Manganese dioxide powder needs careful handling and safe storage. MnO₂ can get ruined or dirty if it touches water or other chemicals. If people do not follow Storage and Handling Guidelines for MnO₂, accidents can happen and the material gets worse. MnO₂ dust can hurt your health, so safety is very important. Using the right ways to handle manganese dioxide powder keeps workers safe and keeps MnO₂ working well. Always be careful with manganese dioxide powder to stop dangers.

Key Takeaways

Store MnO₂ in sealed containers made of glass, HDPE plastic, or stainless steel to keep it dry and safe.

Keep MnO₂ in a cool, dry place with good airflow and away from materials it can react with.

Always wear gloves, goggles, and masks when handling MnO₂ to protect your skin, eyes, and lungs.

Control dust by using fume hoods, wet cleaning, or HEPA vacuums to keep the air clean and safe.

Check MnO₂ often for changes like clumps or wet spots and keep records to maintain its quality.

Containers

Materials

It is important to pick the right container for storing MnO₂. Glass, high-density polyethylene, and some metals are good choices. Each type of container has its own good points. Glass does not react with chemicals and does not soak up MnO₂. High-density polyethylene containers are light and strong. Stainless steel containers keep MnO₂ safe from things outside. The container should not react with manganese dioxide powder. Using the right container keeps MnO₂ good and lowers danger.

Sealing

A container that closes tightly keeps MnO₂ safe. Good sealing stops water from getting in and keeps MnO₂ clean. Workers need to make sure the lid fits well. If the lid is loose, air, dust, or water can get to MnO₂. Many places use screw-top or clamp-sealed containers for more safety. Sealing the container well keeps MnO₂ dry and safe while it is stored.

Tip: Always check the container seal before and after using it to keep MnO₂ safe.

Labeling

Every container needs a clear label. The label should have “manganese dioxide powder,” the formula MnO₂, and warning signs. Labels help workers know what is inside and use the container safely. The label should also have the date and the name of the person in charge. Good labels stop mistakes and keep people who should not use it away. Keeping containers in a locked place makes them even safer.

Container Type | Benefits | Suitability for MnO₂ |

|---|---|---|

Glass | Does not react, does not soak up | Excellent |

HDPE Plastic | Strong, light, does not react | Good |

Stainless Steel | Strong, does not rust | Good |

Storage Conditions

Temperature

The best temperature for MnO₂ keeps it safe and stable. Experts say to store it in a cool place, between 15°C and 25°C. If it gets too hot, MnO₂ can break down or react with other things. Do not put MnO₂ near heaters or in sunlight. Storing it right keeps MnO₂ good and stops accidents. Check the temperature often to make sure the powder is okay.

Humidity

It is very important to control humidity for MnO₂. Water in the air can make the powder stick together or not work well. Too much humidity can cause it to get dirty or change. Keep MnO₂ in a dry place with less than 60% humidity. Put desiccants in the container to soak up extra water. Watch the humidity to keep the powder safe and stored right.

Note: Always look for wet spots or clumps in the container. If you see them, change the powder and make the storage better.

Ventilation

Good airflow in the storage room stops dust and fumes from building up. Air moving around helps stop people from breathing in MnO₂ dust. Keep doors open or use fans to move air in the room. Airflow also helps keep the room cool and dry. This keeps both the powder and workers safe.

Separation

MnO₂ should not be near things it can react with. Reducing agents, combustibles, organics, and some metals can be dangerous with MnO₂. Store MnO₂ on its own shelf or in a different cabinet. Lock or secure the storage area to stop others from getting in or mixing things by mistake. Keeping MnO₂ apart from other things lowers the chance of bad reactions.

For more about what chemicals are safe, visit the U.S. Occupational Safety and Health Administration (OSHA) website.

