulfate is made or make it cost more. More people want renewable energy, so they need more manganese sulfate. Energy storage systems use batteries that need manganese. This helps the battery sector keep growing.

Manganese sulfate prices stay steadier than other battery metals. This helps you plan costs for battery electric vehicles. Manganese sulfate is a smaller part of the battery cost than cobalt or nickel. You can see this in the table below:

Battery Metal | Share of Total Battery Cost | Price Volatility |

|---|---|---|

Manganese | Low | Stable |

Nickel | High | Volatile |

Cobalt | High | Volatile |

Tip: You can plan your battery costs better with manganese sulfate. Stable prices help you avoid budget surprises.

Supply Chain Challenges

Manganese Sulfate Supply

Getting enough manganese sulfate for battery electric vehicles is hard. Sometimes, there is not enough supply for the demand. When demand is higher than supply, prices can rise. Only a few big producers control the manganese market. China makes most of the high-purity manganese sulfate EV battery supply. If something happens in China, you may not get what you need.

You should think about risks in your supply chain. If you depend on one country, you might face delays or shortages. Many companies want to make their supply chains stronger now. You can try different ways to help with this:

Use flexible shipping, like new routes or other transport, to avoid delays.

Make risk plans. These plans help you get ready for problems with getting or moving manganese sulfate.

Work with more suppliers in different places. This helps you avoid running out if one area has trouble.

Tip: If you plan ahead and use many sources, your supply chain stays strong and you can avoid big price jumps.

Regional Shifts

There are new changes in where companies make and process manganese sulfate. Many regions want to build their own supply now. This helps lower risks and keeps prices steady. The table below shows how regions affect supply chain strength for manganese sulfate:

Region | Key Factors Impacting Supply Chain Resilience |

|---|---|

Americas | North American policy incentives and localized manufacturing investments accelerating domestic battery-grade production. |

Latin America | Favorable mining jurisdictions but facing logistical constraints at port and rail terminals affecting global shipping economics. |

Europe, Middle East & Africa | Supply deficits due to decarbonization targets, increasing imports from South Africa and South America, and regulatory scrutiny. |

Asia-Pacific | Dominance in consumption and processing, with China controlling over 95% of high-purity manganese sulfate output. |

North America is building new plants to make manganese sulfate. This helps you get the material closer to where you need it. Latin America has good mining spots, but moving manganese to ports can be slow. Europe and Africa need more manganese for batteries, so they import more from other places. Asia-Pacific, especially China, still leads in making and using manganese sulfate for cathode materials.

If you want a strong supply chain, watch these regional changes. You can lower risks by working with suppliers in different parts of the world. This helps you keep up with the growing demand for manganese sulfate and handle price changes in the manganese market.

Sustainability

Environmental Impact

When you pick sustainable materials, you help electric vehicles. Manganese sulfate makes batteries last longer and stay safe. Cathodes with manganese keep batteries cool and safe. This helps electric vehicles work better. High-purity manganese sulfate helps the battery sector grow in a good way. You do not need new mines to make high-purity manganese sulfate. This means less harm to nature and land stays safe.

Cathodes with manganese make batteries safer.

Batteries work better and last longer with manganese sulfate.

Making high-purity manganese sulfate does not need new mining, so nature is safer.

Note: Choosing manganese sulfate for batteries helps clean energy and protects nature.

Responsible Sourcing

You should know where your manganese sulfate comes from. Responsible sourcing means checking how suppliers treat workers and nature. You can ask suppliers about their mining and how they process manganese sulfate. Many companies use audits to make sure suppliers follow safety and nature rules. Picking good suppliers helps the battery sector build trust.

Sourcing Practice | Benefit to You |

|---|---|

Supplier audits | Safer working conditions |

Less pollution | |

Local sourcing | Lower transport emissions |

Transparent supply chain | Easier to track materials |

Using responsible sourcing lowers risks and keeps your supply chain strong. It also helps keep manganese sulfate prices steady. Picking the right suppliers makes electric vehicles better for the planet. Responsible sourcing helps the battery sector and lets you reach future goals.

Future Trends

Battery Innovation

Big changes are coming to battery technology soon. Many companies want batteries to be safer and stronger. Solid-state batteries and lithium-manganese oxide chemistries lead this change. These new batteries need very pure manganese sulfate. Using high-purity manganese helps batteries store more energy. It also makes them last longer. Car makers want batteries that charge fast and keep people safe. Energy storage companies also want better battery materials. Because of this, manganese sulfate will be used more in battery electric vehicles. More people will want manganese sulfate EV battery materials as these new batteries become common. Li-ion batteries will still use manganese. But new battery types may need even purer manganese.

Note: New battery ideas mean you must watch for new material needs. High-purity manganese sulfate will stay important for future batteries.

Supply Security

You need to think about how to keep your supply chain strong. The supply and demand for manganese can change fast. If you only use one region, you might have delays or shortages. Many companies now build new plants in different countries. This helps you get manganese sulfate closer to where you make batteries. You can lower risks by working with more suppliers. Prices can change if supply drops or demand rises quickly. You should plan for these changes. A strong supply chain keeps your costs steady. It also helps you reach your goals.

Work with suppliers in different places.

Watch for changes in supply and demand.

Plan for price swings by having backup sources.

A safe supply of manganese sulfate helps you keep up with new battery trends. You can help battery electric vehicles grow and meet future needs for li-ion batteries.

