The manganese dioxide market is categorized into two main purity groups based on the Purity Standard for Manganese Dioxide. One group has a purity of less than 99%, while the other exceeds 99%. High purity manganese dioxide, over 99%, is essential for use in electronics and specialty chemicals. Natural ore grades typically range between 20% and 80%, whereas electrolytic grades can reach purities as high as 99.9%. Adhering to the Purity Standard for Manganese Dioxide is crucial as it impacts applications in batteries, water purification, and ceramics. Complying with this purity standard ensures meeting strict regulations and quality requirements. Reliable suppliers like btlnewmaterial (manganesesupply.com) play a key role in driving growth and innovation in the market.

Key Takeaways

High purity manganese dioxide (above 99%) is very important. It is used in batteries, electronics, and water treatment. This helps things work better and keeps people safe.

Industry standards have strict rules about impurities. These include lead, arsenic, and sulfate. The rules help keep quality high and follow the law.

Good testing methods like XRF and ICP-OES are used. They check manganese dioxide purity fast and correctly.

Buyers should always look for certifications like ISO 9001. They should also ask suppliers for test reports. This helps make sure the product is safe and good quality.

Trusted suppliers like btlnewmaterial give certified high purity manganese dioxide. Their products meet industry needs and help new ideas grow.

Purity Standard for Manganese Dioxide

Purity Definition

In factories, the purity standard for manganese dioxide means how much manganese dioxide is in a sample compared to other things. Makers look at both the main part and the types of impurities that can change how it works. For high purity manganese dioxide, the most common impurities checked are titanium and sulfate. These can change how batteries work, like their voltage. The manganese valence is usually between 3.94 and 3.98, which is close to a perfect MnOx (x is about 1.97 to 1.99).

Note: The way manganese dioxide is made affects its purity standard. Chemical precipitation often makes high purity manganese dioxide with low heat and low cost. Other ways, like solid-phase synthesis, can add more impurities because they are sensitive to grinding and heat. Template methods can also lower purity if not done carefully.

Makers use different tests to check purity. The best way in factories is External Standard Calibration (EC). It measures Mn²⁺ levels fast and correctly. EC stops other ions from causing problems and makes little waste. This method helps watch purity in real time, which is important for big factories.