Storage and Handling Guidelines for MnO₂

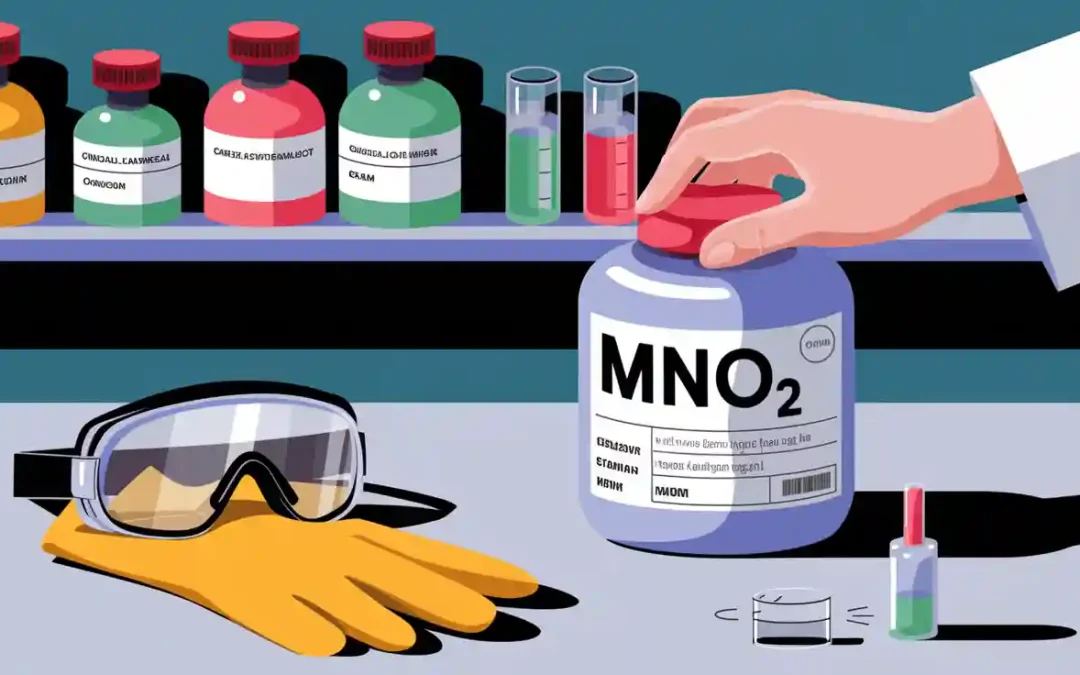

PPE

Workers need to wear personal protective equipment with MnO₂. Gloves keep the powder off your skin. Safety goggles stop dust from getting in your eyes. Lab coats or coveralls keep powder off your clothes and body. Respirators or dust masks help you not breathe in MnO₂. Everyone should check their gear before using it. The right PPE is the first way to stay safe with MnO₂.

Tip: Change gloves or masks if they get damaged to stay safe.

Dust Control

MnO₂ makes fine dust that can spread fast. Workers should use closed systems or fume hoods when moving the powder. Wetting surfaces helps keep dust from floating up. HEPA vacuums clean up dust without spreading it. Never use a dry broom on manganese dioxide powder. These steps help stop people from breathing in MnO₂ and keep the area clean. Dust control is very important for safe storage and handling of MnO₂.

Dust Control Method | Effectiveness | Notes |

|---|---|---|

Fume Hood | High | Use during weighing or mixing |

Wet Cleaning | Medium | Use water sparingly |

HEPA Vacuum | High | Avoids dust dispersal |

Hygiene

Good hygiene keeps workers safe and MnO₂ clean. Workers must wash hands after touching or moving the powder. Do not eat, drink, or smoke where MnO₂ is stored. Change work clothes after each shift so powder does not leave the lab. Clean work areas often to get rid of any powder left behind. These hygiene rules help keep MnO₂ pure and safe.

Spill Response

If MnO₂ spills, act fast. Put on all your PPE before cleaning up. Use a HEPA vacuum or a wet cloth to pick up the powder. Put all waste in a sealed and labeled container. Let fresh air into the room to clear out dust. Tell your supervisor about big spills and follow safety rules. Cleaning up spills the right way is very important for safe storage and handling of MnO₂.

Alert: Never use compressed air to clean MnO₂ spills. This makes dust spread and can hurt your health.

Following these storage and handling rules for MnO₂ lowers risks and keeps manganese dioxide powder safe to use. Every step, from PPE to spill cleanup, helps make the workplace safer and keeps the powder good.

Manganese Dioxide Powder Monitoring

Visual Checks

Workers look at manganese dioxide powder often to find problems. They check if the color or texture changes or if it clumps. If MnO₂ looks lighter than usual, it might not be as good. Lumps or hard pieces can mean there is too much water. Workers use a flashlight to look inside the container and check the top of the powder. If they see anything wrong, they tell someone right away. These checks help keep MnO₂ safe and good to use.