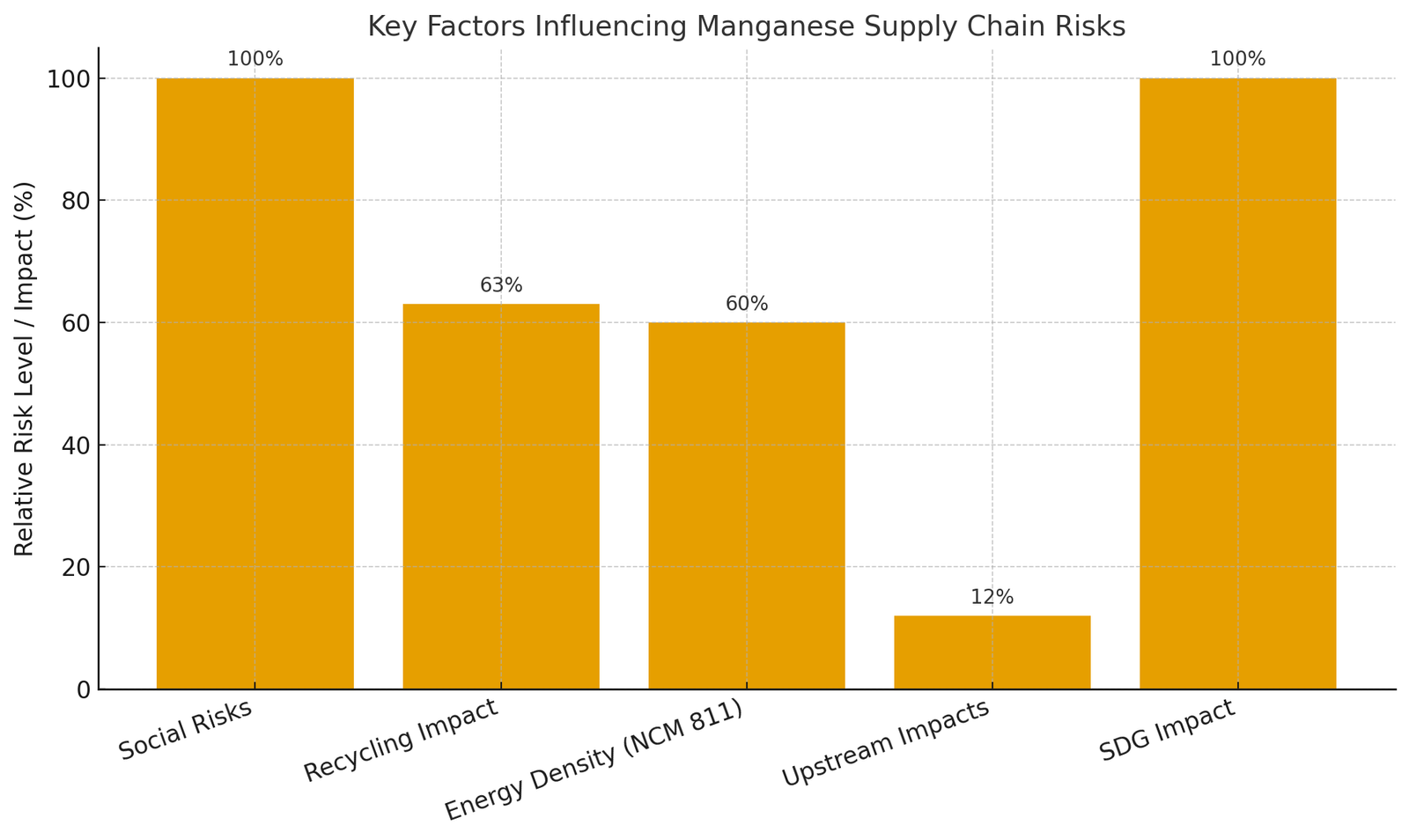

You help shape the future of the EV battery supply chain. If you focus on supply chain risks and care about sustainability, your business gets stronger. The table below explains why these things matter:

Key Findings | Description |

|---|---|

Social Risks | Problems with rules or corruption can hurt the supply chain. |

Recycling Impact | Recycling can lower social risks by almost 37%. |

Energy Density | NCM 811 batteries can cut social risks by over 40%. |

Upstream Impacts | About 12% of problems come from indirect upstream sources. |

SDG Impact | Getting raw materials affects world goals for peace and justice. |

You can find new chances as the market changes:

Better ways to make high-purity manganese sulfate

New ideas in battery manufacturing

Improved recycling technology

More money going into electric vehicles

Companies joining together for stronger supply chains

Growth in new markets

Watch these trends closely. You can change fast and become a leader in the battery industry.

FAQ

What is high-purity manganese sulfate?

High-purity manganese sulfate is a chemical for EV batteries. It is needed for battery cathodes. This chemical helps batteries hold energy and last longer. Battery makers pick it for safety and good performance.

Why does the EV industry prefer manganese sulfate?

Car makers use manganese sulfate to keep battery costs low. It also makes batteries safer for drivers. The price does not change much, so planning is easier. Manganese sulfate helps with new battery designs.

How can you reduce supply chain risks for manganese sulfate?

You can work with suppliers from many regions. You should check your supply sources often. Building local plants can help avoid delays. Planning for changes keeps battery production strong.

Is manganese sulfate safe for the environment?

Choosing high-purity manganese sulfate helps the environment. It does not need new mining, so nature is safer. Responsible sourcing and recycling lower pollution.

Will new battery technology change manganese sulfate demand?

Demand will grow as new batteries need purer manganese sulfate. Solid-state and advanced lithium batteries use more manganese. Watch for new trends to keep up with market changes.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.