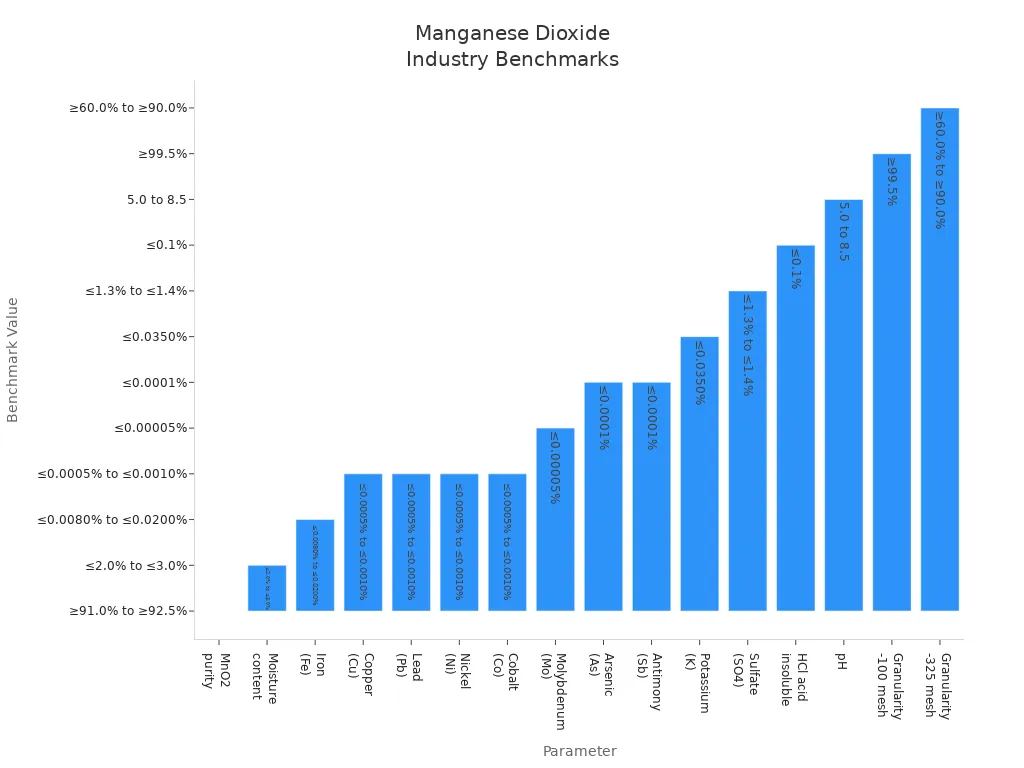

Industry Benchmarks

Industry benchmarks show what purity and quality high purity manganese dioxide should have. These rules make sure the material works well, especially in batteries. The table below shows the most common standards:

| Parameter | Typical Industry Benchmark | Notes / Application Context |

|---|---|---|

| Manganese dioxide (MnO₂) | ≥91.0% to ≥92.5% | Battery-grade purity for lithium, alkaline, C-Zn |

| Moisture content | ≤2.0% to ≤3.0% | Controls battery performance and stability |

| Iron (Fe) | ≤0.0080% to ≤0.0200% | Limits impurity for electrochemical efficiency |

| Copper (Cu) | ≤0.0005% to ≤0.0010% | Trace impurity limit |

| Lead (Pb) | ≤0.0005% to ≤0.0010% | Toxic impurity control |

| Nickel (Ni) | ≤0.0005% to ≤0.0010% | Impurity control |

| Cobalt (Co) | ≤0.0005% to ≤0.0010% | Impurity control |

| Molybdenum (Mo) | ≤0.00005% | Very low impurity level |

| Arsenic (As) | ≤0.0001% | Toxic impurity control |

| Antimony (Sb) | ≤0.0001% | Toxic impurity control |

| Potassium (K) | ≤0.0350% | Impurity control |

| Sulfate (SO₄ ion) | ≤1.3% to ≤1.4% | Limits sulfate content |

| Hydrochloric acid insoluble matter | ≤0.1% | Purity and quality control |

| pH | 5.0 to 8.5 | Ensures chemical stability |

| Granularity (-100 mesh) | ≥99.5% | Particle size distribution for battery performance |

| Granularity (-325 mesh) | ≥60.0% to ≥90.0% | Particle size distribution |

These standards are used by top makers and shown in reports. They help make high purity manganese dioxide for lithium, alkaline, and C-Zn batteries. The chart below shows how purity and impurities compare:

High purity manganese dioxide must have very low amounts of toxic things like lead, arsenic, and antimony. The amount of water and the size of the particles also matter for batteries. Companies like btlnewmaterial (manganesesupply.com) sell high purity manganese dioxide that meets these standards, helping with new uses and following rules.

Industry Requirements

Battery Applications

The battery industry needs high purity manganese dioxide. This helps batteries work well and last longer. Makers use it in zinc–carbon, alkaline, and lithium-ion batteries. High purity manganese dioxide keeps the voltage steady. It also helps batteries store more energy and last through many cycles. Electrolytic manganese dioxide is the best type because it has very few impurities. Battery-grade material must be over 91% pure. Some batteries need more than 99% purity. This high standard helps new energy storage systems work better. Companies want high purity manganese dioxide for new batteries and energy storage.

Ceramics and Glass

Ceramics and glass makers use manganese dioxide with different purity levels. Most of the time, they use medium purity (75%–90%) or low purity (below 75%). High purity manganese dioxide is not needed for these products. The industry uses flakes or granules to color or remove color from glass and ceramics. Lower purity grades are common, but they can change the color and strength of the final products. High purity manganese dioxide is only used for special jobs, not for most ceramics or glass.

Water Treatment

Water treatment systems use high purity manganese dioxide media. Purity is usually above 85% to work well. The media has small holes and even particle size. This helps remove bad things from water. Certified products, like those with NSF approval, make sure the media does not add harmful things like lead or arsenic. High purity manganese dioxide is important for safe and clean water.

High Purity Manganese Dioxide

High purity manganese dioxide is needed for advanced industry uses. Makers use chemical and electrolytic methods to take out impurities. Electrolytic manganese dioxide is known for being very pure and always the same. The battery industry needs this material for strong cathodes. High purity manganese dioxide also helps make ferrite and other special products. New powders with better features are being made for today’s needs. As more people want energy storage, high purity manganese dioxide becomes more important. Top suppliers like btlnewmaterial (manganesesupply.com) sell certified high purity manganese dioxide to meet tough industry rules.