Moisture and Contamination

Water can make MnO₂ go bad. Workers use test strips or meters to check for water. They look for leaks or wet spots in the storage area. If there is too much water, they add new desiccants and move the powder to a dry spot. Dust, other chemicals, or air can also make MnO₂ dirty. Workers keep MnO₂ away from open windows and vents. They always use clean tools when touching the powder. By keeping out water and dirt, they keep MnO₂ good.

Note: The U.S. Environmental Protection Agency (EPA) says to check for water and dirt often to keep chemicals safe. Learn more at epa.gov.

Record-Keeping

Writing things down helps workers watch the quality of MnO₂. They write the date, what the powder looks like, and how much water is in it. They also note how much MnO₂ they use and when they open new containers. This helps them see if there are any problems over time. A table or logbook makes it easy to look back at old checks.

Date | Inspector | Condition | Moisture Content | Notes |

|---|---|---|---|---|

2024-06-01 | J. Smith | No clumps, dark | 0.2% | All good |

2024-06-08 | L. Brown | Slight clumping | 0.5% | Changed silica |

By checking MnO₂ often, workers keep the manganese dioxide powder safe and ready to use later.

Disposal

Waste Handling

Good waste handling keeps people and nature safe. Workers must put all waste with MnO₂ in closed, labeled containers. They should not pour MnO₂ down the sink or throw it in the trash. Instead, they use containers that do not react with MnO₂, like glass or high-density polyethylene. These containers must stay shut when not being used. Workers keep the waste in a special spot until a trained waste company picks it up.

A simple way to handle waste is:

Put on personal protective equipment before touching MnO₂ waste.

Use a scoop or brush to pick up spilled powder.

Put all MnO₂ and cleaning tools in a closed container.

Write the contents and date on the label.

Keep the container in a safe, airy place.

Tip: Always have a spill kit close by to clean up MnO₂ waste fast and safely.

Regulatory Compliance

Following rules makes sure MnO₂ is thrown away safely and legally. Workers must obey all local, state, and federal laws for hazardous waste. The U.S. Environmental Protection Agency (EPA) says MnO₂ is a hazardous material. Places must sign up as hazardous waste makers and write down all MnO₂ disposal steps. They should only use trained waste companies to move and treat the waste.

A table of important rule steps:

Step | Description |

|---|---|

Identify Waste | Make sure the waste has MnO₂ |

Label and Store | Use the right labels and safe storage |

Document Disposal | Write down all MnO₂ waste movements |

Use Licensed Handlers | Hire trained hazardous waste companies |

Note: For more about hazardous waste rules, visit epa.gov.

Doing these steps helps groups avoid fines and keeps the environment safe when getting rid of MnO₂.

Safe management of MnO₂ means using the right steps.

Put MnO₂ in a cool, dry place with good airflow.

Do not let it touch things it should not mix with.

Always wear gloves, goggles, and dust masks when handling.

Check the powder often and watch for any wetness.

Throwing away MnO₂ the right way keeps people and nature safe. It stops heavy metals from building up in dirt and water. Groups that do these things help keep everyone safe for a long time.

FAQ

What are the main hazards of handling manganese dioxide powder?

Manganese dioxide powder can bother your nose and skin. Workers need to wear safety gear when using it. The Centers for Disease Control and Prevention (CDC) has more safety tips at cdc.gov.

Can manganese dioxide powder be used in lithium batteries?

Many scientists use manganese dioxide powder in lithium batteries. The special structure of mno2 helps batteries work better and safer.

Why is dust control important during the synthesis of mno2?

Dust control stops people from breathing in tiny particles. It also helps keep the shape of mno2 the same. Good dust control makes making mno2 safer and keeps it high quality.

How does manganese dioxide contribute to energy storage and conversion?

Manganese dioxide has great electrochemical properties of mno2. Scientists use it in supercapacitors and other energy devices. Its nanostructured mno2 form helps these devices work better.

How should workers monitor the quality of manganese dioxide powder?

Workers need to look for changes in color, texture, or clumps. Checking often helps keep the structural properties of mno2 stable. Writing down what they see helps find problems over time.

Related Posts

I am Edward lee, founder of manganesesupply( btlnewmaterial) , with more than 15 years experience in manganese products R&D and international sales, I helped more than 50+ corporates and am devoted to providing solutions to clients business.