Purity Measurement

Analytical Methods

Factories and labs use special tools to check high purity manganese dioxide. X-ray fluorescence (XRF) is a fast way to look at the surface. It does not damage the sample and is easy to use. XRF does not need much prep and can be moved around. Inductively coupled plasma optical emission spectrometry (ICP-OES) is another common method. ICP-OES and ICP-MS give very exact results for metal ions. These tests take longer but check the whole sample well. Studies show XRF and ICP-OES give almost the same results. This means both are good for checking high purity manganese dioxide. Spectrofluorimetric methods can find very tiny amounts. They can see as little as 1 ng/L and are very exact. These tests help make sure high purity manganese dioxide is good enough for industry.

Certification Standards

Industry rules help make sure high purity manganese dioxide is good quality. Groups like ASTM International and ISO make these rules. They say how to test high purity manganese dioxide and what impurities are okay. Labs that are certified follow these steps to check the material. Companies must give certificates to show they meet ASTM and ISO rules. This helps people trust high purity manganese dioxide for important jobs like batteries and water cleaning.

High Purity Manganese

High purity manganese, like high purity electrolytic manganese, must pass tough checks before use. Labs test it many times with XRF, ICP-OES, and other tools. They compare results to known samples and check if they are close, within 1.2–2.0%. Recovery rates are usually 98–100%, which shows the tests work well. Suppliers like btlnewmaterial (manganesesupply.com) sell high purity manganese dioxide with full certificates. This meets the needs of battery, water cleaning, and electronics makers. High purity manganese dioxide is needed for safety and good performance everywhere.

Sourcing and Market

Manganese Dioxide Market

The manganese dioxide market is getting bigger. More people want it for batteries, electronics, and water cleaning. In 2023, the market was worth USD 1.5 billion. By 2032, it could reach USD 2.8 billion. This means it grows about 7.2% each year. Asia Pacific is the top region, with about 45% of the market. China and India are growing fast, so they use more manganese dioxide. North America and Europe are next. They focus on electric cars and green energy. Battery grade manganese dioxide is the most used type. It is important for lithium-ion and alkaline batteries. Chemical and electronic grades are also growing. Prices can change because raw materials cost more or less. New technology can also change prices. Companies try to make better products and build more factories. This helps them stay ahead in the market. People are finding new ways to use manganese dioxide. It is now used more in water cleaning and chemical factories. Purified manganese sulfate solution is important for these new uses.

Aspect | Details |

|---|---|

Market Growth | CAGR ~7.2% (2025-2033); Market size from USD 1.5B (2023) to USD 2.8B (2032) |

Demand Drivers | Electric vehicles, electronics, renewable energy, water treatment, chemical industries |

Regional Supply/Demand | Asia Pacific: ~45% share; North America: ~25%; Europe: ~20% |

Product Types | Battery Grade, Chemical Grade, Electronic Grade |

Pricing Influences | Raw material volatility, competition from alternatives |

Market Competition | Innovation, capacity expansion, mergers and acquisitions |

Emerging Applications | Water treatment, chemical industry (oxidizing agent) |

Supplier Verification

People who buy manganese dioxide need to check their suppliers. They must make sure the product is good quality. Buyers should see if suppliers follow rules for safety and the environment. Good raw materials mean the product stays pure. A supplier with a good name is usually more trustworthy. Buyers should ask if the supplier has different purity grades. Some jobs need high purity or ultra-high purity. Suppliers must give what is needed for batteries or water cleaning. Knowing how the supplier makes manganese dioxide helps check quality. A strong supply chain means fewer problems. Suppliers who do research often have better products. Companies like btlnewmaterial (manganesesupply.com) sell many types of high purity manganese dioxide and purified manganese sulfate solution. They meet tough industry rules.

Tip: Always ask for papers and test results from another company before you buy.

Specification Review

It is very important to check the product details in the manganese dioxide market. Buyers should look for certificates like ISO 9001, IEC 60086, and RoHS. These show the product is safe and follows the rules. Good suppliers check raw materials, watch the process, and test the final product. They give full test reports with results for power, safety, and leaks. Tests from other companies help make sure the product is good. This keeps buyers safe from bad products. It also helps make sure batteries and other things work well. To learn more about certificates, visit ISO’s official website.

Aspect | Description |

|---|---|

Certifications | ISO 9001, IEC 60086, CE Marking, UN38.3, RoHS, regional certifications |

Quality Assurance Processes | Raw material inspection, in-process monitoring, final product testing |

Testing Methods | Capacity, discharge, leakage, safety, visual and dimensional inspections |

Role in Sourcing | Ensures purity, supplier reliability, compliance, safety, and performance |

Importance of Purity

Performance Impact

High purity manganese dioxide is very important for many products. Factories use it to make sure batteries and electronics work the same every time. The amount of purity changes how well these things work.

- High purity manganese dioxide (≥ 99%) makes batteries better. It helps batteries store more energy and last longer. This is important for electric cars and phones.

- Ultra-high purity manganese dioxide (up to 99.99%) is needed in electronics. Even tiny bits of other stuff can make semiconductors and magnets work worse.

- In special alloys, high purity manganese dioxide makes parts stronger. It also helps them not rust. Cars and airplanes use these strong, light parts.

- Water cleaning systems use high purity manganese dioxide to take out bad stuff. The pure material helps clean water safely.

- The shape of high purity manganese dioxide, like powder or granules, matters too. Powder works best for batteries.

Factories pick high purity manganese dioxide for new and better products. More companies want higher purity because it gives better results.

Compliance

Having pure manganese dioxide is not just about making things work well. It is also about being safe and following the law. Rules say there must be very little lead, arsenic, or antimony. These can hurt people and nature.

- Companies must follow world rules like ASTM and ISO. These rules say how much impurity is okay and how to test it.

- Certificates show that high purity manganese dioxide is safe and legal. Suppliers give these papers to prove it.

- If products do not meet the rules, they might get taken back or cause trouble. This is why following the rules is very important.

Note: Buyers should always ask for certificates and test results. Good brands like btlnewmaterial (manganesesupply.com) give all the papers to show their product is safe and good.

Following purity rules keeps people and the earth safe. It also helps companies stay out of trouble and keep a good name.

The manganese dioxide market uses strict rules to keep products good. High purity manganese dioxide is important for batteries, water cleaning, and electronics. Buyers must check for impurities like phosphorus, sulfur, and iron. The table below lists important things to watch:

| Parameter | Why It Matters in the Manganese Dioxide Market |

|---|---|

| Phosphorus | Changes steel and alloy quality |

| Sulfur | Can lower corrosion resistance |

| Moisture | Makes handling and moving harder |

| Particle Size | Affects how it is used in factories |

| Aluminum, Iron | Changes purity and alloy strength |

High purity manganese dioxide has to follow industry rules. The manganese dioxide market needs certificates and outside tests. Companies should check all details and papers before buying. This stops problems and keeps users safe. Good suppliers like btlnewmaterial (manganesesupply.com) help buyers get high purity manganese dioxide that meets every rule. The manganese dioxide market is getting bigger, so checking high purity manganese dioxide is always important for safety and how well it works.

Tip: Always look at official rules and papers to stop problems in the manganese dioxide market.

FAQ

What is the typical purity range for industrial manganese dioxide?

Industrial manganese dioxide is usually 80% to over 99% pure. Battery-grade types are often more than 91% pure. High purity, above 99%, is used in electronics and special chemicals. Source: U.S. Geological Survey.

Why does battery manufacturing require high purity manganese dioxide?

Battery makers need high purity manganese dioxide for steady voltage and safety. Impurities can make batteries work worse or even fail. The industry has strict rules about how much impurity is allowed.

How do suppliers verify manganese dioxide purity?

Suppliers use special tests like XRF and ICP-OES. They give certificates that follow ASTM and ISO rules. Trusted brands, like btlnewmaterial (manganesesupply.com), share all papers and test results from other labs.

What certifications should buyers look for when sourcing manganese dioxide?

Buyers should look for ISO 9001, IEC 60086, and RoHS certificates. These show the product is safe and follows the rules. Certificates from trusted groups prove the supplier meets the standards.

Where can buyers find reliable high purity manganese dioxide?

Buyers can get high purity manganese dioxide from trusted suppliers like btlnewmaterial (manganesesupply.com). Always ask for certificates and lab reports to make sure the product is good and safe.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.